Content Menu

● Introduction to Scaffold Towers

● Key Components of a Scaffold Tower

● Types of Scaffold Towers

● How to Assemble a Scaffold Tower

● Advantages of Using Scaffold Towers

● Safety Guidelines for Scaffold Towers

● Common Applications of Scaffold Towers

● Additional Considerations When Using Scaffold Towers

● Innovations in Scaffold Tower Design

● Environmental and Regulatory Compliance

● Conclusion

● FAQ

>> 1. What is the difference between a scaffold tower and traditional scaffolding?

>> 2. Can anyone assemble or use a scaffold tower?

>> 3. Are scaffold towers safe to use?

>> 4. Can scaffold towers be used on uneven ground?

>> 5. Do I need a harness when working on a scaffold tower?

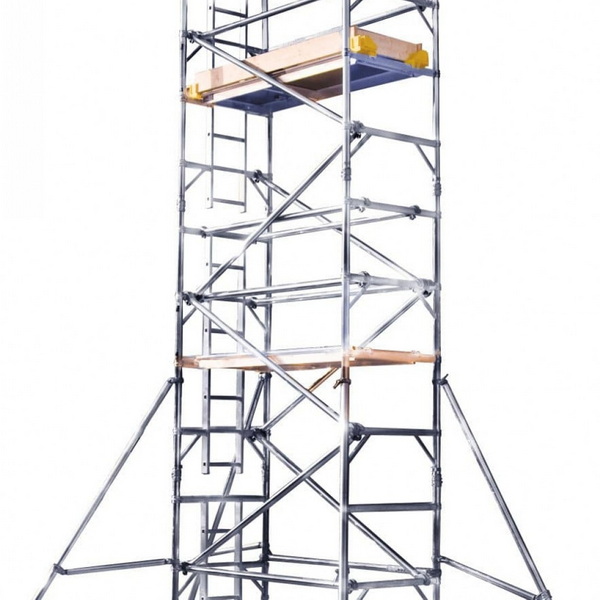

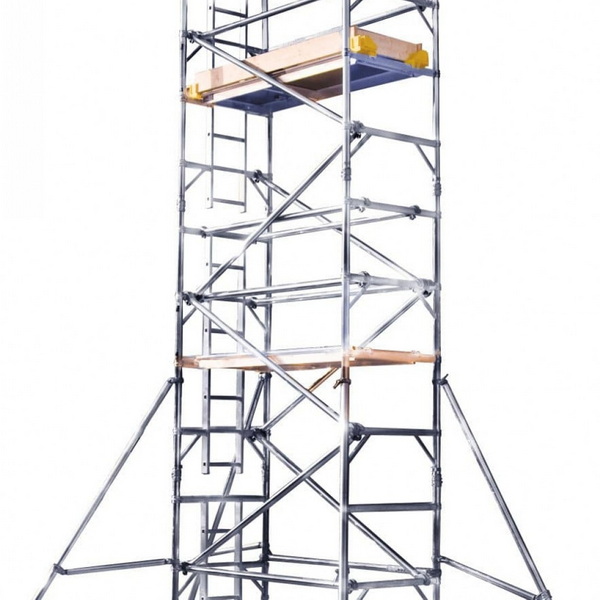

A scaffold tower is an essential piece of equipment in construction, maintenance, and various other industries where safe, elevated access is required. Unlike traditional scaffolding, a scaffold tower is a freestanding, modular structure designed for quick assembly, flexibility, and safety. This comprehensive guide will explore what a scaffold tower is, its types, components, uses, safety guidelines, and frequently asked questions.

Introduction to Scaffold Towers

A scaffold tower, also known as a tower scaffold or mobile access tower, is a temporary, elevated work platform constructed from prefabricated components. It is designed to provide a stable and secure platform for workers to perform tasks at height, such as painting, cleaning, repairs, and installation. Unlike traditional scaffolding, scaffold towers are freestanding and do not rely on the building structure for support, making them highly versatile and mobile.

Key Components of a Scaffold Tower

Understanding the components of a scaffold tower is crucial for safe assembly and use. The main parts include:

- Side Frames: Vertical supports that form the tower's structure.

- Braces: Horizontal and diagonal supports that provide stability.

- Platforms: The working surfaces where tasks are performed.

- Guardrails: Safety barriers to prevent falls.

- Toe Boards: Edges that prevent tools and materials from falling.

- Stabilizers/Outriggers: Extensions that increase the tower's footprint for added stability.

- Wheels or Casters: Allow mobility for mobile scaffold towers.

- Internal Ladder: Provides safe access to the working platform.

Types of Scaffold Towers

Scaffold towers come in various designs to suit different tasks and environments. Here are the most common types:

| Type | Description | Typical Use Cases |

| Standard Scaffold Tower | Modular, easy to assemble, stable platform | General construction, maintenance |

| Single Width Tower | Narrow, suitable for tight spaces | Indoor repairs, confined areas |

| Double Width Tower | Wider platform for multiple workers and equipment | Large projects, exterior work |

| Staircase Scaffold Tower | Designed for use on stairs with adjustable legs | Staircase painting, repairs |

| Advanced Guardrail (AGR) | Pre-fitted guardrails for enhanced safety | High-safety requirement projects |

| Linked Towers | Connected towers with bridging platforms | Large-scale repairs, continuous access |

| Rolling Scaffold Tower | Equipped with wheels for easy movement | Painting, cleaning, frequent relocation |

| Folding Scaffold Tower | Compact, foldable for easy transport | DIY, small-scale jobs |

| Cantilever Scaffold Tower | Platform extends over obstacles | Overhead work, access over obstacles |

| Large Deck Tower | Extra-large workspace, boxing ring style | Industrial, multi-worker projects |

| GRP Tower | Made from non-conductive fiberglass | Electrical, utilities, clean environments |

How to Assemble a Scaffold Tower

Assembling a scaffold tower requires careful attention to safety and manufacturer instructions. The process typically involves:

1. Clearing and leveling the area.

2. Assembling the base frame and locking wheels/casters.

3. Adding horizontal and diagonal braces for stability.

4. Installing the working platform and guardrails.

5. Securing toe boards and internal ladders.

6. Adding stabilizers or outriggers if necessary.

Advantages of Using Scaffold Towers

- Mobility: Easily moved to different locations, ideal for tasks requiring frequent repositioning.

- Quick Assembly: Prefabricated components allow for rapid setup and dismantling.

- Safety: Guardrails, toe boards, and stable platforms offer superior safety compared to ladders.

- Versatility: Suitable for indoor and outdoor use, on flat or slightly uneven surfaces.

- Cost-Effective: Reduces labor and time costs due to efficient assembly and adaptability.

Safety Guidelines for Scaffold Towers

Safety is paramount when working at height. Follow these essential guidelines:

- Set Up on Stable, Level Ground: Never assemble a tower on uneven or unstable surfaces.

- Use Correct Components: Only use manufacturer-approved parts.

- Inspect Before Use: Check for defects or missing parts before every use.

- Do Not Overload: Stay within the prescribed load limits for people and equipment.

- Work on Protected Platforms: Ensure guardrails and toe boards are in place.

- Follow Manufacturer's Instructions: Always adhere to the assembly and usage guidelines.

- Get Proper Training: Only trained personnel should erect, adjust, or dismantle scaffold towers.

- Comply with Standards: Follow relevant safety standards such as EN1004 for mobile access towers.

- Check Scaffold Tags: Only use towers with a green safety tag indicating they are safe for use.

Common Applications of Scaffold Towers

- Construction: Painting, plastering, bricklaying, facade repairs.

- Maintenance: Cleaning windows, repairing roofs, installing signage.

- Industrial: Warehousing, electrical work, HVAC installation.

- Events: Stage setup, lighting, decorations.

- DIY Projects: Home repairs, garden maintenance, interior painting.

Additional Considerations When Using Scaffold Towers

When planning to use scaffold towers, it is important to consider environmental factors such as wind speed and weather conditions, as these can affect the stability and safety of the tower. Always avoid using scaffold towers during strong winds or storms. Moreover, regular maintenance and cleaning of scaffold components help prolong their lifespan and ensure safety.

Innovations in Scaffold Tower Design

Recent advancements in scaffold tower technology include the integration of lightweight materials such as aluminum and fiberglass, which enhance portability without compromising strength. Some modern scaffold towers also feature modular designs that allow for quick customization to fit unique job site requirements. These innovations have made scaffold towers more adaptable to a wider range of environments and have improved both user safety and efficiency.

Environmental and Regulatory Compliance

Using scaffold towers in compliance with local regulations and environmental standards is crucial. Many regions require adherence to specific safety codes and certifications, such as OSHA standards in the United States or EN standards in Europe. Ensuring compliance not only promotes safety but also avoids legal penalties. Additionally, responsible disposal and recycling of scaffold components at the end of their life cycle contribute to environmental sustainability.

Conclusion

A scaffold tower is a highly versatile, safe, and efficient solution for working at height across a range of industries. Its modular design, ease of assembly, and mobility make it superior to traditional ladders and scaffolding in many scenarios. By following proper assembly procedures and safety guidelines, scaffold towers can significantly enhance productivity and reduce the risk of accidents on site.

FAQ

1. What is the difference between a scaffold tower and traditional scaffolding?

A scaffold tower is a freestanding, modular structure designed for quick assembly and mobility, while traditional scaffolding is a fixed structure that relies on the building for support and is typically used for larger, longer-term projects.

2. Can anyone assemble or use a scaffold tower?

No, only trained and competent individuals should assemble, adjust, or dismantle scaffold towers. Proper training and risk assessment are essential for safe use.

3. Are scaffold towers safe to use?

Yes, scaffold towers are safe when assembled correctly, used within load limits, and equipped with all necessary safety features like guardrails and toe boards. Regular inspections and adherence to safety standards are crucial.

4. Can scaffold towers be used on uneven ground?

Some scaffold towers have adjustable legs for use on slightly uneven surfaces, but they should not be used on slopes exceeding 5 degrees unless specifically designed for such conditions.

5. Do I need a harness when working on a scaffold tower?

If the scaffold tower is equipped with all safety features (guardrails, toe boards, outriggers, internal ladder), a harness is generally not required. However, standard PPE such as hard hats and high-visibility jackets should always be worn.