Content Menu

● Understanding Climbing Scaffold Systems

>> Key Components

>> Types of Climbing Scaffold Systems

● Key Benefits of Climbing Scaffold Systems

>> Enhanced Safety

>> Increased Efficiency and Productivity

>> Cost-Effectiveness

>> Improved Quality and Precision

>> Versatility and Adaptability

>> Enhanced Project Management

● Conclusion

● FAQ

>> 1. What is a climbing scaffold system?

>> 2. How does a climbing scaffold system improve safety on construction sites?

>> 3. What types of construction projects are best suited for climbing scaffold systems?

>> 4. What are the key components of a climbing scaffold system?

>> 5. How does a climbing scaffold system contribute to cost savings?

● Citations:

The construction industry constantly seeks innovative solutions to enhance efficiency, safety, and cost-effectiveness. Among the groundbreaking advancements, the climbing scaffold system has emerged as a game-changer. Climbing scaffold systems, also known as self-climbing scaffolds or mast climbing work platforms, offer a myriad of benefits that address the common challenges faced in modern construction projects. This article explores the key advantages of using a climbing scaffold system, covering its components, safety features, cost savings, and applications, providing a comprehensive understanding of its impact on construction practices.

Understanding Climbing Scaffold Systems

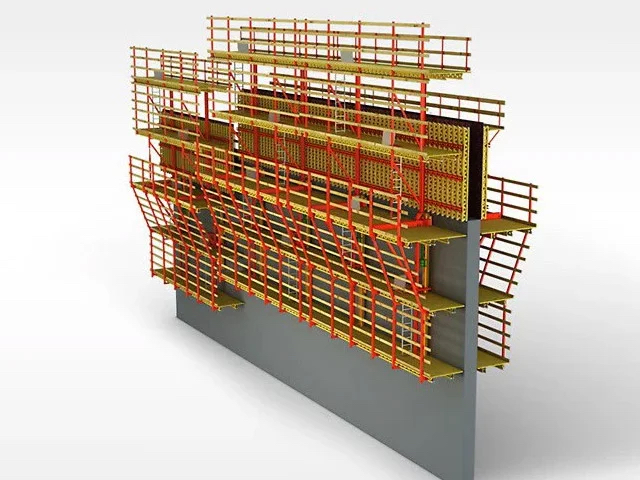

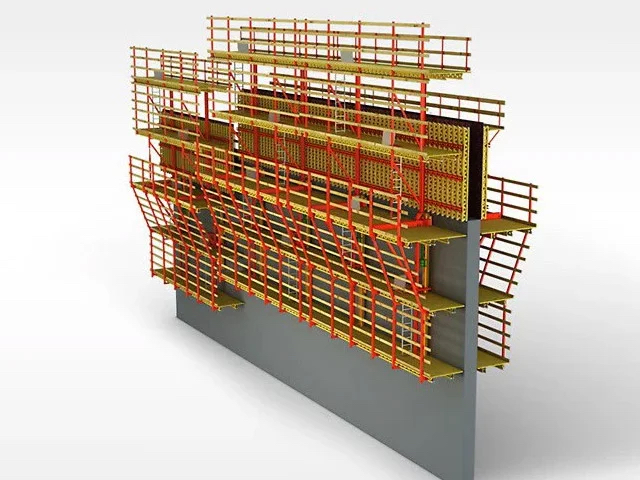

A climbing scaffold system is an automated scaffolding solution that uses hydraulic or electric mechanisms to ascend and descend along with the progress of construction [1, 9]. Unlike traditional scaffolding, which requires manual assembly and disassembly, a climbing scaffold system is designed to move vertically with minimal human intervention. This system typically consists of several key components working together to provide a safe and efficient working platform.

Key Components

Understanding the core components is essential for appreciating the functionality and benefits of a climbing scaffold system[1].

- Climbing Mechanism: This is the heart of the system, typically employing hydraulic cylinders or electric hoists to lift the scaffolding vertically[1].

- Anchoring System: The scaffolding is anchored to the building structure using specialized brackets and anchors, ensuring stability during climbing and operation[1].

- Working Platforms: These provide safe and spacious areas for workers to perform their tasks, often equipped with guardrails and toeboards for fall protection [1, 4].

- Formwork Integration (Optional): Some self-climbing systems integrate directly with formwork, allowing for simultaneous climbing and concrete pouring[1].

- Control System: A sophisticated control system manages the climbing process, ensuring synchronized movement and preventing overloads[1].

Types of Climbing Scaffold Systems

Climbing scaffold systems come in various types, each suited to different construction needs[1].

- Hydraulic Climbing Systems: These systems use hydraulic cylinders to lift the scaffold, offering high load capacity and precise control.

- Electric Hoist Systems: Electric hoists provide a more energy-efficient solution for lifting the scaffold, suitable for projects with moderate load requirements.

- Mast Climbing Work Platforms (MCWPs): These platforms use a mast system for vertical movement and are ideal for facade work, maintenance, and renovation projects [3, 5].

- Self-Climbing Formwork Systems: Integrated with formwork, these systems allow for simultaneous climbing and concrete pouring, accelerating the construction process.

Key Benefits of Climbing Scaffold Systems

The advantages of using a climbing scaffold system in construction are numerous, impacting safety, efficiency, cost, and overall project quality[1].

Enhanced Safety

Safety is a paramount concern in the construction industry, and climbing scaffold systems offer significant advantages in this regard[1].

- Reduced Risk of Falls: The system eliminates the need for workers to manually climb up and down scaffolding or ladders, reducing the risk of falls[1].

- Stable and Secure Platforms: Climbing scaffolds are generally much sturdier and more stable than traditional scaffolds[1].

- Protective Nets: They are also often equipped with protective nets to reduce the risk of falling objects that could result in serious workplace accidents[1].

- Form-Fit Connection: At all times, there is a form-fit connection between the scaffold and the structure[1].

- Three-Section Side Guard: This, in combination with the working levels secured by a three-section side guard or closed walls, reduces the risk to employees many times over[1].

- Intelligent Control System: The inclusion of a microcomputer intelligent control system further enhances safety measures by optimizing the operation of each self-climbing frame within the system[1].

- Overload Detection: This intelligent control system monitors lifting speed, weight loadings, and adherence to standardized design operations. It automatically detects any overloading or underloading issues, providing timely alerts for necessary safety actions, preventing potential dangers on-site[1].

- Guardrails: Scaffold guardrails serve the vital purpose of preventing workers from falling off open sides and ends of platforms [1, 4].

- Safe Climbing Practices: All scaffold users must adhere to designated climbing methods to prevent falls and injuries[6]. The only permissible ways to ascend and descend scaffolding are through ladders, ramps, or stair towers[6].

Increased Efficiency and Productivity

Climbing scaffold systems can significantly improve construction efficiency and productivity[1].

- Automatic Lifting: Automatic lifting to max within 30min, avoid setting up repeatedly[1].

- Faster Construction: Integrating climbing formworks speeds up the entire construction process, which, in turn, lowers the total production cost[1].

- Elimination of Cranes: Since it eliminates the need for cranes to reposition formwork, the process is faster and can often proceed in less time compared to traditional methods[1].

- Wider Work Area: By using either a crane-dependent or self-climbing scaffold system, your construction team will have more room to work and move around comfortably no matter how high off the ground they are[1].

- Versatility in Construction Projects: Mast climbers are incredibly versatile and can be used in a wide range of construction projects[5]. Whether it's for bricklaying, window installation, demolition, or façade maintenance, mast climbers provide a stable and adjustable platform[5].

- Better Access to Hard-to-Reach Areas: Mast climbers provide better access to hard-to-reach areas, making them ideal for complex architectural structures[5]. The adjustable platform allows workers to easily reach different parts of the building, ensuring that no area is left unattended[5].

Cost-Effectiveness

Although the initial investment in a self-climbing scaffolding system may be higher than traditional scaffolding, the long-term cost savings can be substantial[1].

- Reduced Labor Costs: The system eliminates the need for workers to manually climb up and down scaffolding or ladders, thus it can reduce the labor costs[1].

- Reduced Project Duration: Reduced project costs and duration[1].

- Less Labor Costs: Reduced construction time translates into lower labor costs and earlier project completion[1].

- Savings in Steel Material: Compared to conventional scaffolding system, applying GETO's self-climbing platform system to skyscrapers can help our clients to save 30% – 50% in cost (noted with 60% lower cost for steel material usage[1].

- Operational Cost Reduction: A 40% decrease in operational costs[1].

- Lower Electricity Consumption: An impressive 80% lower electricity consumption[1].

- Cost-Effectiveness: The increased efficiency and reduced installation costs make mast climbers a cost-effective solution for many construction projects[5].

- Flexible Installation: Unlike traditional scaffolding, which can be time-consuming and labor-intensive to set up, mast climbers can be assembled typically by less hands and in a much shorter time span allowing for your company to get to work quickly[5]. This not only saves time but also reduces labor costs, making the construction process more efficient[5].

- Mast climbing work platforms help optimize construction costs by reducing energy consumption and maintenance costs[3].

Improved Quality and Precision

Climbing scaffold systems offer improved quality and precision in construction[1].

- Precision of the self-climbing system: This ensures high-quality concrete finishes and consistent structural integrity[1].

- High Quality Concrete Finishes: This precision reduces the likelihood of errors and rework[1].

Versatility and Adaptability

Climbing scaffold systems are versatile and adaptable to various construction needs[1].

- Weather Independence: Self-climbing formwork is less affected by weather conditions since the formwork and work platforms are integral and move together, offering better protection for workers and materials[1].

- Suitable for Various Structures: Self-climbing formwork is ideal for high-rise buildings, skyscrapers, bridges, silos, and other tall structures[1].

- Repetitive Elements: Structures with repeated floor plans or identical vertical elements benefit from the repetitive efficiency of self-climbing formwork[1].

- Flexibility in Weather Conditions: Mast climbers offer flexibility in various weather conditions, making them a reliable choice for construction projects[5].

- Space-Saving Design: The compact design of mast climbers makes them an excellent choice for construction sites with limited space or a smaller footprint[5].

Enhanced Project Management

- Enhanced Project Management: Using mast climbers can enhance overall project management by providing better control over the construction process[5]. The ease of assembly and disassembly, combined with the increased efficiency and safety, allows project managers to streamline operations[5]. This leads to better coordination, reduced downtime, and ultimately, successful project completion[5].

Conclusion

Climbing scaffold systems represent a significant advancement in construction technology, offering a multitude of benefits that enhance safety, efficiency, cost-effectiveness, and overall project quality. By understanding the components, types, and advantages of these systems, construction professionals can make informed decisions about their implementation. Embracing climbing scaffold systems not only improves working conditions and productivity but also contributes to the successful and timely completion of construction projects.

FAQ

1. What is a climbing scaffold system?

A climbing scaffold system is an automated scaffolding solution that uses hydraulic or electric mechanisms to ascend and descend along with the progress of construction [1, 9]. It provides a safe and efficient working platform, eliminating the need for manual assembly and disassembly.

2. How does a climbing scaffold system improve safety on construction sites?

It reduces the risk of falls, provides stable and secure platforms, incorporates protective nets, and often includes intelligent control systems with overload detection[1].

3. What types of construction projects are best suited for climbing scaffold systems?

While versatile, climbing scaffolding systems are best suited for high-rise buildings, skyscrapers, bridges, silos, and other tall structures with repetitive elements [1, 7].

4. What are the key components of a climbing scaffold system?

Key components include the climbing mechanism, anchoring system, working platforms, and often formwork integration and a sophisticated control system[1].

5. How does a climbing scaffold system contribute to cost savings?

It reduces labor costs, shortens project duration, saves on steel material usage, lowers electricity consumption, and enhances overall operational efficiency[1].

Citations:

[1] https://www.tp-scaffold.com/what-are-the-key-benefits-of-a-self-climbing-scaffolding-system.html

[2] https://www.ucop.edu/safety-and-loss-prevention/_files/perform-arts/fp-scaffold.pdf

[3] https://maksanlift.com/en/advantages-of-mast-climbing-work-platforms-over-scaffolding/

[4] https://scaffold.com/13-safety-features-designed-into-modern-construction-scaffolds/

[5] https://www.actionscaffold.com/post/rise-above-the-rest-with-mast-climbers-unveiling-their-hidden-benefits

[6] https://www.scaffoldingsolutions.com/articles/11-scaffolding-safety-tips/

[7] https://www.ihsa.ca/rtf/health_safety_manual/pdfs/equipment/Scaffolds.pdf

[8] https://www.ccohs.ca/oshanswers/safety_haz/platforms/scaffolduse.html