Content Menu

● Components of the Cuplock Scaffolding System

● How Does Cuplock Scaffolding Work?

● Advantages of Cuplock Scaffolding

● Applications of Cuplock Scaffolding

● Safety Considerations

● Maintenance Practices

● Conclusion

● FAQ

>> 1. What materials are used in cuplock scaffolding?

>> 2. How much weight can cuplock scaffolding support?

>> 3. Is cuplock scaffolding easy to dismantle?

>> 4. Can cuplock scaffolding be used outdoors?

>> 5. What safety measures should be considered when using cuplock scaffolding?

● Citations:

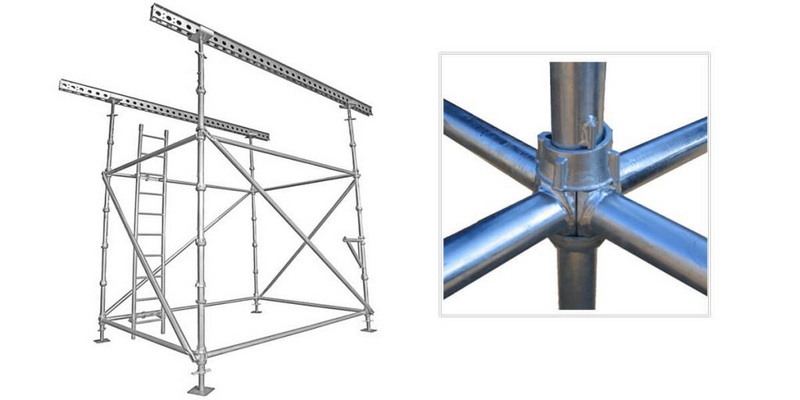

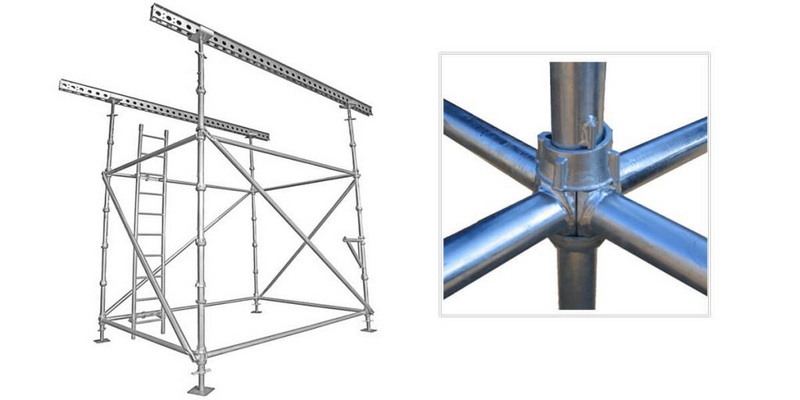

Cuplock scaffolding is a widely employed modular scaffolding system that has gained popularity due to its versatility, ease of assembly, and robust stability. Originally developed by the SGB Company (Scaffolding Great Britain), the cuplock system is designed to provide safe and efficient access for construction workers in various projects, ranging from building construction to industrial maintenance. This article will delve into the components, advantages, installation process, and applications of the cuplock scaffolding system.

Components of the Cuplock Scaffolding System

The cuplock scaffolding system consists of several key components that work together to create a stable and secure structure. The main elements include:

- Vertical Standards (Uprights): These are vertical pipes that form the backbone of the scaffolding structure. They come equipped with fixed bottom cups and movable top cups at regular intervals (usually 500mm or 1000mm) along their length.

- Ledgers (Horizontal Bars): Ledgers connect the vertical standards horizontally. They are fitted with blades at each end that lock into the cups on the verticals, providing horizontal support.

- Braces: Diagonal braces enhance the stability of the scaffolding by preventing lateral movement. They can be attached between vertical standards and ledgers.

- Base Jacks: These are adjustable supports placed at the bottom of vertical standards to ensure stability and levelness.

- Planks: These are used as walking surfaces for workers on the scaffold.

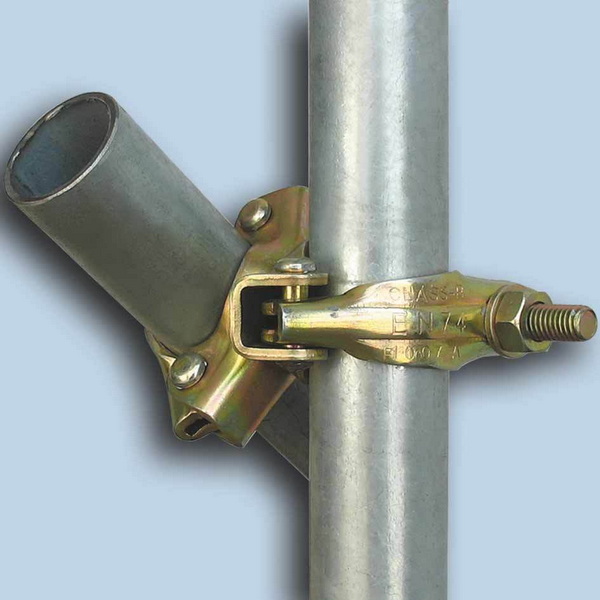

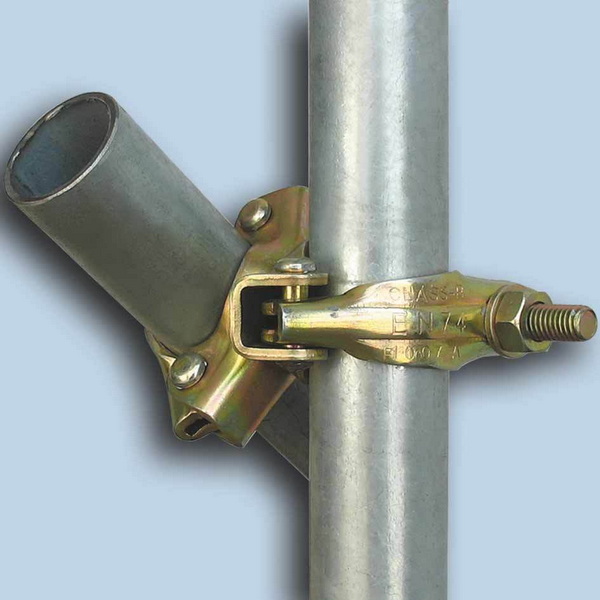

The unique feature of the cuplock system is its cup-and-blade locking mechanism, which allows for quick assembly without the need for nuts, bolts, or wedges, making it an efficient option for construction sites.

How Does Cuplock Scaffolding Work?

The cuplock scaffolding system operates on a simple yet effective locking mechanism. Each vertical standard has a fixed bottom cup welded onto it and a movable top cup that can slide up or down. The ledgers, which connect horizontally, have blades that fit into these cups.

Assembly Process:

1. Prepare the Site: Clear any debris and ensure that the ground is stable.

2. Lay Base Plates: Position base plates where vertical standards will be placed to distribute weight evenly.

3. Insert Vertical Standards: Place vertical standards into base plates and ensure they are plumb.

4. Attach Bottom Cups: Secure bottom cups onto each standard.

5. Insert Horizontal Ledgers: Fit ledgers into bottom cups.

6. Install Top Cups: Place top cups onto vertical standards to secure ledgers in place.

This method allows for rapid assembly and disassembly, making it ideal for projects requiring temporary access.

Advantages of Cuplock Scaffolding

The cuplock scaffolding system offers several benefits that contribute to its widespread use in construction:

- Speed of Assembly: The cup-and-blade mechanism allows for quick setup without needing tools like wrenches or hammers for every connection.

- Robust Stability: The design provides strong support capable of bearing heavy loads, making it suitable for various construction tasks.

- Versatility: Cuplock scaffolding can be adapted to different structures and heights, accommodating various project requirements.

- Safety Features: The absence of loose components reduces risks associated with traditional scaffolding systems, creating a safer working environment.

- Cost-Effectiveness: Its modular nature allows for efficient use of materials and labor, reducing overall project costs.

Applications of Cuplock Scaffolding

Cuplock scaffolding is utilized in numerous construction scenarios due to its adaptability:

- Building Construction: Ideal for residential and commercial buildings requiring high access points.

- Industrial Maintenance: Used in factories and plants where maintenance work is needed at elevated levels.

- Infrastructure Projects: Suitable for bridges, tunnels, and other civil engineering projects requiring temporary access solutions.

- Event Structures: Often used in staging setups for concerts and events due to its quick assembly capabilities.

Safety Considerations

When using cuplock scaffolding, safety should always be a top priority. Here are some critical safety considerations:

- Regular Inspections: Conduct routine inspections of all components before use to ensure they are in good condition and free from damage.

- Proper Training: Ensure all workers involved in assembly and disassembly are adequately trained on best practices and safety protocols related to cuplock scaffolding systems.

- Load Limits: Adhere strictly to load limits specified by manufacturers or local regulations to prevent overloading the scaffold structure.

- Use of Personal Protective Equipment (PPE): Workers should wear appropriate PPE such as helmets, harnesses, gloves, and non-slip footwear while working on or around scaffolds.

- Weather Conditions: Avoid using scaffolds during adverse weather conditions such as high winds or heavy rain which could compromise stability .

Maintenance Practices

Proper maintenance is essential to prolonging the lifespan of cuplock scaffolding systems:

- Cleaning Components: Regularly clean all parts to remove debris or contaminants that may cause corrosion or weakening over time.

- Storage Conditions: Store scaffolding components in a dry environment when not in use to prevent rusting or damage from moisture.

- Periodic Checks: Schedule periodic checks on all components for signs of wear or damage; replace any compromised parts immediately .

Conclusion

The cuplock scaffolding system stands out as a highly efficient and versatile solution in construction environments where safety and rapid assembly are paramount. Its unique locking mechanism simplifies the assembly process while providing robust support for various applications. As construction demands evolve, cuplock scaffolding continues to be a preferred choice among contractors worldwide due to its reliability and adaptability across different project types.

FAQ

1. What materials are used in cuplock scaffolding?

Cuplock scaffolding is primarily made from Q355 steel pipes with a thickness of 3.2mm, ensuring durability and safety.

2. How much weight can cuplock scaffolding support?

The load-bearing capacity varies depending on configuration but generally meets European safety standards (EN 12810).

3. Is cuplock scaffolding easy to dismantle?

Yes, due to its modular design, cuplock scaffolding can be quickly dismantled just as easily as it is assembled.

4. Can cuplock scaffolding be used outdoors?

Yes, cuplock scaffolding is suitable for both indoor and outdoor applications; however, proper weather precautions should be taken during installation.

5. What safety measures should be considered when using cuplock scaffolding?

Regular inspections should be conducted to ensure all components are secure; additionally, proper training should be provided to workers on safe assembly practices.

Citations:

[1] https://www.linkedin.com/pulse/all-cuplock-scaffolding-system-sb-scaffolding-india-pvt-ltd

[2] https://www.youtube.com/watch?v=wBKilb9ALEY

[3] https://eksca.com/cuplock-scaffolding/

[4] https://aaitscaffold.com/cuplock-scaffolding/everything-about-cuplock-scaffolding-system/

[5] https://www.youtube.com/watch?v=-ScFRrK-FKo

[6] https://saudiscaffolding.com/blog/what-is-a-cuplock-scaffolding-system/

[7] https://www.sparsteel.com/blog/cuplock-scaffolding-types-uses-and-benefits/

[8] https://www.youtube.com/watch?v=QSKy3RkmKs8

[9] https://jumplyscaffolding.com/what-is-cuplock-scaffolding/

[10] https://www.internationalscaffolding.com/projects/what-is-a-cuplock-scaffolding-system/

[11] https://www.scafom-rux.com/en/scaffolding-blog/beginner-s-guide-to-scaffolding-types-the-cuplock-modular-scaffold

[12] https://primesteeltech.co.in/cuplock-scaffolding-systems-benefits-components-applications-explained.html