Content Menu

● Understanding Scaffolding Tags

● The Meaning of a Yellow Tag

>> Key Features of Yellow Tags

● When Is a Yellow Tag Used?

● Importance of Compliance with Yellow Tags

● Best Practices for Using Scaffolding with Yellow Tags

● The Role of Competent Persons in Scaffold Safety

● Common Hazards Associated with Scaffolding

● Training Programs for Scaffold Safety

● Conclusion

● FAQ

>> 1. What should I do if I see a yellow tag on scaffolding?

>> 2. Can I remove a yellow tag once I feel it's safe?

>> 3. How often should scaffolding be inspected?

>> 4. What happens if I ignore a yellow tag?

>> 5. Are there legal requirements for using scaffolding tags?

● Citations:

Scaffolding is an essential part of construction and maintenance projects, providing workers with safe access to elevated areas. However, scaffolding can also pose significant risks if not properly maintained and inspected. To enhance safety, a color-coded tagging system is employed to communicate the status of scaffolding systems. Among these tags, the yellow tag holds particular importance, indicating caution and the need for special attention. This article delves into what a yellow tag on an inspected scaffolding system means, its implications for safety, and best practices for using scaffolding safely.

Understanding Scaffolding Tags

Scaffolding tags serve as visual indicators of the safety status of scaffolding structures. They are typically attached at key access points and come in three primary colors: green, yellow, and red. Each color conveys specific information about the scaffold's condition:

- Green Tag: Indicates that the scaffold has been inspected and is safe for use.

- Yellow Tag: Signifies that while the scaffold has been inspected, there are potential hazards or modifications that require caution.

- Red Tag: Warns that the scaffold is unsafe for use and should not be approached.

This tagging system is crucial for maintaining safety standards on construction sites, as it provides immediate visual communication regarding the usability of scaffolding.

The Meaning of a Yellow Tag

A yellow tag on an inspected scaffolding system means that the scaffold is safe to use but has undergone modifications or presents potential hazards that users need to be aware of. This tag serves as a cautionary measure, alerting workers to exercise additional care when using the scaffold.

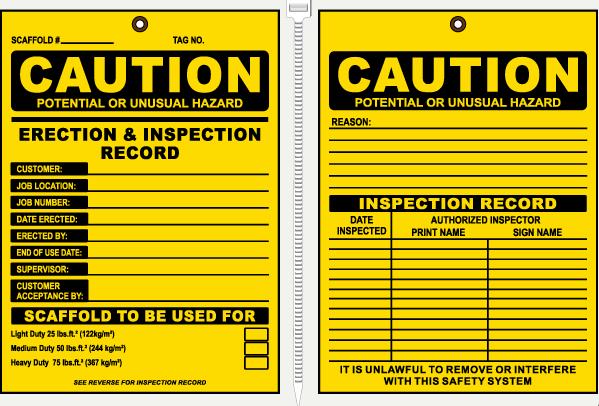

Key Features of Yellow Tags

- Cautionary Message: The yellow tag indicates that while the scaffold can be used, it may not meet all standard safety requirements due to modifications made for specific work needs.

- Inspection Status: The tag confirms that an inspection has been conducted by a competent person but also highlights that further attention may be necessary.

- Documentation: Yellow tags typically include details such as identified hazards, required preventive measures, and the name of the individual authorizing its use.

When Is a Yellow Tag Used?

Yellow tags are employed in various scenarios where scaffolding has been modified or presents potential risks. Common situations include:

- Modifications for Specific Tasks: If a scaffold has been altered to accommodate specific job requirements (e.g., adding extra platforms or changing load capacities), a yellow tag will be issued.

- Identified Hazards: If an inspection reveals potential safety concerns—such as loose components or inadequate bracing—a yellow tag will be placed on the scaffold until these issues are resolved.

- Temporary Conditions: In situations where scaffolding may be temporarily unsafe (e.g., during adverse weather), a yellow tag serves as a warning to users.

Importance of Compliance with Yellow Tags

Understanding and adhering to the implications of yellow tags is crucial for ensuring workplace safety. Here are some reasons why compliance is important:

- Risk Mitigation: By recognizing that a yellow tag indicates potential hazards, workers can take necessary precautions to prevent accidents.

- Enhanced Communication: Yellow tags facilitate clear communication among team members regarding the status of scaffolding systems.

- Regulatory Compliance: Many safety regulations require proper tagging and inspection protocols to minimize risks associated with working at heights.

Best Practices for Using Scaffolding with Yellow Tags

To ensure safety when using scaffolding marked with a yellow tag, consider the following best practices:

1. Read and Understand the Tag: Before using any scaffold with a yellow tag, thoroughly read the information provided on the tag regarding identified hazards and necessary precautions.

2. Conduct Additional Inspections: Ensure that further inspections are conducted regularly to assess any changes in conditions or hazards associated with the scaffold.

3. Use Personal Protective Equipment (PPE): Workers should wear appropriate PPE such as helmets, harnesses, and fall protection systems when using scaffolds marked with yellow tags.

4. Limit Access: Restrict access to only those workers who are trained and aware of the specific risks associated with using modified scaffolds.

5. Report Issues Promptly: If any new hazards are identified while using a scaffold with a yellow tag, report them immediately to a supervisor or safety officer.

The Role of Competent Persons in Scaffold Safety

A competent person plays a vital role in ensuring scaffold safety. This individual is responsible for inspecting scaffolds before use and ensuring compliance with safety regulations. Their responsibilities include:

- Conducting thorough inspections before scaffolds are put into service.

- Ensuring that all modifications made to scaffolds are documented and communicated effectively.

- Authorizing the use of scaffolds marked with yellow tags after assessing potential hazards.

- Providing training and guidance to workers on how to safely use scaffolds marked with cautionary tags.

The presence of a competent person can significantly reduce risks associated with working at heights by ensuring that all safety protocols are followed diligently.

Common Hazards Associated with Scaffolding

Understanding common hazards associated with scaffolding can help workers take proactive measures to ensure their safety. Some prevalent hazards include:

- Falls from Heights: One of the most significant risks when working on scaffolds is falling from heights due to improper use or lack of fall protection measures.

- Scaffold Collapse: Inadequate bracing or overloading can lead to scaffold collapse, posing serious risks to workers below.

- Falling Objects: Tools or materials falling from elevated platforms can cause injuries to workers on lower levels if proper containment measures are not in place.

- Electrical Hazards: Proximity to overhead power lines can create electrical hazards if proper precautions are not taken during scaffold setup and use.

By being aware of these hazards, workers can adopt safer practices when working on or around scaffolds marked with yellow tags.

Training Programs for Scaffold Safety

Implementing effective training programs is essential for promoting scaffold safety among workers. These programs should cover:

- Understanding different types of scaffold tags and their meanings.

- Proper setup and dismantling procedures for scaffolds.

- Hazard recognition and risk assessment techniques.

- Emergency response procedures in case of accidents or incidents involving scaffolds.

Regular training sessions not only enhance worker awareness but also foster a culture of safety within organizations involved in construction activities.

Conclusion

In summary, a yellow tag on an inspected scaffolding system serves as an important cautionary signal indicating that while the scaffold may be usable, there are potential hazards or modifications that require careful attention from users. Understanding what this tag means is essential for maintaining safety on construction sites and preventing accidents related to scaffolding usage. By adhering to best practices and ensuring compliance with tagging protocols, workers can significantly reduce risks associated with working at heights.

FAQ

1. What should I do if I see a yellow tag on scaffolding?

If you see a yellow tag, read it carefully to understand any potential hazards or modifications indicated. Use caution when accessing or working on that scaffold.

2. Can I remove a yellow tag once I feel it's safe?

No, a yellow tag should only be removed by a competent person after conducting an inspection confirming that all issues have been resolved and it is safe for use again.

3. How often should scaffolding be inspected?

Scaffolding should be inspected before each work shift and after any occurrence that could affect its structural integrity.

4. What happens if I ignore a yellow tag?

Ignoring a yellow tag can lead to serious accidents or injuries due to unaddressed hazards or unsafe conditions associated with modified scaffolds.

5. Are there legal requirements for using scaffolding tags?

While specific tagging systems may not be legally mandated in all regions, regular inspections and proper tagging practices are essential for compliance with safety regulations like OSHA standards in many jurisdictions.

Citations:

[1] https://www.linkedin.com/pulse/what-scaffold-tagging-types-enhancing-safety-height-youngman-india

[2] https://coreehs.com/scaffolding-safety-enhancing-accident-prevention-with-tagging-system/

[3] https://www.safetylock.net/product/yellow-color-scaffolding-tags-scaffold-use-tag-es-yst-sut/

[4] https://primeliftsafetyng.com/2024/06/04/requirements-for-scaffold-inspection/

[5] https://www.seton.com/resource-center/wp-content/uploads/2016/07/SUS-Scaffolding-Tags-Compliance-Guide.pdf

[6] https://scaffoldingrentalandsales.com/blog/scaffolding-tags-and-their-use-/

[7] https://www.s-pgroup.com/blog/blog-8/a-guide-to-different-types-of-scaffolding-tags-53

[8] https://1streporting.com/blog/vehicles-equipment/scaffolding-tagging/

[9] https://apacscaffold.com/the-ultimate-guide-of-scaffold-tags/

[10] https://safetyculture.com/topics/scaffolding-safety/

[11] https://www.mdpi.com/2075-5309/14/2/385

[12] https://www.scaffoldingsolutions.com/articles/11-scaffolding-safety-tips/

[13] https://www.youtube.com/watch?v=mSdsuRPaPAA