Content Menu

● Introduction to Ringlock Scaffolding Catalogues

● Key Features of Ringlock Scaffolding Catalogues

● Contents of a Ringlock Scaffolding Catalogue

>> 1. Component Identification

>> 2. Technical Specifications

>> 3. Assembly Instructions

>> 4. Safety Guidelines

>> 5. Application Examples

● Advanced Features and Accessories

● Environmental Considerations

● Future Developments

● Conclusion

● FAQ

>> 1. What Information Does a Ringlock Scaffolding Catalogue Typically Include?

>> 2. What Materials Are Used in Ringlock Scaffolding?

>> 3. What Are the Common Applications of Ringlock Scaffolding?

>> 4. How Does Ringlock Scaffolding Compare to Traditional Systems?

>> 5. What Safety Considerations Should Be Taken When Using Ringlock Scaffolding?

● Citations:

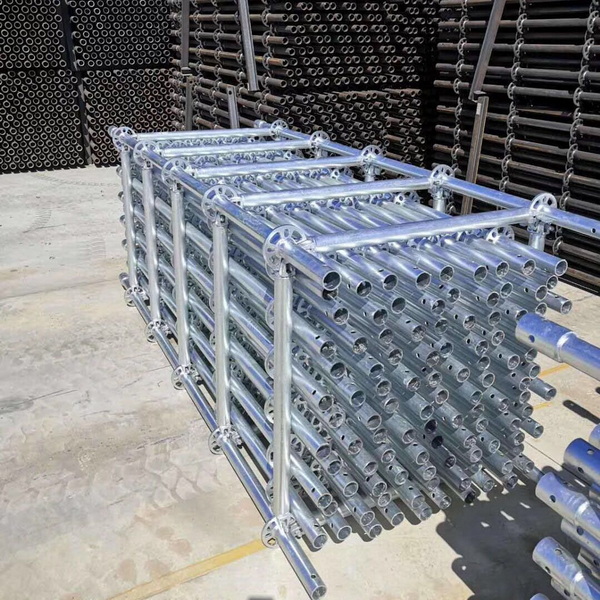

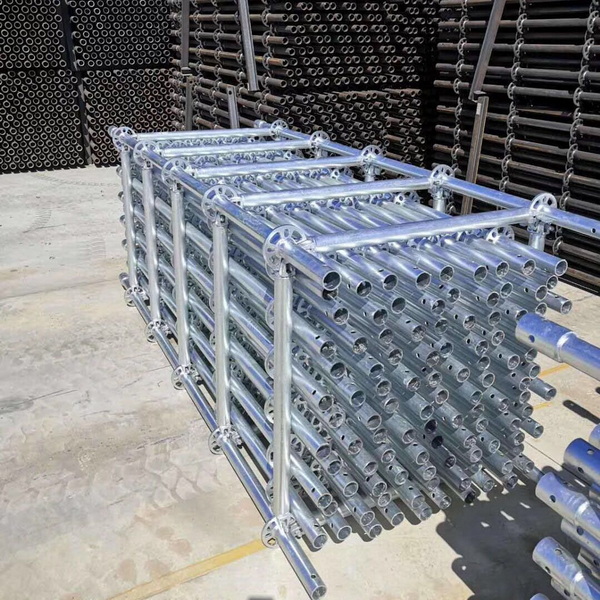

A ringlock scaffolding catalogue is a comprehensive resource that provides detailed information about the components, specifications, and applications of ringlock scaffolding systems. This article will explore the typical contents of a ringlock scaffolding catalogue, including component identification, technical specifications, safety guidelines, and application examples.

Introduction to Ringlock Scaffolding Catalogues

Ringlock scaffolding catalogues are designed to assist contractors, engineers, and construction managers in selecting the right scaffolding components for their projects. These catalogues typically include detailed descriptions of each component, assembly instructions, and safety guidelines to ensure safe and efficient use of the scaffolding system.

Key Features of Ringlock Scaffolding Catalogues

- Component Identification: Detailed descriptions and diagrams of each component, including standards, ledgers, braces, and base jacks.

- Technical Specifications: Dimensions, weights, and material types for each component.

- Assembly Instructions: Step-by-step guides on how to assemble and disassemble the scaffolding.

- Safety Guidelines: Important safety measures to follow during assembly, use, and disassembly.

Contents of a Ringlock Scaffolding Catalogue

1. Component Identification

Ringlock scaffolding catalogues list the basic components of the system, which typically include:

- Standards: Vertical posts with rosettes for connecting ledgers and braces.

- Ledgers: Horizontal beams that connect standards.

- Braces: Diagonal or horizontal supports for stability.

- Base Jacks: Adjustable bases for leveling the scaffolding.

2. Technical Specifications

Catalogues provide detailed technical specifications for each component, including:

- Dimensions: Lengths and diameters of standards, ledgers, and braces.

- Weights: Weight of each component for transportation and handling considerations.

- Material Types: Information on the materials used, such as steel or aluminum, and any coatings like hot-dip galvanization.

| Component | Dimension (mm) | Weight (kg) | Material |

| Standard | 1500-3000 | 7.94-14.99 | Steel |

| Ledger | 1500-3000 | 5.62-10.32 | Steel |

| Brace | Varies | 2.24-6.78 | Steel |

3. Assembly Instructions

Catalogues include step-by-step assembly instructions to ensure safe and efficient setup of the scaffolding. These instructions cover:

- Preparation: Site preparation and base setup.

- Erection: Installing standards, ledgers, and braces.

- Safety Measures: Ensuring stability and securing the structure.

4. Safety Guidelines

Safety guidelines are crucial for preventing accidents and ensuring compliance with regulations. Catalogues typically cover:

- Elementary Safety Warnings: General safety precautions.

- Safe Use Practices: Proper handling and maintenance of components.

- Regulatory Compliance: Information on meeting local and international safety standards.

5. Application Examples

Ringlock scaffolding catalogues often include examples of how the system can be used in various construction projects, such as:

- Residential and commercial buildings

- Infrastructure projects (roads, bridges)

- Industrial settings (shipyards, petrochemical plants)

Advanced Features and Accessories

Ringlock scaffolding catalogues may also highlight advanced features and accessories that enhance the system's versatility and efficiency. These include:

- Mid-transoms: Allow for openings in the working platform to accommodate obstacles.

- Crane Displacement Accessories: Enable safe crane operations without redesigning the scaffold structure.

Environmental Considerations

The durability and low maintenance requirements of ringlock scaffolding reduce waste and minimize environmental impact. The hot-dip galvanized finish ensures that the scaffolding can withstand harsh weather conditions without corroding.

Future Developments

As construction technology advances, ringlock scaffolding continues to evolve with new materials and designs. Innovations in steel and aluminum alloys are expected to further enhance its strength and durability.

Conclusion

A ringlock scaffolding catalogue is an essential resource for anyone involved in construction projects. It provides comprehensive information on components, assembly instructions, safety guidelines, and application examples, ensuring that users can safely and efficiently utilize the ringlock scaffolding system.

FAQ

1. What Information Does a Ringlock Scaffolding Catalogue Typically Include?

A ringlock scaffolding catalogue includes component identification, technical specifications, assembly instructions, safety guidelines, and application examples.

2. What Materials Are Used in Ringlock Scaffolding?

Ringlock scaffolding is primarily made from high-strength steel, often coated with hot-dip galvanization to resist corrosion.

3. What Are the Common Applications of Ringlock Scaffolding?

Ringlock scaffolding is commonly used in residential and commercial construction, infrastructure projects, and industrial settings.

4. How Does Ringlock Scaffolding Compare to Traditional Systems?

Ringlock scaffolding offers faster assembly, higher versatility, and superior load-bearing capacity compared to traditional tube and clamp systems.

5. What Safety Considerations Should Be Taken When Using Ringlock Scaffolding?

Safety considerations include ensuring all components are in good condition, following proper assembly and disassembly procedures, and maintaining a safe distance from power lines.

Citations:

[1] https://direct.doka.com/_ext/downloads/downloadcenter/999817902_2023_09_online.pdf

[2] https://apacsafety.com/ultimate-guide-of-ringlock-scaffold/

[3] https://www.scafom-rux.com/en/scaffolding-blog/beginner-s-guide-to-scaffolding-types-the-ringlock-scaffold

[4] https://www.defenal.com/pdf/ringlock-scaffolding.pdf

[5] https://www.doka.com/en/system-groups/doka-working-scaffold-systems/working-scaffolds/ringlock/ringlock

[6] https://www.wm-scaffold.com/what-is-ringlock/

[7] https://www.ekscaffolding.com/ringlock-scaffolding.html

[8] https://wellmadescaffold.en.made-in-china.com/product-group/oMdEHWBACJkc/Ring-Lock-Scaffolding-catalog-1.html

[9] https://irp.cdn-website.com/57406b1b/files/uploaded/AT-PAC_ProductCatalogue_UK_v2p2.pdf