Content Menu

● What Is the Cuplock Scaffolding System?

● Core Components and Their Specifications

>> 1. Cuplock Standards (Verticals)

>> 2. Cuplock Ledgers (Horizontals)

>> 3. Cuplock Braces (Swivel Braces)

>> 4. Other Accessories

● Material and Manufacturing Standards

● Load Capacities and Structural Strength

>> Vertical Load (Leg Capacity)

>> Horizontal Load

>> Safety Factors

● Assembly and Locking Mechanism

● Advantages of the Cuplock System

● Typical Applications

● Conclusion

● FAQ

>> 1. What are the standard dimensions of cuplock scaffolding standards?

>> 2. How often are the locking cups welded on the standards?

>> 3. What materials are used for cuplock scaffolding components?

>> 4. How much load can a cuplock standard support?

>> 5. Is the cuplock system compliant with international safety standards?

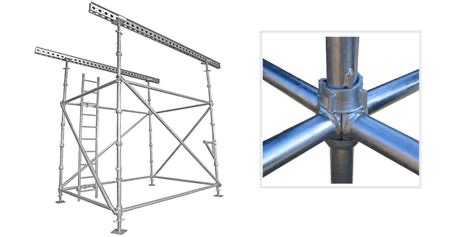

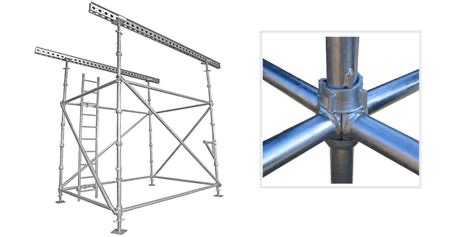

The scaffolding cuplock system is one of the most popular modular scaffolding systems worldwide, widely used in construction, industrial maintenance, and civil engineering projects. This system is renowned for its strength, versatility, and rapid assembly. Understanding the scaffolding cuplock system specifications is crucial for engineers, contractors, and safety inspectors to ensure safe and efficient scaffold erection.

What Is the Cuplock Scaffolding System?

The cuplock scaffolding system is a modular steel scaffolding system characterized by its unique locking mechanism, which uses a top cup and bottom cup welded at regular intervals on vertical tubes (standards). Horizontal tubes (ledgers) and braces are connected to these cups using a simple but secure locking action, allowing up to four horizontal members to be connected to a vertical standard at the same node point.

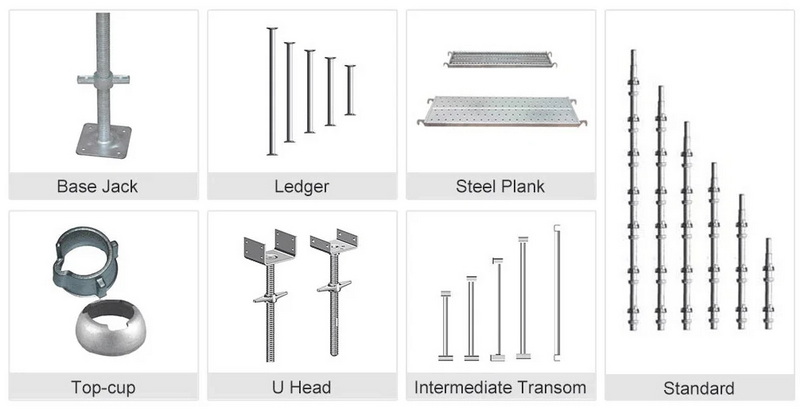

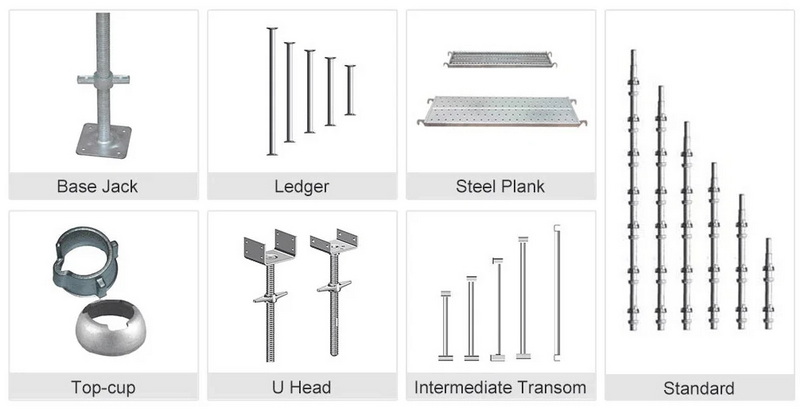

Core Components and Their Specifications

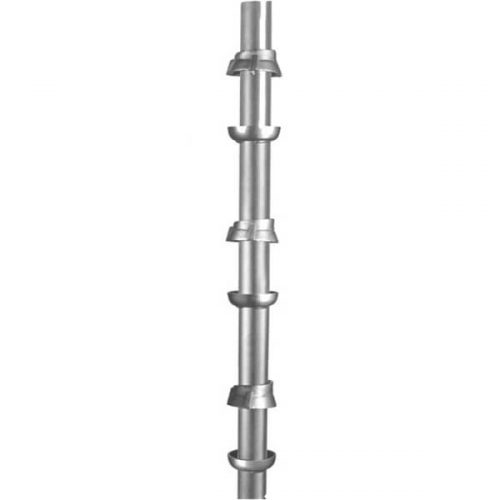

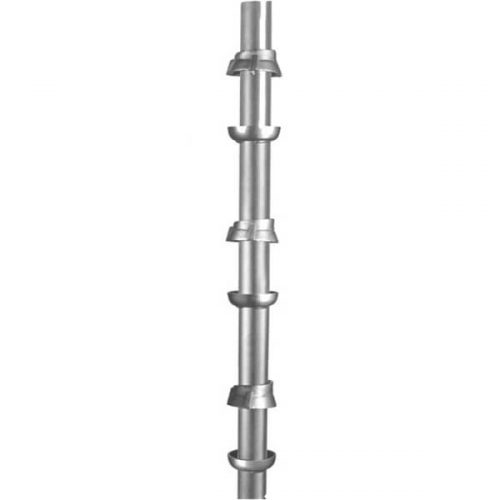

1. Cuplock Standards (Verticals)

- Material: High tensile steel, commonly Q235 or Q345 grade.

- Tube Diameter: Outer diameter (OD) of 48.3 mm.

- Wall Thickness: Typically 3.2 mm or 4.0 mm.

- Length Options: Available in various lengths such as 0.5m, 1.0m, 1.5m, 2.0m, 2.5m, 3.0m, and custom sizes.

- Cup Spacing: Bottom and top cups welded at 500 mm (0.5 m) intervals.

- Top Spigot: A 150 mm long spigot at the top allows vertical connection of additional standards.

- Weight: Varies by length and thickness; e.g., a 2.0 m standard with 3.25 mm thickness weighs approximately 11.82 kg.

2. Cuplock Ledgers (Horizontals)

- Material: Same grade steel as standards.

- Tube Diameter: 48.3 mm OD.

- Wall Thickness: Usually 3.2 mm.

- Length: Commonly 2.5 m or 3.0 m.

- Connection: Inserted into the bottom cup of the standard, then locked in place by rotating the top cup.

3. Cuplock Braces (Swivel Braces)

- Material: 48.3 mm OD steel tube with 3.2 mm thickness.

- Function: Provide diagonal bracing for lateral stability.

- Couplers: Swivel couplers with locking mechanisms prevent accidental movement.

- Sizes: Various lengths such as 1.5 m, 2.0 m, 2.5 m, and 3.0 m.

4. Other Accessories

- Base Plates: Provide stable footing for standards.

- Ledger End Caps: Protect tube ends.

- Guardrails and Toe Boards: For worker safety.

- Stair Units and Ladders: For access.

Material and Manufacturing Standards

- Steel Grade: Most cuplock components are made from Q235 or Q345 high tensile steel, ensuring high strength and durability.

- Surface Treatment: Hot-dip galvanizing is common to provide corrosion resistance, extending the life of scaffolding in outdoor environments. Painted or powder-coated finishes are also available.

- Welding: Cups are welded onto the standards at precise intervals (every 0.5 m) using automated welding processes to ensure consistency and strength.

- Dimensional Tolerances: Components conform to international standards such as EN 12810 and EN 12811, ensuring interchangeability and safety compliance.

Load Capacities and Structural Strength

Vertical Load (Leg Capacity)

- The cuplock standard's vertical leg capacity varies with tube thickness and length.

- For example, a 48.3 mm OD tube with 3.2 mm thickness can support leg loads up to 40 kN when the ledger lift is 1.5 m.

- Shorter ledger lifts (e.g., 1.0 m) can increase leg capacity up to 55 kN.

- Longer lifts (e.g., 2.0 m) reduce leg capacity to approximately 29 kN.

- These values depend on proper assembly, bracing, and load distribution.

Horizontal Load

- Ledgers and braces provide lateral stability and support platform loads.

- The rigid locking mechanism of the cuplock system ensures minimal movement and high resistance to shear forces.

Safety Factors

- Design incorporates safety factors per international scaffolding codes.

- The locking cups provide a positive mechanical lock, preventing accidental disengagement.

Assembly and Locking Mechanism

The cuplock system's unique feature is its node-point locking device:

- Lower Cup: Fixed to the standard at 0.5 m intervals, it holds the ledger's forged blade.

- Upper Cup: A rotating cup that slides over the ledger blade and locks it in place by a simple twist or hammer blow.

- This design allows up to four ledgers to be connected at a single node, enabling quick, secure assembly.

Advantages of the Cuplock System

- Fast Assembly: The integrated locking system reduces the need for nuts, bolts, or wedges, speeding up erection by 30-50% compared to traditional scaffolding.

- Versatility: Suitable for facade scaffolding, shoring, circular structures, staircases, birdcage scaffolds, and mobile towers.

- Safety: Positive locking and reduced loose components improve safety on site.

- Durability: Hot-dip galvanized finish protects against corrosion.

- Modularity: Components are interchangeable and customizable.

Typical Applications

- Building Facades: Easy to adapt to irregular surfaces.

- Industrial Plants: Supports heavy loads and complex structures.

- Bridge and Tunnel Construction: Customizable for curved and uneven surfaces.

- Event Staging: Rapid assembly and dismantling.

- Formwork Support: Strong enough for heavy concrete loads.

Conclusion

The scaffolding cuplock system specifications define a robust, versatile, and safe scaffolding solution widely adopted in modern construction. Its modular design, standardized dimensions, and unique locking mechanism allow for rapid assembly, high load capacity, and adaptability to complex structures. Understanding these specifications ensures that project managers and site engineers can select, assemble, and maintain cuplock scaffolding safely and effectively.By adhering to these standards and best practices, the cuplock system continues to be a trusted choice for scaffolding needs worldwide.

FAQ

1. What are the standard dimensions of cuplock scaffolding standards?

Cuplock standards are typically 48.3 mm in diameter with wall thicknesses of 3.2 or 4.0 mm, available in lengths from 0.5 m to 3.5 m or customized sizes.

2. How often are the locking cups welded on the standards?

Locking cups are welded at 500 mm intervals along the standard to provide consistent and modular connection points.

3. What materials are used for cuplock scaffolding components?

High tensile steel (Q235 or Q345) is used, with hot-dip galvanizing as the most common surface treatment for corrosion resistance.

4. How much load can a cuplock standard support?

Depending on the ledger lift, cuplock standards can support vertical leg loads from approximately 29 kN to 55 kN.

5. Is the cuplock system compliant with international safety standards?

Yes, the cuplock system complies with EN 12810, EN 12811, and other regional standards ensuring safety and reliability.