Content Menu

● Introduction to Ringlock Scaffolding

● Components of Ringlock Scaffolding

● Additional Ringlock Scaffolding Parts

● Applications of Ringlock Scaffolding

● Safety Considerations for Ringlock Scaffolding

● Maintenance and Storage of Ringlock Scaffolding Parts

● Comparison with Other Scaffolding Systems

● Conclusion

● FAQ

>> 1. What are the main components of Ringlock scaffolding?

>> 2. How do Ringlock scaffolding parts contribute to stability?

>> 3. What are some additional Ringlock scaffolding parts?

>> 4. What are the applications of Ringlock scaffolding?

>> 5. Why is Ringlock scaffolding preferred in construction?

● Citations:

Ringlock scaffolding is a modular system widely used in construction and industrial applications due to its versatility, efficiency, and safety features. The system consists of several essential components that work together to provide a stable and secure working platform. Understanding these Ringlock scaffolding parts is crucial for effective assembly, safe operation, and efficient project execution. In this article, we will delve into the main components of Ringlock scaffolding, their functions, and how they contribute to the overall stability and effectiveness of the system.

Introduction to Ringlock Scaffolding

Ringlock scaffolding is designed to support complex structures and facilitate quick assembly and disassembly. Its modular design allows for flexibility in construction projects, making it suitable for various applications such as facade scaffolding, rebar scaffolding, and trench bridges. The system's flexibility and stability make it ideal for building circular or straight structures, as well as supporting complex architectural designs.

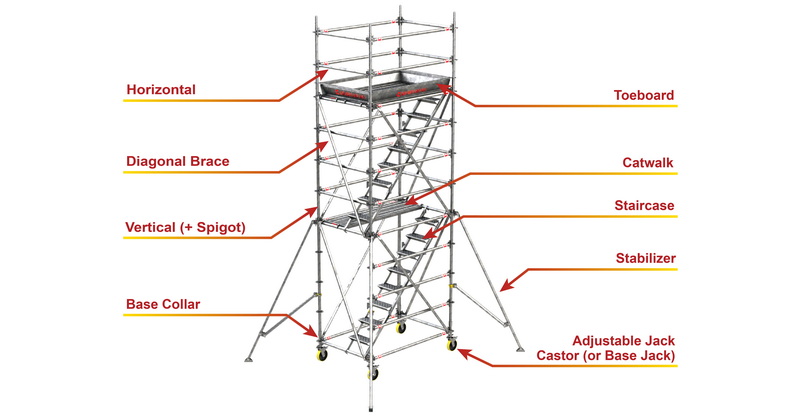

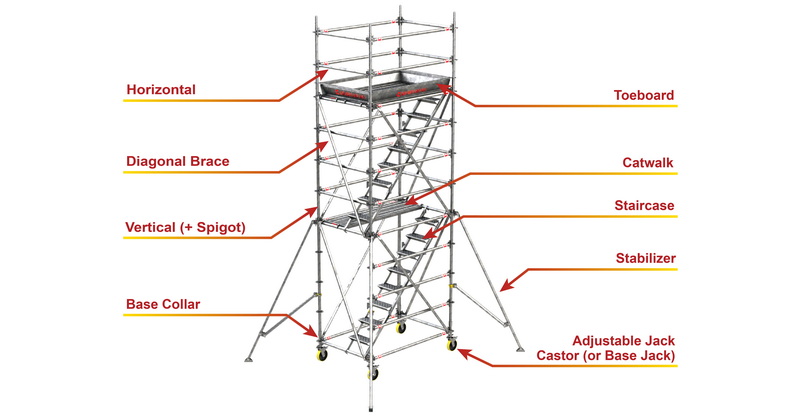

Components of Ringlock Scaffolding

The Ringlock scaffolding parts can be categorized into several key components:

- Standards (Vertical Components): These are the main load-bearing structures of the scaffolding system. They provide vertical support and determine the height of the scaffold. Standards typically feature rosettes at regular intervals (e.g., every 0.5 meters) for connecting other components.

- Ledgers (Horizontal Components): These connect standards horizontally, forming the outer framework of the scaffold. Ledgers contribute to the overall stability of the structure and help distribute the load. They are often used as handrails and feature a cast end with a captive wedge for secure connections.

- U-Transoms: These are horizontal components placed between ledgers to support scaffolding planks. U-Transoms enhance the load-bearing capacity and provide a stable working platform.

- Diagonal Braces: These components provide additional stability to the scaffolding structure by forming a rigid framework. Diagonal braces are connected to the standards and ledgers using a swivel cast end with a captive wedge.

- Steel Decks (Platforms): These are the platforms on which workers stand. They are designed to be durable and provide a safe working surface.

- Base Jacks, Plates, or Caster Wheels: These components are used to create a stable foundation for the scaffold. They can be bolted or clamped to the surface to ensure stability.

Additional Ringlock Scaffolding Parts

Besides the main components, there are several other Ringlock scaffolding parts that enhance the system's functionality and safety:

- Rosette Rings: These are integral to the standards and allow for the connection of ledgers and diagonal braces. Rosette rings are typically spaced at regular intervals to provide multiple attachment points.

- Wedge Pins: Used in ledger heads and diagonal braces to secure connections to the rosette rings.

- Brace Heads: These are part of the diagonal braces and feature a swivel cast end with a captive wedge for secure connections.

- Stair Beams and Steps: Provide safe access to higher levels of the scaffold.

- Adapters: Allow for customization and adaptation to specific project requirements.

Applications of Ringlock Scaffolding

Ringlock scaffolding is widely used in various construction projects due to its versatility and efficiency:

- Facade Scaffolding: Ideal for tasks such as bricklaying, painting, and window installation.

- Rebar Scaffolding: Used for reinforcement and formwork in concrete structures.

- Trench Bridges and Stair Towers: Provides safe access for workers in excavation sites and multi-story buildings.

Safety Considerations for Ringlock Scaffolding

Ensuring safety is paramount when using Ringlock scaffolding. Here are some key considerations:

- Regular Inspections: Regularly inspect scaffolding components for damage or wear.

- Proper Assembly: Ensure that the scaffolding is assembled according to the manufacturer's instructions.

- Load Capacity: Never exceed the recommended load capacity of the scaffolding.

- Personal Protective Equipment (PPE): Ensure workers use appropriate PPE when working on scaffolding.

Maintenance and Storage of Ringlock Scaffolding Parts

Proper maintenance and storage of Ringlock scaffolding parts are essential for extending their lifespan and ensuring safety:

- Cleaning: Regularly clean components to prevent corrosion.

- Storage: Store components in a dry area to prevent rust and damage.

- Inspection: Regularly inspect components for signs of wear or damage.

Comparison with Other Scaffolding Systems

Ringlock scaffolding is often compared to other systems like Cuplock scaffolding. While both are modular, Ringlock is generally considered more stable and easier to use due to its wedge-head locking mechanism and the formation of a stable triangular structure.

Conclusion

Understanding the essential Ringlock scaffolding parts is crucial for effective use and safety in construction projects. By recognizing the functions of each component, from standards and ledgers to diagonal braces and steel decks, you can ensure a stable and efficient scaffolding system. Whether it's used for complex architectural designs or standard construction tasks, Ringlock scaffolding is a reliable and efficient solution.

FAQ

1. What are the main components of Ringlock scaffolding?

The main components of Ringlock scaffolding include standards (vertical components), ledgers (horizontal components), U-transoms, diagonal braces, steel decks, and base jacks.

2. How do Ringlock scaffolding parts contribute to stability?

Ringlock scaffolding parts contribute to stability through secure connections between standards, ledgers, and diagonal braces. The rosette rings and wedge pins ensure a rigid framework that distributes loads effectively.

3. What are some additional Ringlock scaffolding parts?

Additional parts include rosette rings, wedge pins, brace heads, stair beams, steps, and adapters. These components enhance the system's functionality and safety.

4. What are the applications of Ringlock scaffolding?

Ringlock scaffolding is used in various applications such as facade scaffolding, rebar scaffolding, trench bridges, and stair towers. It is suitable for both simple and complex construction projects.

5. Why is Ringlock scaffolding preferred in construction?

Ringlock scaffolding is preferred due to its versatility, ease of assembly, high load capacity, and cost-effectiveness. It allows for quick setup and teardown, making it ideal for projects with tight deadlines.

Citations:

[1] https://www.ringlock.co.nz/main-components-of-ringlock-and-their-brief-descriptions/

[2] https://jumplyscaffolding.com/ringlock-scaffolding/

[3] https://www.zh-scaffolding.com/news/what-are-the-components-of-ringlock-scaffolding.html

[4] https://www.shutterstock.com/search/ring-lock-scaffold

[5] https://www.wm-scaffold.com/ring-lock-scaffold.html

[6] https://www.shutterstock.com/search/ring-lock-scaffolding?page=2

[7] https://www.ekscaffolding.com/ringlock-scaffolding.html

[8] https://www.pinterest.com/pin/ring-lock-scaffolding--705376360390039307/