Content Menu

● 1. Introduction to System Scaffolding

● 2. Key Components of System Scaffold Parts

● 3. Detailed Description of Each Scaffold Part

>> Base Plates

>> Standards (Uprights)

>> Ledgers

>> Transoms

>> Braces

>> Platforms (Decks)

>> Guardrails

>> Toeboards

● 4. Importance of Proper Assembly and Maintenance

● 5. Best Practices for Scaffold Use

● 6. Conclusion

● FAQ

>> 1. What is system scaffolding?

>> 2. Why are base plates important in scaffolding?

>> 3. How do braces contribute to scaffold safety?

>> 4. What materials are commonly used for scaffold platforms?

>> 5. How often should scaffolds be inspected?

In the construction industry, scaffolding is an essential component that provides temporary support and access to various parts of a building during construction, maintenance, or repair. Understanding the different system scaffold parts is crucial for ensuring safety, efficiency, and stability on construction sites. This article delves into the most important scaffold components, their functions, and the role they play in construction projects.

1. Introduction to System Scaffolding

System scaffolding refers to a modular framework used to support workers and materials during construction activities. Unlike traditional scaffolding, which may require custom assembly for each project, system scaffolding is designed with standardized components that can be easily assembled and disassembled. This not only enhances safety but also improves efficiency on job sites.

The use of system scaffolding has gained popularity due to its versatility and adaptability across various types of construction projects. It can be used in residential, commercial, and industrial settings, making it a go-to solution for many contractors.

2. Key Components of System Scaffold Parts

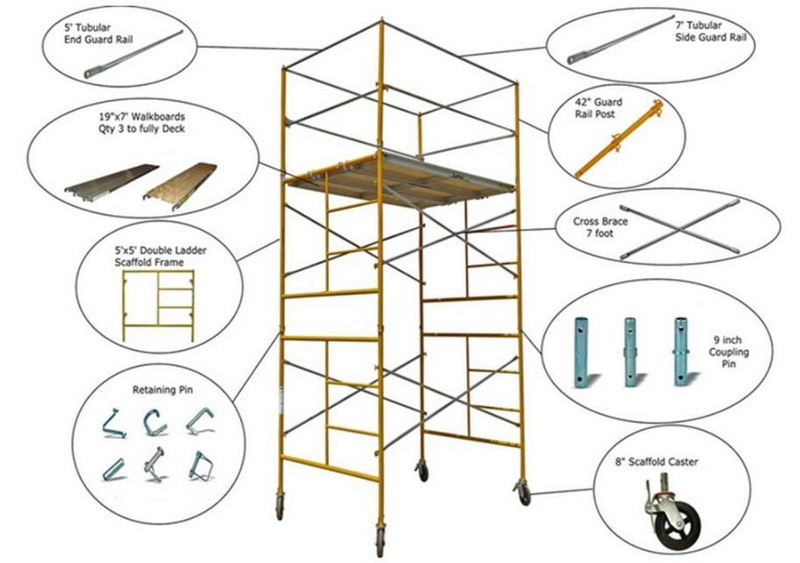

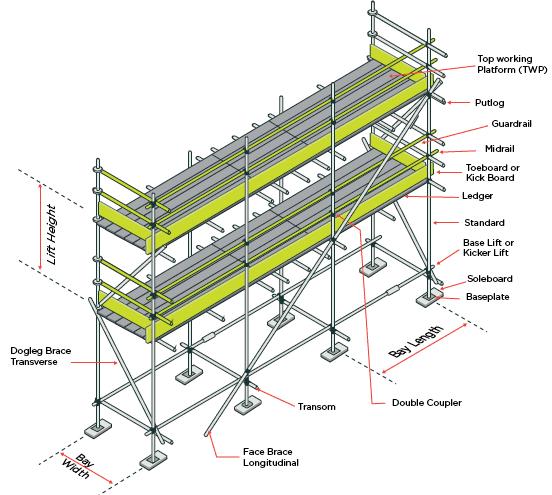

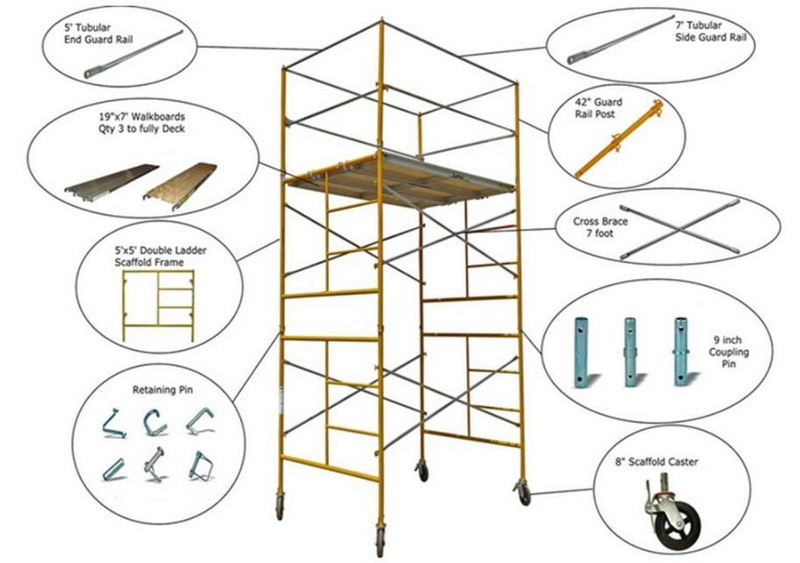

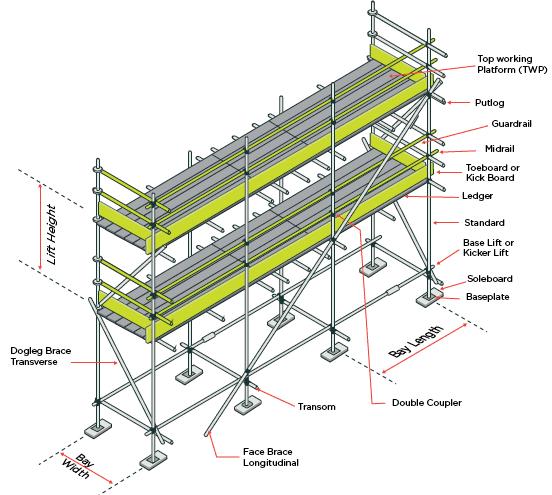

Understanding the various parts of a scaffold system is essential for anyone involved in construction. Below are the primary components that make up a typical system scaffold:

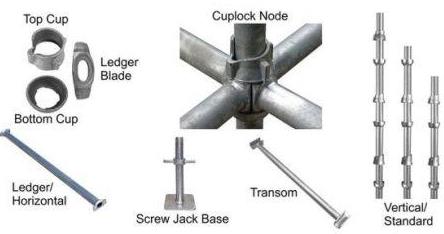

- Base Plates: These are flat plates placed at the bottom of vertical standards to distribute the weight of the scaffold evenly across the ground. They prevent sinking into soft soil and enhance stability.

- Standards (Uprights): Vertical tubes that form the main framework of the scaffold. They bear the load and provide vertical support.

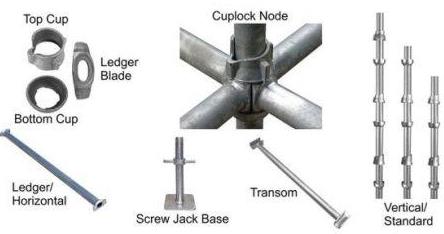

- Ledgers: Horizontal tubes that connect standards together, providing lateral support and helping to distribute loads evenly across the structure.

- Transoms: These are horizontal members placed at right angles to ledgers. They support working platforms and increase the load-bearing capacity of the scaffold.

- Braces: Diagonal supports that reinforce the structure's rigidity and prevent swaying or collapsing. They are critical for maintaining stability under external forces like wind.

- Platforms (Decks): Flat surfaces where workers stand or place materials. These can be made from wood or composite materials.

- Guardrails: Safety features installed at working levels to prevent falls. They are typically placed parallel to ledgers.

- Toeboards: Protective barriers placed near walking surfaces to prevent tools or materials from falling off.

3. Detailed Description of Each Scaffold Part

Base Plates

Base plates are crucial for providing a stable foundation for scaffolds. They help distribute weight over a larger area, reducing the risk of ground subsidence. Typically made from steel, base plates are designed to withstand heavy loads and ensure that standards remain upright.

Base plates come in various sizes depending on the type of scaffold being used and the load it needs to support. Some advanced designs include adjustable base plates that allow for leveling on uneven ground, enhancing safety further.

Standards (Uprights)

Standards are vertical components that provide primary support for the scaffold structure. They are usually connected to base plates at their bottom and extend upwards to connect with ledgers and transoms. The height of standards determines how high the scaffold can be built.

Standards must be made from high-strength materials such as steel or aluminum to ensure they can handle significant loads without bending or breaking. Regular inspections should be conducted to check for any signs of wear or damage.

Ledgers

Ledgers run horizontally between standards, offering structural integrity by connecting uprights and providing lateral support. They play a vital role in maintaining the overall stability of the scaffold system by preventing lateral movement.

Ledgers are available in different lengths depending on the specific requirements of a project. Proper installation is critical; they must be securely fastened to prevent any shifting during use.

Transoms

Transoms are essential for creating a stable working platform by supporting planks or boards where workers stand. They also help distribute loads across ledgers, ensuring even weight distribution.

Transoms can be fixed or adjustable, allowing for flexibility in design based on project needs. Their placement is crucial; they must align properly with both ledgers and platforms to ensure safety.

Braces

Braces are diagonal members that add rigidity to the scaffold structure. By connecting standards and ledgers, they prevent twisting and swaying due to wind or other external forces, making them vital for safety.

Braces must be installed at appropriate angles—usually 45 degrees—to maximize their effectiveness in stabilizing the scaffold structure. Regular checks should ensure they remain securely fastened throughout the project duration.

Platforms (Decks)

Platforms provide a safe working area for construction workers. They can be made from various materials but must meet safety standards to ensure they can support both workers and materials without risk of collapse.

Platforms should be designed with non-slip surfaces to reduce accidents caused by slipping while working at heights. Additionally, they should be regularly inspected for any signs of wear or damage.

Guardrails

Guardrails are installed at various heights on scaffolds to protect workers from falling off edges. They are an essential safety feature that helps maintain a secure working environment.

The installation height of guardrails typically follows safety regulations which may vary by region but generally requires guardrails at least 39 inches above walking surfaces. Properly installed guardrails significantly reduce fall-related injuries on construction sites.

Toeboards

Toeboards serve as an additional safety measure by preventing tools and materials from falling off the edge of platforms, protecting workers below from potential injuries.

Toeboards should be at least 4 inches high and securely fastened along platform edges to ensure they effectively contain any dropped items during work activities.

4. Importance of Proper Assembly and Maintenance

The effectiveness of system scaffolding relies heavily on proper assembly and maintenance:

- Assembly: Each component must be correctly installed according to manufacturer specifications and safety regulations. This ensures stability and reduces risks associated with improper setups.

- Maintenance: Regular inspections should be conducted to check for wear and tear on components such as base plates, standards, guardrails, and platforms. Any damaged parts should be replaced immediately to maintain safety standards.

Proper training for workers involved in assembling scaffolds is also essential; they must understand how each component interacts within the system to ensure maximum safety during operations.

5. Best Practices for Scaffold Use

To maximize safety while using scaffolds on construction sites:

- Always conduct a thorough inspection before use.

- Ensure all components are compatible with one another.

- Maintain clear communication among team members regarding scaffold use.

- Use personal protective equipment (PPE) such as helmets and harnesses when working at heights.

- Follow all local regulations regarding scaffold installation and use.

- Keep work areas organized to minimize hazards related to falling tools or materials.

6. Conclusion

In conclusion, understanding the various system scaffold parts is vital for anyone involved in construction projects. Each component plays a specific role in ensuring safety, stability, and efficiency on job sites. By adhering to proper assembly techniques and conducting regular maintenance checks, construction professionals can significantly reduce risks associated with scaffolding use while enhancing productivity on-site.

FAQ

1. What is system scaffolding?

System scaffolding is a modular framework used in construction that consists of standardized components designed for easy assembly and disassembly while providing safe access and support during building activities.

2. Why are base plates important in scaffolding?

Base plates distribute the weight of the scaffold evenly across the ground, preventing sinking into soft soil and enhancing overall stability.

3. How do braces contribute to scaffold safety?

Braces provide diagonal support that reinforces the structure's rigidity, preventing swaying or collapsing under external forces like wind or heavy loads.

4. What materials are commonly used for scaffold platforms?

Platforms can be made from various materials including wood, metal, or composite materials designed to support workers safely during construction activities.

5. How often should scaffolds be inspected?

Scaffolds should be inspected regularly—ideally before each use—to check for any signs of damage or wear on components such as base plates, standards, guardrails, and platforms.