Content Menu

● Introduction to Cuplock Scaffolding

● Key Components of Cuplock Scaffolding

● Cuplock Scaffolding Drawings

● Components Included in Cuplock Scaffolding Drawings

● Benefits of Cuplock Scaffolding Drawings

● Applications of Cuplock Scaffolding

● Design Considerations for Cuplock Scaffolding

● Maintenance and Inspection of Cuplock Scaffolding

● Conclusion

● FAQ

>> 1. What are the main components of cuplock scaffolding?

>> 2. How do cuplock scaffolding drawings contribute to construction efficiency?

>> 3. What are the benefits of using cuplock scaffolding over traditional scaffolding systems?

>> 4. Can cuplock scaffolding be customized for specific construction needs?

>> 5. What safety features should be included in cuplock scaffolding drawings?

● Citations:

Cuplock scaffolding is a widely used modular scaffolding system in construction projects due to its efficiency, safety, and cost-effectiveness. It consists of vertical standards, horizontal ledgers, and diagonal braces, all connected through a unique locking mechanism. This article will delve into the components and details typically included in standard cuplock scaffolding drawings, highlighting their importance in ensuring safe and efficient construction processes.

Introduction to Cuplock Scaffolding

Cuplock scaffolding is renowned for its simplicity and speed of assembly. It uses a "cup and blade" locking system, where vertical standards have cups welded at regular intervals, and horizontal ledgers are connected to these standards using blades that fit into the cups. This system allows for quick and secure assembly without the need for nuts and bolts, making it a preferred choice for many construction projects.

Key Components of Cuplock Scaffolding

1. Vertical Standards: These are the upright poles of the scaffolding, typically made from Q355 or S355 steel with a diameter of 48.3mm and a thickness of 3.2mm. They have cups welded at 500mm intervals to connect the ledgers.

2. Horizontal Ledgers: These are the horizontal beams that connect the vertical standards. They also have a diameter of 48.3mm and a thickness of 3.2mm, with sizes ranging from 900mm to 3000mm.

3. Diagonal Braces: These provide additional stability to the scaffolding structure. They are typically made from the same material as the standards but with a thickness of 2.5mm.

4. Planks: These are the platforms on which workers stand. They are usually made of wood or aluminum and are placed on top of the ledgers.

5. Safety Accessories: Include handrails, toe boards, and access ladders, which are crucial for ensuring worker safety.

Cuplock Scaffolding Drawings

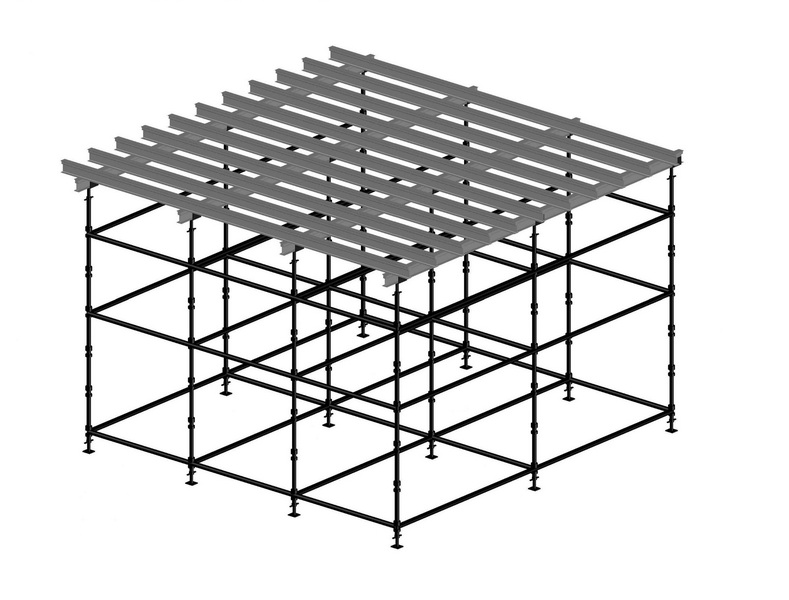

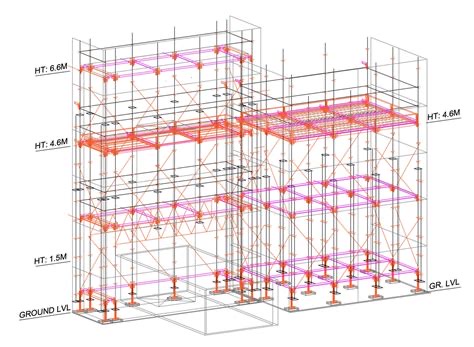

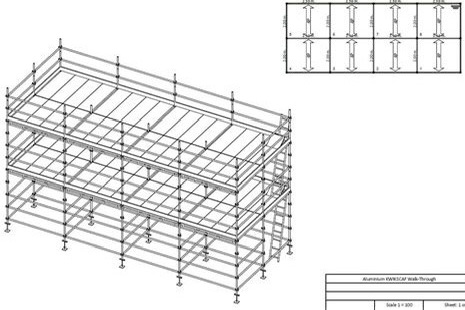

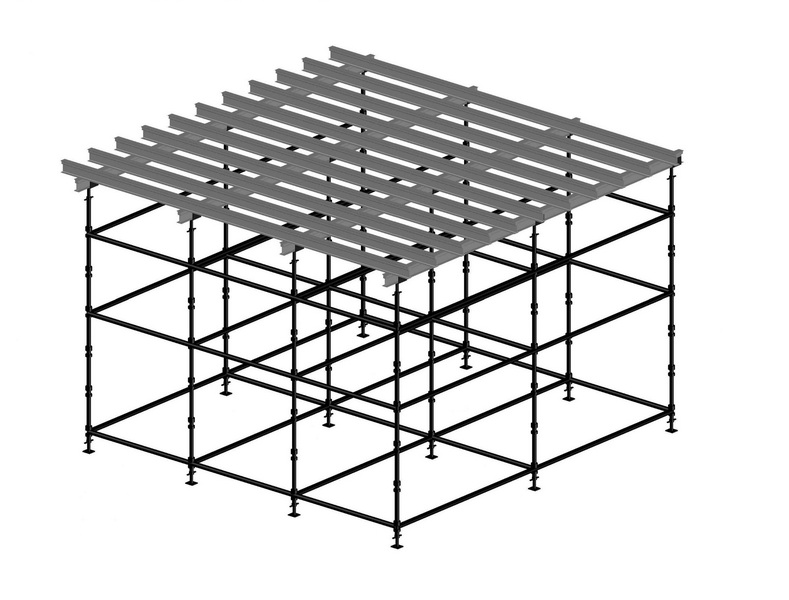

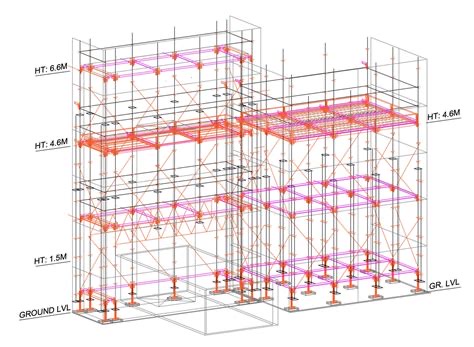

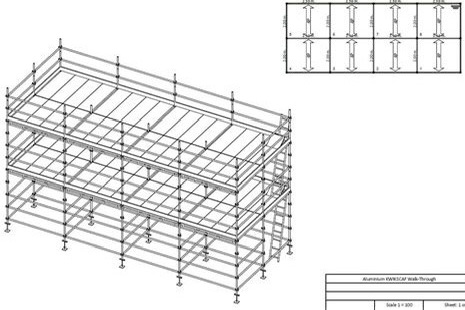

Cuplock scaffolding drawings are detailed diagrams that outline the layout and specifications of the scaffolding structure. These drawings are crucial for ensuring that the scaffolding is erected safely and efficiently.

Components Included in Cuplock Scaffolding Drawings

1. Layout Plan: This shows the overall layout of the scaffolding, including the position of vertical standards, horizontal ledgers, and diagonal braces.

2. Elevation View: This provides a side view of the scaffolding, detailing the height and positioning of each component.

3. Sectional Details: These show the cross-sectional details of how components are connected, such as how ledgers fit into the cups on the vertical standards.

4. Material Specifications: This includes information about the type of steel used, the thickness, and the surface treatment (e.g., hot-dip galvanized).

5. Safety Features: Details on safety features such as handrails, toe boards, and access ladders are also included.

6. Load Calculations: These ensure that the scaffolding can support the intended load, including workers, materials, and equipment.

7. Foundation Details: Information on how the scaffolding is anchored to the ground to prevent movement or collapse.

Benefits of Cuplock Scaffolding Drawings

Cuplock scaffolding drawings offer several benefits:

- Efficiency: They help in planning and executing the scaffolding setup quickly, reducing construction time.

- Safety: By ensuring that all components are correctly positioned and secured, these drawings enhance the stability and safety of the scaffolding.

- Cost-Effectiveness: Proper planning reduces waste and minimizes the need for additional materials or labor.

Applications of Cuplock Scaffolding

Cuplock scaffolding is versatile and can be used in a variety of applications:

- Facade Scaffolding: Ideal for exterior work on buildings.

- Formwork Support: Used to support concrete formwork.

- Maintenance Access: Provides safe access for maintenance tasks.

- Stair Access and Birdcages: Can be configured to create stair towers and birdcage scaffolds.

Design Considerations for Cuplock Scaffolding

When designing cuplock scaffolding, several factors must be considered:

- Site Conditions: The scaffolding must be adapted to the site's terrain and environmental conditions.

- Load Requirements: The scaffolding must be designed to support the intended loads safely.

- Regulatory Compliance: Designs must comply with local safety regulations and standards.

Maintenance and Inspection of Cuplock Scaffolding

Regular maintenance and inspection are crucial to ensure the longevity and safety of cuplock scaffolding:

- Daily Inspections: Before use, scaffolding should be inspected for damage or wear.

- Regular Maintenance: Components should be checked for corrosion and wear, and replaced as necessary.

Conclusion

Cuplock scaffolding drawings are essential tools for ensuring the safe and efficient construction of scaffolding structures. They provide detailed information on the layout, components, and specifications necessary for erecting a stable and secure scaffolding system. By understanding and utilizing these drawings effectively, construction teams can optimize their scaffolding setup processes, reduce costs, and enhance workplace safety.

FAQ

1. What are the main components of cuplock scaffolding?

The main components of cuplock scaffolding include vertical standards, horizontal ledgers, diagonal braces, and planks. Each component plays a crucial role in the stability and functionality of the scaffolding.

2. How do cuplock scaffolding drawings contribute to construction efficiency?

Cuplock scaffolding drawings contribute to construction efficiency by providing a clear plan for the scaffolding setup. This helps in reducing assembly time and minimizing errors, which in turn saves labor costs and project timelines.

3. What are the benefits of using cuplock scaffolding over traditional scaffolding systems?

Cuplock scaffolding offers several benefits over traditional systems, including faster assembly and disassembly, enhanced safety due to its secure locking mechanism, and cost-effectiveness through reusable components.

4. Can cuplock scaffolding be customized for specific construction needs?

Yes, cuplock scaffolding can be customized to meet specific construction needs. Manufacturers often provide customized standards and configurations to suit different site requirements.

5. What safety features should be included in cuplock scaffolding drawings?

Safety features such as handrails, toe boards, and access ladders should be included in cuplock scaffolding drawings to ensure worker safety during construction.

Citations:

[1] https://www.youtube.com/watch?v=wBKilb9ALEY

[2] https://rapid-scafform.com/cuplock-scaffold/

[3] https://support.scaffplan.com/cuplock-added?kb_language=en_US

[4] https://patents.google.com/patent/CN102561669A/en

[5] https://www.youtube.com/watch?v=ojYR6MRAoEI

[6] https://www.wm-scaffold.com/cup-lock-scaffold.html

[7] https://www.oguzhaniskele.com/en/bilgilendirme/sikca-sorulan-sorular

[8] https://patents.google.com/patent/CN202416822U/en

[9] https://www.youtube.com/watch?v=fnJw0xLZE5s

[10] https://jumplyscaffolding.com/what-is-cuplock-scaffolding/

[11] https://scaffolding-solutions.com.cy/wp-content/uploads/2022/06/user_manual_cuplok_10-2006.pdf