Content Menu

● Introduction to A Frame Scaffolding

● Tube Specifications

● Standard A Frame Scaffolding Dimensions

● Common Models

● A Frame Scaffolding in Different Regions

>> Asia and Australia

>> North America

>> Europe

● Safety Considerations

>> Compliance with Standards

>> Best Practices for Assembly

● Customization and Accessories

● Environmental Considerations

● Sustainable Practices

● Conclusion

● FAQ

>> 1. What are the typical materials used for A frame scaffolding?

>> 2. What are the standard dimensions for A frame scaffolding in Australia?

>> 3. How does A frame scaffolding comply with safety standards?

>> 4. What are the advantages of using A frame scaffolding?

>> 5. Can A frame scaffolding be customized for specific projects?

● Citations:

A frame scaffolding is a widely used scaffolding system in construction and maintenance projects due to its simplicity, durability, and ease of assembly. It consists of two vertical frames connected by horizontal bars, forming an "A" shape. This design provides excellent stability and support for workers and materials. Understanding the standard dimensions of A frame scaffolding is crucial for ensuring safety and efficiency on job sites.

Introduction to A Frame Scaffolding

A frame scaffolding is fabricated from steel tubes, typically with a galvanized finish to enhance durability and resistance to corrosion. The frames are often made from steel grade Q235, which offers a good balance between strength and cost-effectiveness. The tube specifications for A frame scaffolding can vary, but common dimensions include an outside diameter (OD) of 48.3 mm for the frame legs and 27 mm for handrails and cross braces.

Tube Specifications

- Frame Leg OD: 48.3 mm

- Handrail and Cross Brace OD: 27 mm

- Wall Thickness: Typically 3.25 mm or 3.0 mm for frame legs and 2.3 mm for handrails and cross braces.

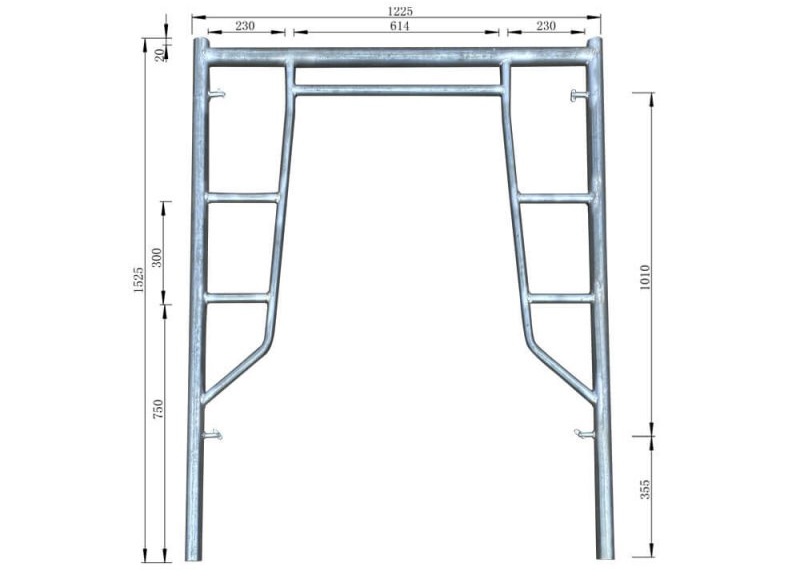

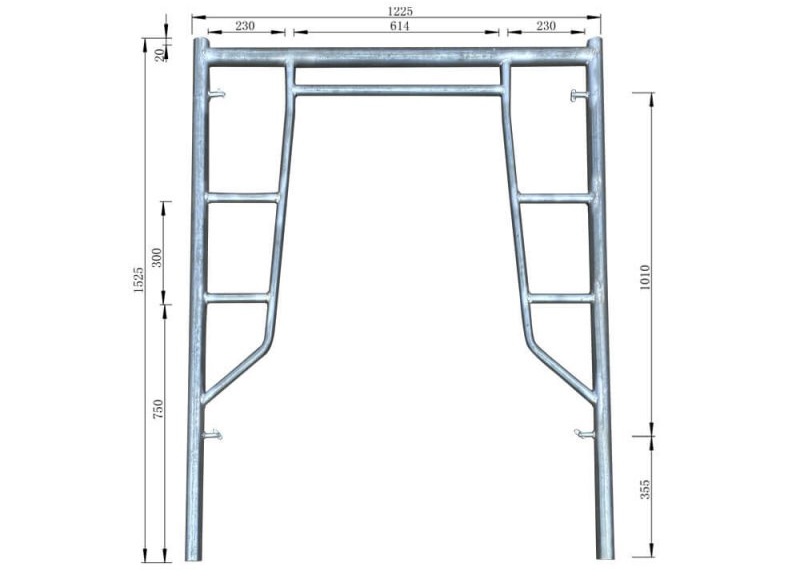

Standard A Frame Scaffolding Dimensions

Standard A frame scaffolding dimensions can vary depending on the manufacturer and region. However, common dimensions include:

- Width: 1310 mm (standard) and 780 mm (narrow)

- Height: Ranges from 1525 mm to 2000 mm

- Lock Space: Typically 1010 mm.

Common Models

Some common models of A frame scaffolding include:

| Code | Description | Width (W) | Height (H) | Lock Space (A) | Weight (kg) |

| AUF.S20 | Standard Frame 1310x2000mm | 1312 mm | 2000 mm | 1010 mm | 26.10 kg |

| AUF.N20 | Narrow Frame 780x2000mm | 780 mm | 2000 mm | 1010 mm | 23.10 kg |

| AUF.S18 | Standard Frame 1310x1825mm | 1312 mm | 1825 mm | 1010 mm | 24.70 kg |

| AUF.N18 | Narrow Frame 780x1825mm | 780 mm | 1825 mm | 1010 mm | 21.70 kg |

A Frame Scaffolding in Different Regions

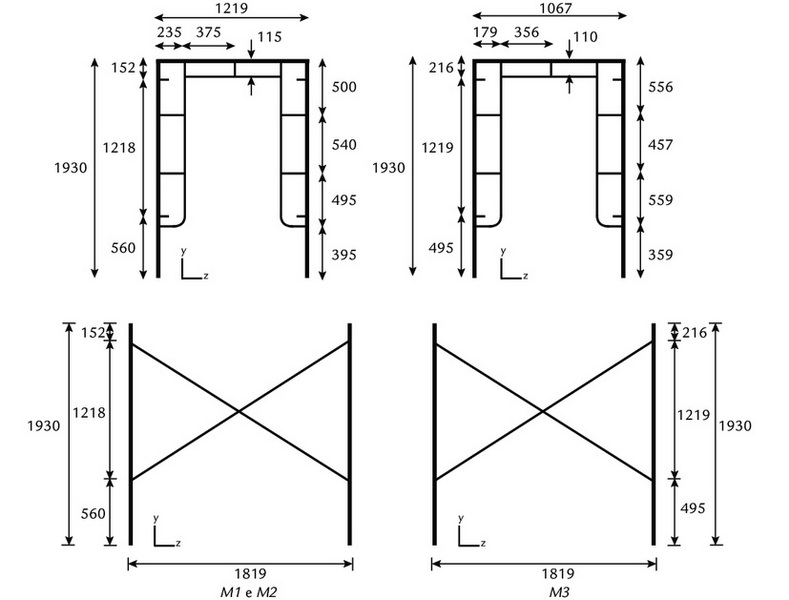

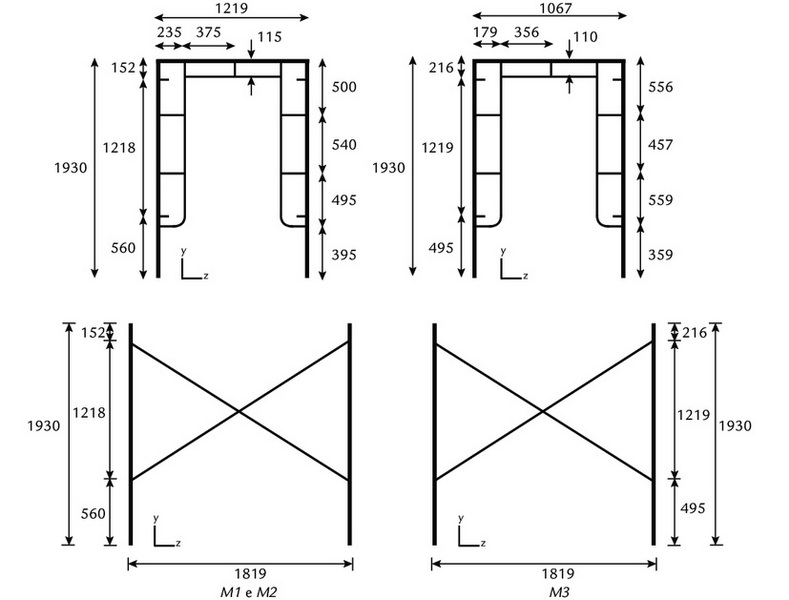

A frame scaffolding is used globally, with variations in dimensions and materials based on local standards and preferences.

Asia and Australia

In Asia and Australia, A frame scaffolding is widely used for its ease of assembly and durability. For example, in Malaysia, the BW A Frame Scaffolding system is popular, with dimensions of 1219 mm width and 1700 mm height.

North America

In North America, scaffolding frames often comply with OSHA and ANSI standards. Common sizes include 5-foot wide frames, which are suitable for general maintenance and construction projects.

Europe

In Europe, scaffolding must comply with EN 1004 standards, which specify requirements for scaffolding design, testing, and safety. European manufacturers often provide customized solutions to meet specific project needs.

Safety Considerations

Safety is paramount when using A frame scaffolding. Ensuring that the scaffolding is properly assembled and secured is crucial to prevent accidents. Regular inspections and adherence to local safety standards are also essential.

Compliance with Standards

A frame scaffolding must comply with local safety standards, such as OSHA in the U.S. and MS1462:1999 in Malaysia.

Best Practices for Assembly

1. Ensure Proper Foundation: The scaffolding should be placed on a firm, level surface.

2. Use Correct Couplers: Use the correct type and number of couplers to secure the frames together.

3. Regular Inspections: Conduct regular inspections to ensure all components are secure and undamaged.

Customization and Accessories

A frame scaffolding can be customized with various accessories to enhance functionality and safety. Common accessories include:

- Stairways: Provide safe access to higher levels.

- Guardrails: Prevent falls from the scaffolding platform.

- Toeboards: Protect workers from falling objects.

Environmental Considerations

A frame scaffolding is generally environmentally friendly due to its durability and reusability. However, proper disposal of damaged components is important to minimize environmental impact.

Sustainable Practices

1. Reuse Components: Reuse scaffolding components whenever possible.

2. Recycle Materials: Recycle metal components at the end of their life cycle.

3. Minimize Waste: Ensure all packaging and waste materials are disposed of responsibly.

Conclusion

A frame scaffolding dimensions can vary based on the intended use, region, and manufacturer. Understanding these dimensions is crucial for ensuring safety and efficiency on construction sites. Whether in Asia, Australia, or North America, A frame scaffolding remains a versatile and reliable choice for scaffolding needs.

FAQ

1. What are the typical materials used for A frame scaffolding?

A frame scaffolding is typically made from steel, often with a galvanized finish to enhance durability and resistance to corrosion. The steel grade used is usually Q235, which offers a good balance between strength and cost-effectiveness.

2. What are the standard dimensions for A frame scaffolding in Australia?

In Australia, standard A frame scaffolding dimensions include widths of 1310 mm (standard) and 780 mm (narrow), with heights ranging from 1525 mm to 2000 mm.

3. How does A frame scaffolding comply with safety standards?

A frame scaffolding must comply with local safety standards. For example, in the U.S., it must meet or exceed OSHA and ANSI specifications, while in Malaysia, it complies with MS1462:1999.

4. What are the advantages of using A frame scaffolding?

A frame scaffolding offers several advantages, including ease of assembly, durability, and cost-effectiveness. It is also versatile and can be used in various construction and maintenance projects.

5. Can A frame scaffolding be customized for specific projects?

Yes, A frame scaffolding can be customized to meet specific project requirements. Manufacturers often provide options for different frame sizes, coatings, and accessories to suit various needs.

Citations:

[1] https://www.gzshuangma.com/as-nzs-australian-a-frame-scaffolding_p44.html

[2] https://www.gettyimages.in/videos/scaffolding-frames

[3] https://www.bclts.org.uk/onewebmedia/Applied%20Chinese%20Language%20Studies%20IV.pdf

[4] https://www.graniteind.com/standard-scaffold-frames/

[5] https://www.istockphoto.com/photos/frame-scaffolding

[6] https://github.com/Genghao-025/StarrySky/blob/master/README.md

[7] https://lynnladder.com/product/5-foot-wide-standard-scaffold-frames/

[8] https://www.youtube.com/watch?v=ZYzbjPRzI6Q

[9] https://builtory.my/products/BW-A-Frame-Scaffolding?id=K602