Content Menu

● Understanding a Scaffolding Pump Jack System

● Essential Safety Guidelines

>> 1. Pre-Setup Inspection and Planning

>> 2. Safe Setup Procedures

>> 3. Safe Operational Practices

>> 4. Safe Dismantling Procedures

● Regulatory Compliance

● Training and Hazard Recognition

● Conclusion

● FAQ

>> 1. What are the primary hazards associated with scaffolding pump jack systems?

>> 2. How often should a scaffolding pump jack system be inspected?

>> 3. What type of fall protection is required when using a scaffolding pump jack system?

>> 4. Can a pump jack system be used on any type of surface?

>> 5. What should I do if I identify a damaged component on a pump jack system?

● Citations:

A scaffolding pump jack system is a highly efficient and versatile method for elevating workers and materials on a construction site, particularly for tasks like siding, painting, roofing, and other exterior work[2]. However, the very nature of working at height introduces significant risks, making strict adherence to safety guidelines absolutely essential. This article outlines the key safety considerations for the setup, operation, and dismantling of a scaffolding pump jack system, aiming to provide a comprehensive resource for both experienced professionals and DIY users.

Understanding a Scaffolding Pump Jack System

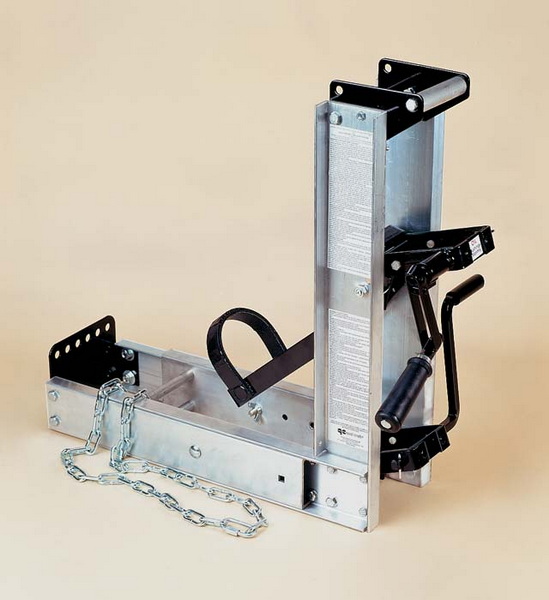

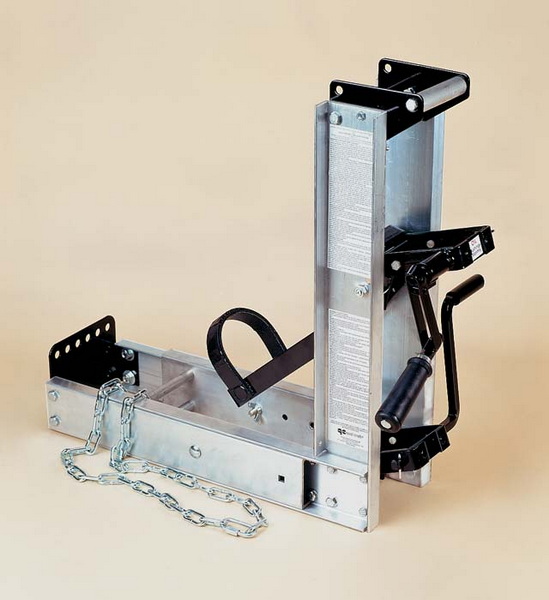

Before delving into the safety guidelines, it's crucial to understand the basic components of a scaffolding pump jack system[2]:

- Vertical Poles: These are typically made of aluminum or wood and provide the main vertical support for the system[2]. Aluminum poles are often preferred for their durability and consistent quality[2].

- Pump Jack Brackets: These movable brackets attach to the poles and support the work platform. They incorporate a pumping mechanism that allows users to raise and lower the platform[2].

- Work Platform: Usually constructed from planks, this provides the working surface for personnel and materials[2].

- Brace Supports: These are essential for stabilizing the poles and preventing them from swaying or buckling[2].

- Safety Rails & Toeboards: Guardrails and toeboards that must be installed on all sides where a fall hazard is present[1].

- Base Plates/Mud Sills: Used to provide a stable footing for the poles, especially on uneven or soft ground[1].

Essential Safety Guidelines

The following guidelines encompass critical safety practices for every stage of pump jack scaffolding system operation.

1. Pre-Setup Inspection and Planning

- Competent Person Supervision: All erection, moving, alteration, or dismantling of the scaffolding pump jack system must be supervised and directed by a competent person qualified in scaffold construction[1].

- Trained Employees: Only experienced and trained employees selected by the competent person should perform the work[1].

- Manufacturer's Instructions: Always erect, operate, and maintain the pump jack system in strict accordance with the manufacturer's instructions. Keep a copy of these instructions readily available on-site[1][4].

- Component Inspection: Thoroughly inspect all scaffolding components for damage before each use. Do not use bent, cracked, damaged, or substitute parts[1].

- Ground Conditions: Ensure the poles are placed on mud sills or another adequate firm foundation to prevent sinking or instability[1].

- Load Limits: Never exceed the maximum allowable safe working load, which is often around 500 pounds[1]. Limit the number of workers on the platform to a maximum of two between supporting poles[1][9]. Loads on a pumpjack scaffold should be less than 122 kg per square metre or 25 lbs per square foot[9].

2. Safe Setup Procedures

- Pole Spacing: Position the poles at the correct distance apart based on project needs and platform length[2].

- Pole Integrity: If using wooden poles, ensure they are straight and structurally sound. Aluminum poles should be free of dents or damage[2].

- Secure Pole Attachment: Secure each pole firmly using base plates or by burying them according to manufacturer specifications[2].

- Bracket Engagement: Slide the pump jack brackets onto the poles, ensuring they are properly engaged and functioning smoothly[2].

- Platform Security: Place scaffolding planks between the brackets, ensuring they are level and secure. Overlap planks according to OSHA requirements if using multiple planks[2].

- Guardrails and Toeboards: Install guardrails and toeboards for additional safety on all open sides where fall hazard is present[2][1]. A bench platform, incorporated in the scaffold at an approximate height of 42 inches, is acceptable in lieu of a top rail. A mid-rail must be installed in all cases[1].

- Bracing Installation: Install bracing at least every 4.6 meters (approximately 15 feet), starting from the base of the scaffold[4][9]. Additional bracing may be required per the manufacturer's specifications[4]. Braces must be secured to the pole and fastened to the structure of the building with four brace screws per brace[8].

- Vertical Alignment: Support poles and work platforms must be level and plumb[4].

3. Safe Operational Practices

- Fall Protection: Employees working on a scaffold more than 10 feet (3.1 m) above a lower level must use a personal fall arrest system or guardrails[1].

- Safe Climbing: When raising the pump jack scaffolding system place your foot in the stirrup of the pump jack and engage slowly until you are raised approximately one foot[8]. Repeat this procedure with the other pump jacks if two people are operating, then both pump checks may be engaged for raising at the same time[8]. Always keep the work surface level and secure the jack by placing the stirrup in the up position[8][10].

- Level Platform: Always keep the work surface level[8].

- Passing Braces: Passing a brace is accomplished by first securing an extra brace approximately four feet above the one to be passed until the brace is reinstalled[8].

- Lowering the System: Face the pole and raise the stirrup to the up position, ensure that the crank handle is in the locked position holding on to the pole place one foot on the pedal of the lower brake press down and hold open, take hold of the crank handle pulling the arm out to the right[8].

4. Safe Dismantling Procedures

- Follow the setup steps in reverse order, ensuring stability at each stage.

- Never remove bracing until the structure above is adequately supported.

- Lower components carefully; never drop or throw anything from the scaffold.

Regulatory Compliance

- OSHA Standards: Adhere to all applicable OSHA (Occupational Safety and Health Administration) regulations regarding scaffolding safety.

- ANSI Standards: Comply with relevant ANSI (American National Standards Institute) standards.

- Local Codes: Check and adhere to all applicable state and local codes for specific requirements[7].

Training and Hazard Recognition

- Hazard Recognition Training: Employers must provide training for workers in hazard recognition and procedures for controlling or minimizing hazards when working on ladders and scaffolding[1].

- Regular Safety Meetings: Conduct regular safety meetings to reinforce safe practices and address any emerging concerns.

Conclusion

Operating a scaffolding pump jack system safely requires a combination of proper planning, thorough inspection, adherence to manufacturer's guidelines, and consistent use of safe work practices. By following the guidelines outlined in this article and prioritizing safety at every stage, construction professionals and DIY users can significantly reduce the risk of accidents and ensure a safe working environment. Regular training, diligent inspections, and a commitment to safety are crucial for preventing injuries and ensuring the well-being of all workers using scaffolding pump jack systems.

FAQ

1. What are the primary hazards associated with scaffolding pump jack systems?

The primary hazards include falls from height, scaffold collapse due to overloading or improper setup, electrocution from contact with power lines, and being struck by falling objects.

2. How often should a scaffolding pump jack system be inspected?

A scaffolding pump jack system should be inspected before each shift and after any event that could affect its integrity, such as strong winds or heavy impact.[1]

3. What type of fall protection is required when using a scaffolding pump jack system?

When working more than 10 feet above a lower level, employees must use a personal fall arrest system or guardrails. Safety codes require guard rails and toe boards on all open sides when scaffold platform height is 10 feet or more, and may be required at lower heights, depending on the application and jurisdiction[1][7].

4. Can a pump jack system be used on any type of surface?

Pump jack systems can be used on various surfaces, but the ground must be firm and stable. Use mud sills or base plates to distribute the load and prevent the poles from sinking, especially on soft ground[1].

5. What should I do if I identify a damaged component on a pump jack system?

Immediately remove the damaged component from service and replace it with a new, approved part. Never attempt to repair a damaged component, and do not use substitute parts[1].

Citations:

[1] https://www.pitb.com/pump-jack-scaffolding-requirements/

[2] https://scaffoldingrentalandsales.com/blog/-how-to-properly-set-up-and-dismantle-a-pump-jack-system/

[3] https://www.youtube.com/watch?v=Ac3L_7W0gbY

[4] https://novascotia.ca/lae/healthandsafety/docs/safety-bulletin-0000024-en.pdf

[5] https://falconladder.com/content/PUMPJACK/Pump-Jack-System-Instructions.pdf

[6] https://www.youtube.com/watch?v=cwH-3iXREhk

[7] https://www.badgerladder.com/pdfs/titan-safety-instructions.pdf

[8] https://www.youtube.com/watch?v=BUAO-ZQYZ_k

[9] https://ppwg.ccohs.ca/topic/scaffolding/

[10] https://images.thdstatic.com/catalog/pdfImages/01/012d6c7e-30c0-4690-b60e-170259e30fdf.pdf