Content Menu

● Understanding Cuplock Scaffolding

● Key Features of Cuplock Scaffolding

● What Is a Cuplock Scaffolding Technical Manual?

● Example: Core Components Section

● Why Do You Need a Cuplock Scaffolding Technical Manual?

>> 1. Ensures Safe and Correct Assembly

>> 2. Improves Efficiency and Speed

>> 3. Facilitates Compliance with Regulations

>> 4. Supports Complex Scaffold Designs

>> 5. Maintains Scaffold Integrity Over Time

● Detailed Components and Their Functions in Cuplock Scaffolding

>> Standards (Verticals)

>> Ledgers (Horizontals)

>> Transoms

>> Braces

>> Hop-Up Brackets

>> Accessories

● Assembly Process Overview

● Safety Considerations Highlighted in the Manual

● Maintenance and Inspection

● Advantages of Using the Cuplock Scaffolding Technical Manual

● Conclusion

● FAQ

>> 1. What is the unique feature of Cuplock scaffolding that distinguishes it from other systems?

>> 2. How does the Cuplock locking mechanism work?

>> 3. What components are covered in a Cuplock scaffolding technical manual?

>> 4. Why is it important to follow the Cuplock scaffolding technical manual?

>> 5. Can Cuplock scaffolding be used for complex scaffold structures?

● Citations:

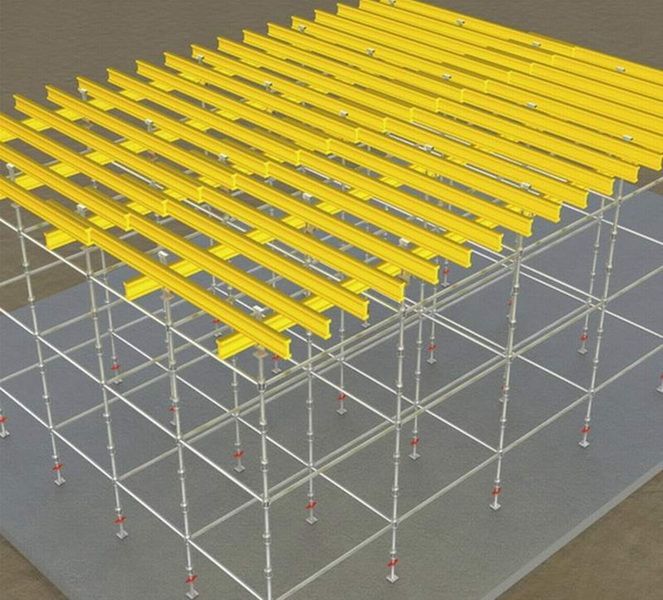

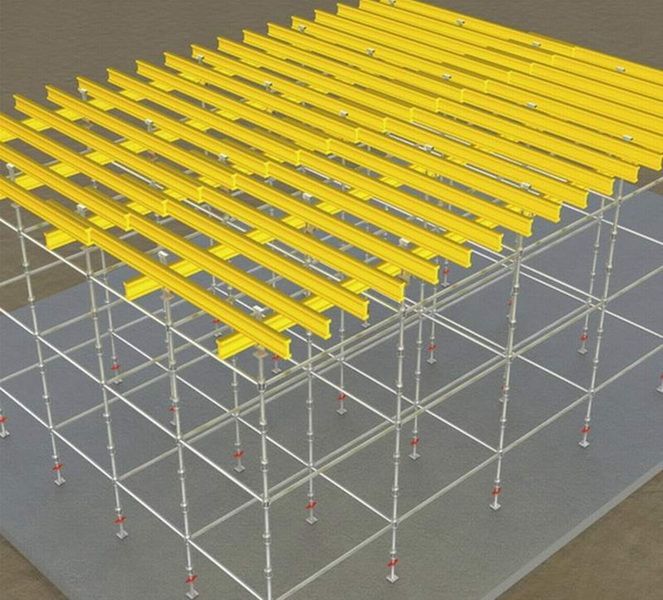

Cuplock scaffolding is a widely used modular scaffolding system known for its unique locking mechanism, speed of assembly, and versatility in construction projects. A Cuplock scaffolding technical manual is an essential document that provides detailed instructions, safety guidelines, component descriptions, and best practices for the correct and safe use of Cuplock scaffolding systems. This article explores what a Cuplock scaffolding technical manual is, why it is crucial, and how it supports efficient and safe scaffolding operations.

Understanding Cuplock Scaffolding

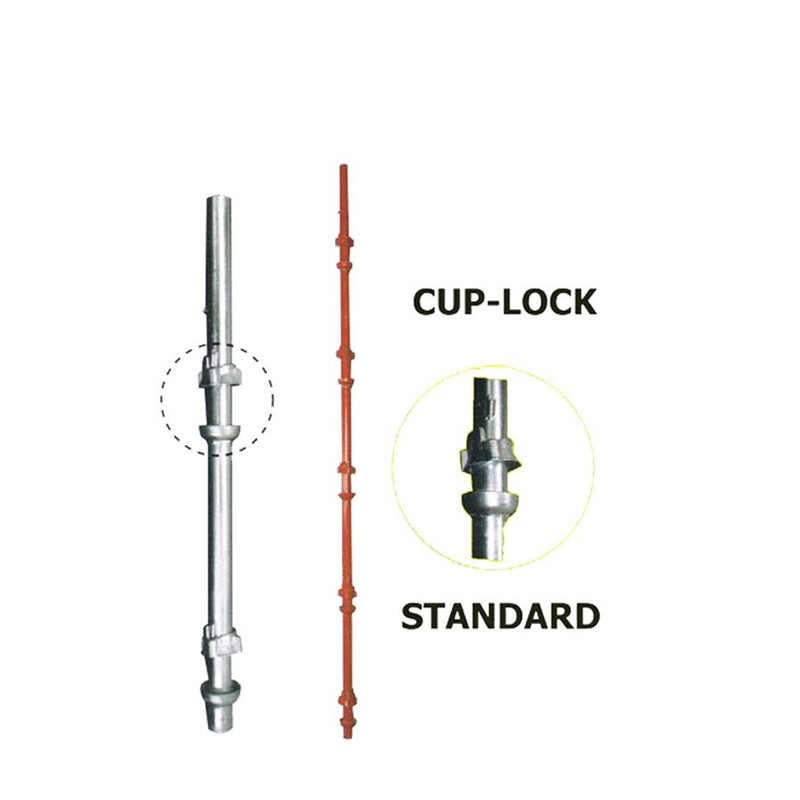

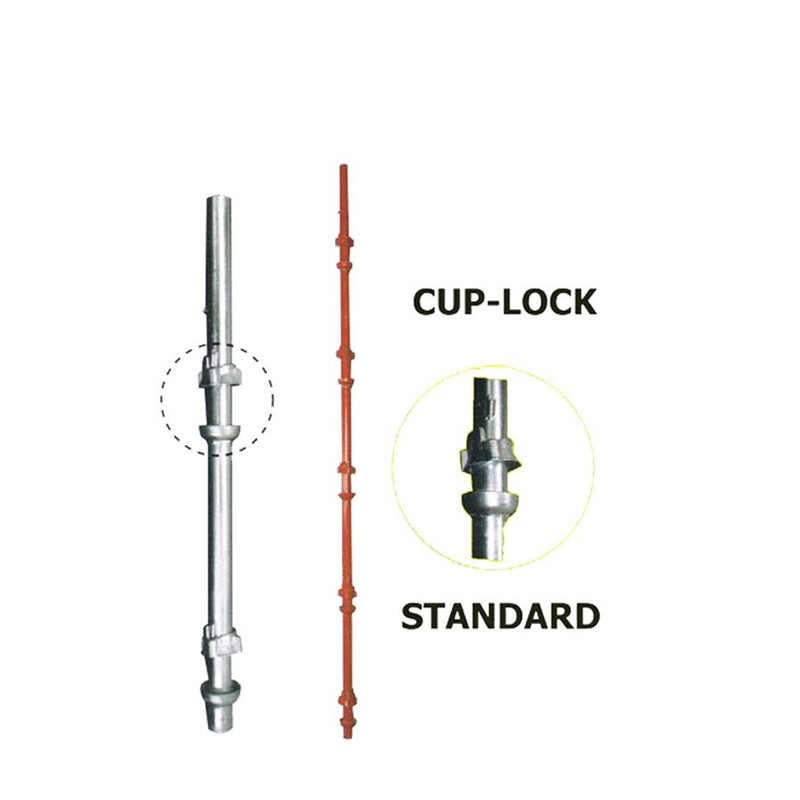

Cuplock scaffolding is a steel modular scaffolding system characterized by its unique node-point locking device. This device consists of a fixed lower cup welded at regular intervals on vertical standards and a movable upper cup that locks horizontal members (ledgers and transoms) into place with a simple rotation and hammer action. This design allows up to four horizontal components to be securely connected to a vertical standard in a single fastening action, making the system fast and easy to erect and dismantle.

Key Features of Cuplock Scaffolding

- Quick Assembly: The cup and blade locking mechanism eliminates the need for nuts, bolts, or wedges, enabling rapid erection.

- High Load Capacity: The system supports heavy working loads due to its robust steel construction and secure locking.

- Versatility: Suitable for various applications, including facade scaffolding, shoring, stair towers, circular scaffolds, loading towers, and mobile towers.

- Durability: Hot-dip galvanizing ensures corrosion resistance and long service life.

- Safety: The design promotes stability and safety on site, with comprehensive safety components available.

What Is a Cuplock Scaffolding Technical Manual?

A Cuplock scaffolding technical manual is a comprehensive guide published by manufacturers or suppliers that covers every aspect of the Cuplock scaffolding system. It typically includes:

- Component Identification and Specifications: Detailed descriptions and diagrams of core components such as standards, ledgers, transoms, braces, hop-up brackets, and accessories.

- Assembly Instructions: Step-by-step procedures for erecting, securing, and dismantling scaffolding safely and efficiently.

- Locking Mechanism Explanation: Visual and textual guidance on the unique cup locking procedure that ensures secure connections.

- Load Capacities and Limits: Safe working loads (SWL) for various components and configurations.

- Safety Guidelines: Health and safety protocols, site safety rules, and recommendations to prevent accidents.

- Design Guidance: Instructions for constructing different scaffold types including staircases, circular scaffolds, loading towers, and mobile towers.

- Maintenance and Inspection: Advice on scaffold inspection, maintenance, and quality control.

Example: Core Components Section

The manual explains that vertical standards are made from 48.3mm diameter steel tubes with fixed lower cups at 0.5m intervals and captive rotating top cups. Horizontal ledgers and transoms fit into these cups and are locked by rotating the upper cup, providing a positive and secure connection. Additional components like hop-up brackets and handrail posts are also described in detail.

Why Do You Need a Cuplock Scaffolding Technical Manual?

1. Ensures Safe and Correct Assembly

The manual provides precise instructions on how to assemble the Cuplock system correctly, minimizing the risk of unsafe practices. The unique locking mechanism requires understanding to ensure components are securely fixed. Following the manual reduces accidents and structural failures on site.

2. Improves Efficiency and Speed

By following the technical manual, workers can quickly learn the assembly process, reducing labor time and costs. The manual's clear guidance on component use and locking procedures helps avoid trial-and-error, speeding up scaffold erection and dismantling.

3. Facilitates Compliance with Regulations

Construction sites must comply with health and safety regulations. The manual includes safety standards and load limits that help ensure scaffolding meets legal requirements, protecting workers and employers from liabilities.

4. Supports Complex Scaffold Designs

For projects requiring specialized scaffolds like circular or loading towers, the manual offers design examples and technical data to build safe, stable structures tailored to specific needs.

5. Maintains Scaffold Integrity Over Time

Regular inspection and maintenance instructions in the manual help prolong scaffold life and maintain safety, especially for reusable Cuplock components with hot-dip galvanizing protection.

Detailed Components and Their Functions in Cuplock Scaffolding

Understanding the components detailed in the Cuplock scaffolding technical manual is crucial for proper scaffold construction. Here are some of the main parts:

Standards (Verticals)

These are the vertical tubes with fixed lower cups welded at 500mm intervals. They form the scaffold's backbone, supporting the horizontal members and bearing vertical loads. The rotating upper cup locks the horizontal members in place.

Ledgers (Horizontals)

Ledgers connect between standards horizontally, providing lateral support and creating working platforms. They fit into the lower cups of the standards and are locked by the upper cup.

Transoms

Transoms are horizontal members placed perpendicular to ledgers, supporting the scaffold boards. They also lock into the cup system, ensuring a rigid platform.

Braces

Diagonal braces enhance scaffold stability by preventing sway and racking. The manual specifies proper brace installation to maintain structural integrity.

Hop-Up Brackets

Hop-up brackets extend the working platform beyond the scaffold frame, allowing workers to access facades or other areas safely.

Accessories

Handrails, toe boards, base jacks, and ladder access components are also covered in the manual, each with detailed installation instructions.

Assembly Process Overview

The Cuplock scaffolding technical manual provides a step-by-step assembly process, typically including:

1. Base Preparation: Leveling the ground and placing base plates or adjustable jacks.

2. Erecting Standards: Positioning vertical standards and ensuring they are plumb.

3. Installing Ledgers and Transoms: Inserting horizontal members into the lower cups and locking with the rotating upper cups.

4. Adding Braces: Installing diagonal braces for lateral stability.

5. Planking and Decking: Placing scaffold boards on transoms to create safe working platforms.

6. Adding Safety Features: Installing guardrails, toe boards, and access ladders.

7. Inspection: Conducting thorough safety checks before use.

Safety Considerations Highlighted in the Manual

Safety is paramount in scaffolding work. The Cuplock scaffolding technical manual emphasizes:

- Load Limits: Never exceed the safe working load specified for each component or scaffold type.

- Proper Locking: Ensuring all cups are fully rotated and locked to prevent accidental dislodgement.

- Inspection: Regular inspections for damage, corrosion, or wear before and during use.

- Fall Protection: Use of guardrails, toe boards, and personal protective equipment (PPE).

- Training: Only trained personnel should erect, alter, or dismantle scaffolding.

- Weather Conditions: Avoid scaffold use in high winds or adverse weather unless properly secured.

Maintenance and Inspection

The manual stresses the importance of regular maintenance and inspection to ensure scaffold longevity and safety.

- Daily Inspections: Check for loose or damaged components, proper locking, and stability.

- Cleaning: Remove debris, mud, or ice that may cause slips or damage.

- Component Replacement: Replace any bent, cracked, or corroded parts immediately.

- Storage: Store components in dry, ventilated areas to prevent rust and damage.

Advantages of Using the Cuplock Scaffolding Technical Manual

- Standardizes Procedures: Ensures all workers follow the same safe and efficient assembly methods.

- Reduces Errors: Clear guidance minimizes mistakes that could lead to accidents or scaffold failure.

- Improves Communication: Serves as a reference point for supervisors, safety officers, and workers.

- Supports Training: Ideal for onboarding new workers and refresher training.

- Enhances Project Planning: Provides technical data for scaffold design, budgeting, and scheduling.

Conclusion

A Cuplock scaffolding technical manual is an indispensable resource for anyone involved in the erection, use, or management of Cuplock scaffolding systems. It ensures safety, efficiency, and compliance by providing detailed technical information, assembly instructions, and safety guidelines. The unique cup locking system that defines Cuplock scaffolding makes it faster and easier to assemble than traditional scaffolds, but only when used correctly as outlined in the technical manual. For construction professionals aiming to optimize scaffold use while maintaining the highest safety standards, this manual is essential.

FAQ

1. What is the unique feature of Cuplock scaffolding that distinguishes it from other systems?

Cuplock scaffolding's unique feature is its node-point locking device consisting of fixed lower cups and rotating upper cups that lock up to four horizontal components to a vertical standard in one action, enabling fast and secure assembly.

2. How does the Cuplock locking mechanism work?

The locking mechanism involves a fixed lower cup welded to the vertical standard and a movable upper cup that drops over the horizontal blade ends and rotates to lock them firmly in place, creating a positive connection without nuts or bolts.

3. What components are covered in a Cuplock scaffolding technical manual?

The manual covers core components such as vertical standards, ledgers, transoms, braces, hop-up brackets, handrail posts, and accessories, along with their specifications, assembly instructions, and safety guidelines.

4. Why is it important to follow the Cuplock scaffolding technical manual?

Following the manual ensures safe and correct assembly, compliance with safety regulations, efficient erection and dismantling, and proper maintenance, reducing risks and project delays.

5. Can Cuplock scaffolding be used for complex scaffold structures?

Yes, the system's versatility and the manual's design guidance allow construction of complex scaffolds such as stair towers, circular scaffolds, loading towers, and mobile towers tailored to specific project needs.

Citations:

[1] https://www.huennebeck.com/uploads/files/cuplok_system_scaffold_user_guide_en_2015-05-29.pdf

[2] https://www.scafom-rux.com/en/scaffolding-blog/beginner-s-guide-to-scaffolding-types-the-cuplock-modular-scaffold

[3] https://utmscaffold.en.made-in-china.com/product/GEPrmckyTIYf/China-1m-1-5m-2m-2-5m-3m-Steel-Cuplock-Standard-Scaffolding.html

[4] https://www.adtoscaffold.com/product/cuplock_scaffold.html

[5] https://www.youtube.com/watch?v=ojYR6MRAoEI

[6] https://scaffco.com/wp-content/uploads/2020/04/07-Cuplock-System.pdf

[7] https://www.youtube.com/watch?v=wBKilb9ALEY

[8] https://suncorpscaffolding.com/10-most-important-safety-tips-cup-lock-scaffolding/

[9] https://www.affixscaffolding.com/wp-content/uploads/2022/03/Affix-Cuplock-Manual.pdf

[10] https://scaffolding-solutions.com.cy/wp-content/uploads/2022/06/user_manual_cuplok_10-2006.pdf

[11] https://www.rscaffolding.com/product-detail/cuplock-scaffolding-standards/

[12] https://www.scaffolding-in-china.com/products/easy-used-cuplock-scaffolding-system-for-building-project

[13] https://www.youtube.com/watch?v=QSKy3RkmKs8

[14] https://www.arabianspar.com/blog/cuplock-scaffolding-system-in-saudi-arabia-trusted-quality/

[15] https://www.wm-scaffold.com/cuplock-scaffolding-standard.html

[16] https://www.adtomall.com/cuplock-scaffolding

[17] https://jumplyscaffolding.com/what-is-cuplock-scaffolding/

[18] https://cdn.prod.website-files.com/6723c4704dc317b68172e019/67366167981794e9ead61adf_40489856166.pdf

[19] https://rapid-scafform.com/cuplock-scaffold/

[20] https://www.seawayscaffold.com/Portals/0/Documents/manuals/Scaffold/Cup%20Lock%20Technical%20Manual.pdf

[21] https://aaitscaffold.com/wp-content/uploads/2024/02/Cuplock-Product-Manual-AAIT-24-01-2024.pdf

[22] https://www.scaffoldingsupplies.co.uk/our_products/2/index.phtml

[23] https://www.seawayscaffold.com/resources/locking-cup-modular-scaffold-technical-manual

[24] https://www.defenal.com/pdf/cuplock-scaffolding.pdf

[25] https://www.durascf.com/product/cuplock-scaffolding-standard/

[26] https://naafes.com/file/file_1605766727752372313.pdf

[27] https://www.diamondscaffolding.in/cuplock-scaffold-systems

[28] https://www.shutterstock.com/search/cup-lock-scaffolding

[29] https://www.pinterest.com/eng_ahmed_s3d/cuplock/

[30] https://www.pinterest.com/pin/cuplock-scaffolding--765189792951942087/

[31] https://www.youtube.com/watch?v=9Diq4cESCBg

[32] https://www.youtube.com/watch?v=-ScFRrK-FKo

[33] https://www.youtube.com/playlist?list=PLkSGhLyLYML9jWJTmw2JcwwMH9OUoRFsb

[34] https://www.scaffoldsales.com/cuplock-system

[35] https://www.youtube.com/watch?v=fnJw0xLZE5s

[36] https://www.huennebeck.com/uploads/files/cuplok_system_scaffold_user_guide_en_2015-05-29.pdf

[37] https://www.youtube.com/watch?v=2FbwLFj1aFY

[38] https://www.scaffolding-direct.co.uk/cuplock-scaffolding-system-ledger-horizontal-0-9m.aspx

[39] https://www.youtube.com/watch?v=3rbyXSf_MYE

[40] https://grsscaffolding.com/blog/scaffolding-safety-tips/

[41] http://forum.iosh.co.uk/posts/m717172-Cuplock-Scaffolding

[42] https://www.strongholdhire.com.au/cuplok-scaffolding-sydney-a-z-guide/

[43] https://www.sparsteel.com/Scaffolding-Safety-Faqs.html

[44] https://www.amirsons.com/blog/cuplock-system-maintenance-tips-for-longevity-and-performance.php

[45] https://shelterrc.com/what-is-the-standard-size-of-cuplock-scaffolding/

[46] https://www.totalcontec.com/portfolio-items/cuplock/

[47] https://aaitscaffold.com/blog/top-7-scaffolding-questions-with-answers/

[48] https://primesteeltech.co.in/cuplock-scaffolding-system-a-comprehensive-study.html