Content Menu

● Understanding Moving Scaffolding Systems

● Key Benefits of Moving Scaffolding Systems

● Main Features of a Reliable Moving Scaffolding System

● 1. Sturdy and Durable Construction

● 2. Adjustable Height

● 3. Lockable Wheels or Casters

● 4. Safety Features

● 5. Modular Design

● Applications of Moving Scaffolding Systems

● How to Choose the Best Moving Scaffolding System

● Conclusion

● FAQ

>> 1. What is the maximum height a moving scaffolding system can reach?

>> 2. How do I maintain my moving scaffolding system?

>> 3. Are moving scaffolding systems safe for outdoor use?

>> 4. Can I assemble a moving scaffolding system by myself?

>> 5. What materials are best for moving scaffolding systems?

● Citations:

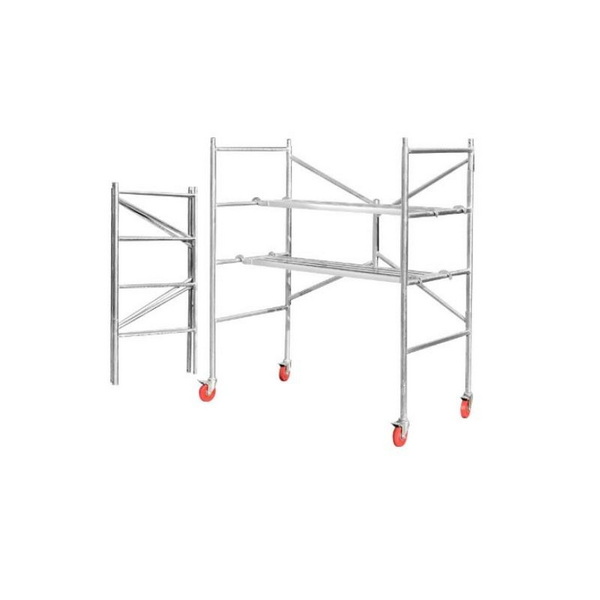

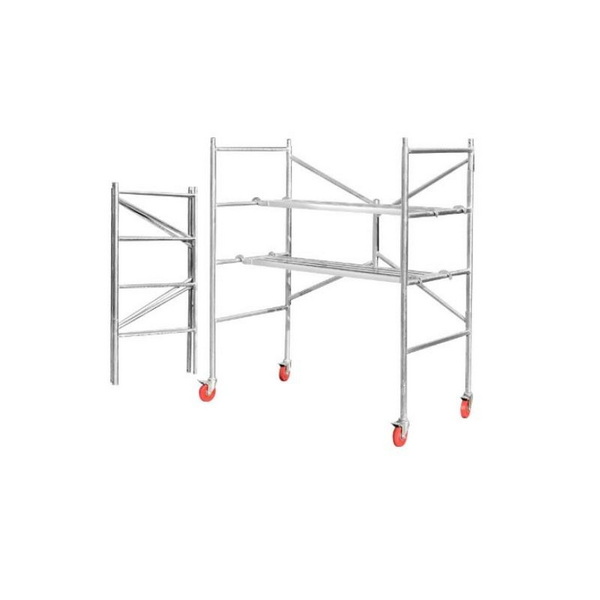

Moving scaffolding systems are essential tools in construction, renovation, and maintenance projects. Their ability to provide mobility, flexibility, and safety makes them indispensable for workers operating at heights. But what makes a moving scaffolding system reliable? In this article, we will explore the main features of a dependable moving scaffolding system, supported by visuals and videos to enhance understanding.

Understanding Moving Scaffolding Systems

A moving scaffolding system is a type of scaffold equipped with wheels or casters that allow it to be easily moved from one location to another. These systems are widely used in construction sites, warehouses, and industrial facilities due to their versatility.

Key Benefits of Moving Scaffolding Systems

- Mobility: Easy to relocate without dismantling.

- Efficiency: Reduces downtime during project transitions.

- Safety: Equipped with brakes and stabilizers for secure positioning.

- Cost-Effective: Reusable and reduces the need for multiple setups.

Main Features of a Reliable Moving Scaffolding System

1. Sturdy and Durable Construction

A reliable moving scaffolding system is made from high-quality materials such as aluminum or steel. These materials ensure durability while maintaining a lightweight structure for easy mobility.

- Aluminum: Lightweight and resistant to corrosion.

- Steel: Offers superior strength for heavy-duty applications.

2. Adjustable Height

Adjustable height is a critical feature that allows the scaffold to cater to various project requirements. Reliable systems come with easy-to-operate mechanisms for height adjustments.

3. Lockable Wheels or Casters

The wheels or casters in a moving scaffolding system should have locking mechanisms to ensure stability when the scaffold is stationary. This feature prevents unwanted movement during use.

4. Safety Features

Safety is paramount in any scaffolding system. Key safety features include:

- Guardrails to prevent falls.

- Non-slip platforms for secure footing.

- Stabilizing outriggers for added balance.

5. Modular Design

A modular design allows for easy assembly, disassembly, and customization. It ensures that the scaffold can be adapted to different project needs without requiring specialized tools.

Applications of Moving Scaffolding Systems

Moving scaffolding systems are versatile and can be used in various industries:

1. Construction: For painting, plastering, and repairs.

2. Warehousing: For accessing high shelves.

3. Industrial Maintenance: For equipment servicing at elevated heights.

4. Event Setup: For installing lighting or decorations.

How to Choose the Best Moving Scaffolding System

When selecting a moving scaffolding system, consider the following factors:

1. Load Capacity: Ensure it can support the weight of workers and tools.

2. Ease of Mobility: Check the quality of wheels and their locking mechanisms.

3. Compliance with Standards: Verify that it meets safety regulations such as OSHA or EN standards.

4. Budget-Friendly Options: Balance cost with quality and features.

Conclusion

A reliable moving scaffolding system combines durability, safety, and flexibility to meet diverse project requirements. By investing in a high-quality system, you ensure worker safety, enhance efficiency, and achieve better project outcomes.

FAQ

1. What is the maximum height a moving scaffolding system can reach?

Most moving scaffolding systems can reach heights of up to 20 feet or more, depending on their design and specifications.

2. How do I maintain my moving scaffolding system?

Regularly inspect for wear and tear, clean the components after use, lubricate movable parts, and store it in a dry place to prevent corrosion.

3. Are moving scaffolding systems safe for outdoor use?

Yes, but ensure they are equipped with stabilizers or outriggers to withstand wind conditions during outdoor use.

4. Can I assemble a moving scaffolding system by myself?

Most systems come with user-friendly instructions for assembly; however, having an additional person can make the process safer and quicker.

5. What materials are best for moving scaffolding systems?

Aluminum is ideal for lightweight applications, while steel is better suited for heavy-duty tasks due to its strength.

Citations:

[1] https://pplx-res.cloudinary.com/image/upload/v1738771057/user_uploads/ffzGMYtTzBOZiUq/image.jpg