Content Menu

● Introduction to Coupler Scaffolding Clamps

● Types of Coupler Scaffolding Clamps

● How Coupler Scaffolding Clamps Work

● Safety Considerations

● Applications of Coupler Scaffolding Clamps

● Conclusion

● FAQ

>> 1. What are the main types of coupler scaffolding clamps?

>> 2. How do coupler scaffolding clamps ensure safety?

>> 3. What materials are coupler scaffolding clamps typically made from?

>> 4. What are some common applications of coupler scaffolding clamps?

>> 5. How should coupler scaffolding clamps be stored?

● Citations:

Coupler scaffolding clamps are essential components in the construction industry, used to connect scaffolding tubes securely, ensuring a stable and safe working platform for workers. These clamps, also known as scaffolding couplers or fittings, play a critical role in assembling tube-and-coupler scaffolding systems. In this article, we will delve into the world of coupler scaffolding clamps, exploring their types, functions, and applications, along with safety considerations and best practices for their use.

Introduction to Coupler Scaffolding Clamps

Coupler scaffolding clamps are designed to join two scaffolding tubes together, either at right angles or at various angles, depending on the type of coupler used. They are typically made from high-strength steel, such as Q235 or Q355, through processes like drop forging or pressing, ensuring they can withstand heavy loads and harsh environmental conditions[7].

Types of Coupler Scaffolding Clamps

There are several types of coupler scaffolding clamps, each serving a specific purpose in scaffolding construction:

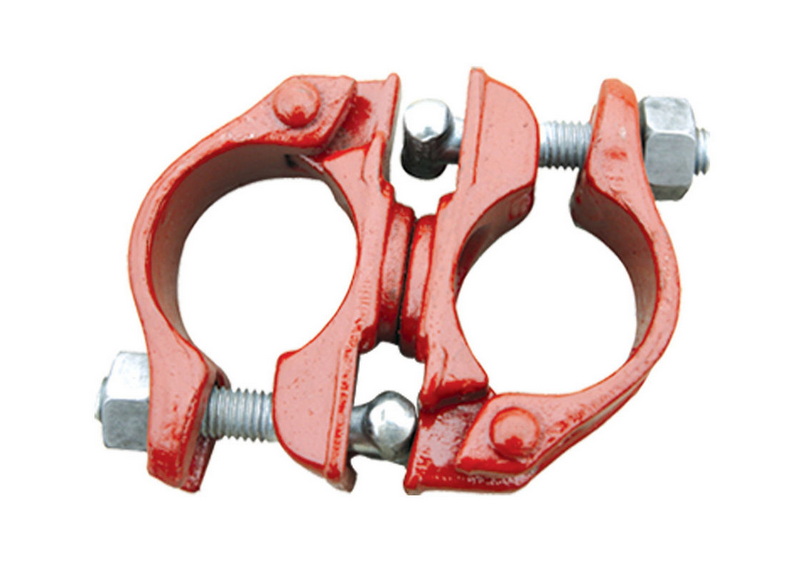

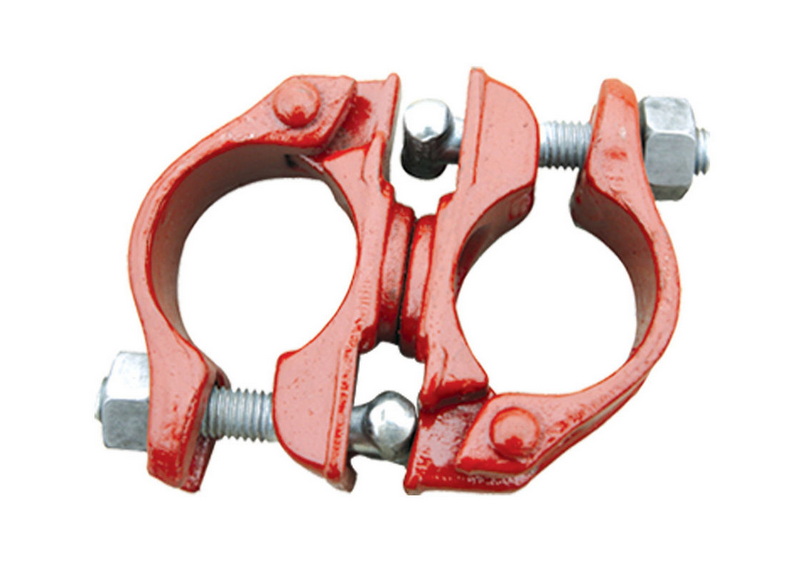

1. Double Coupler: Used to connect two scaffolding tubes at right angles, these couplers are crucial for creating stable frames in scaffolding structures. They are also known as right-angle clamps and are widely used in forming the basic framework of scaffolding[4][9].

2. Swivel Coupler: Allows tubes to be connected at any angle, providing flexibility in scaffolding design and bracing. Swivel couplers are particularly useful when constructing complex scaffold configurations that require adaptability[1][4].

3. Sleeve Coupler: Used for splicing tubes end-to-end, enhancing the length of scaffolding structures. Sleeve couplers are commonly utilized when scaffolding requires longer spans or when two tubes need to be joined together to achieve the desired length[1][9].

4. Putlog Coupler: Also known as single couplers, these are used to attach transoms or putlogs to ledger tubes. They provide stability and support in scaffolding configurations where a scaffold platform is constructed on one side of a structure[1][4].

5. Board Retention Coupler: Secures boards or planks to the scaffolding frame, ensuring a safe walking surface. These couplers are essential for maintaining the structural integrity of the scaffolding platform[9].

6. Beam Clamp: Used to connect scaffold tubes to beams, ensuring the stability and safety of the beams. Beam clamps are typically used in scaffolding structures that require beam support[4][9].

How Coupler Scaffolding Clamps Work

Coupler scaffolding clamps work by securely fastening scaffolding tubes together. They are designed with locking mechanisms to prevent accidental disconnection, ensuring the stability of the scaffolding structure. The process of using these clamps involves:

1. Selection of Coupler Type: Choosing the appropriate coupler based on the scaffolding design and the angle at which tubes need to be connected.

2. Installation: Placing the coupler over the ends of the scaffolding tubes and tightening the nuts to secure the connection.

3. Tightening: Ensuring that all couplers are tightened to the recommended torque to prevent slipping or coming loose.

Safety Considerations

Safety is paramount when using coupler scaffolding clamps. Here are some key considerations:

1. Regular Inspection: Before each use, inspect couplers for any damage or wear. Regular inspections are crucial to ensure that couplers remain safe and functional throughout the project[6].

2. Proper Storage: Store couplers in a dry, clean environment to prevent corrosion. This helps maintain their structural integrity and extends their lifespan[2][6].

3. Training: Ensure that workers are trained in the proper use and handling of couplers. Training programs should cover assembly, inspection, and safety protocols[3].

4. Engineering Design: Ensure that the scaffolding is properly designed and engineered to support the weight of workers and materials. This includes calculating load capacities and ensuring the scaffold can bear at least four times the maximum intended load without faltering[3].

Applications of Coupler Scaffolding Clamps

Coupler scaffolding clamps are versatile and are used in various construction projects:

1. Building Construction: Essential for creating scaffolding structures that allow workers to access high areas safely. Couplers provide the necessary structural integrity for these structures[3].

2. Maintenance and Repair: Used in scaffolding setups for maintenance tasks on existing structures. Couplers ensure that the scaffolding remains stable during these operations[3].

3. Concrete Formwork: Supports concrete formwork by connecting vertical and horizontal tubes. Couplers are critical in maintaining the formwork's stability[3].

Conclusion

Coupler scaffolding clamps are indispensable in the construction industry, providing a secure and stable platform for workers. Understanding their types, functions, and safety considerations is crucial for safe and efficient scaffolding assembly. By following best practices and ensuring proper use, these clamps can significantly enhance workplace safety and productivity.

FAQ

1. What are the main types of coupler scaffolding clamps?

Coupler scaffolding clamps include double couplers, swivel couplers, sleeve couplers, putlog couplers, board retention couplers, and beam clamps, each serving specific purposes in scaffolding construction[1][9].

2. How do coupler scaffolding clamps ensure safety?

Coupler scaffolding clamps ensure safety by providing a secure connection between scaffolding tubes, preventing accidental disconnection. Regular inspection and proper tightening are also crucial for maintaining safety[6].

3. What materials are coupler scaffolding clamps typically made from?

Coupler scaffolding clamps are typically made from high-strength steel, such as Q235 or Q355, through processes like drop forging or pressing[7].

4. What are some common applications of coupler scaffolding clamps?

Common applications include building construction, maintenance and repair, and concrete formwork, where they support scaffolding structures and ensure worker safety[3].

5. How should coupler scaffolding clamps be stored?

Coupler scaffolding clamps should be stored in a dry, clean environment, away from corrosive substances, and different types should be stored separately for easy identification[2][6].

Citations:

[1] https://www.linkedin.com/pulse/comprehensive-guide-types-couplers-scaffolding-abhishek-mishra

[2] https://www.youtube.com/watch?v=D3U9C58KEpk

[3] https://scaffoldtype.com/tube-and-coupler-scaffolding/

[4] https://www.scaffoldclamps.com/blog/what-are-scaffolding-clamps

[5] https://www.youtube.com/watch?v=8pc8EyZFXsI

[6] https://foreverengineeringltd.com/how-many-types-of-scaffolding-clamp/

[7] https://www.gd-scaffold.com/scaffolding-fittings-coupler.html

[8] https://www.youtube.com/watch?v=ehKj8okfWI8

[9] https://www.wm-scaffold.com/scaffolding-coupler.html

[10] https://www.youtube.com/watch?v=ZWbx-Hmejog