Content Menu

● What Is an Aluminum Telescoping Work Plank?

● Primary Uses of Aluminum Telescoping Work Planks

>> 1. Painting and Drywall Installation

>> 2. Plastering and Stucco Work

>> 3. Window Repairs and Installation

>> 4. Roofing and Exterior Maintenance

>> 5. General Construction and Renovation

● Popular Models and Their Specifications

● Benefits of Using Aluminum Telescoping Work Planks

>> Portability and Ease of Use

>> Versatility

>> Safety Features

>> Cost-Effectiveness

>> Durability

● How to Use an Aluminum Telescoping Work Plank Safely

● Maintenance Tips for Aluminum Telescoping Work Planks

● Advanced Features to Consider When Choosing a Telescoping Work Plank

● Environmental Impact and Sustainability

● Conclusion

● FAQ

>> 1. What are the primary uses of aluminum telescoping work planks?

>> 2. How do I ensure safety while using an aluminum telescoping plank?

>> 3. What factors should I consider when choosing an aluminum telescoping plank?

>> 4. Can aluminum telescoping planks be used outdoors?

>> 5. How do I maintain my aluminum telescoping plank?

An aluminum telescoping work plank is a versatile, adjustable platform commonly used in construction, maintenance, and DIY projects. Its unique telescoping design allows the plank to extend or retract to fit various working widths, making it an essential tool for professionals and homeowners alike. This article explores in detail the uses, features, benefits, and safety considerations of aluminum telescoping work planks.

What Is an Aluminum Telescoping Work Plank?

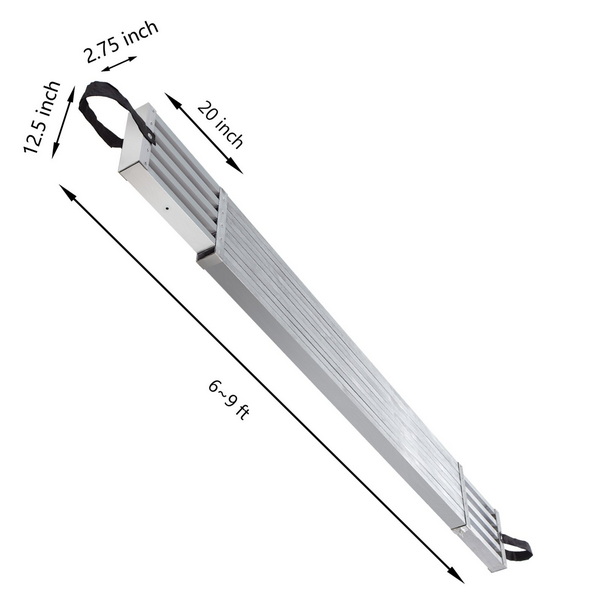

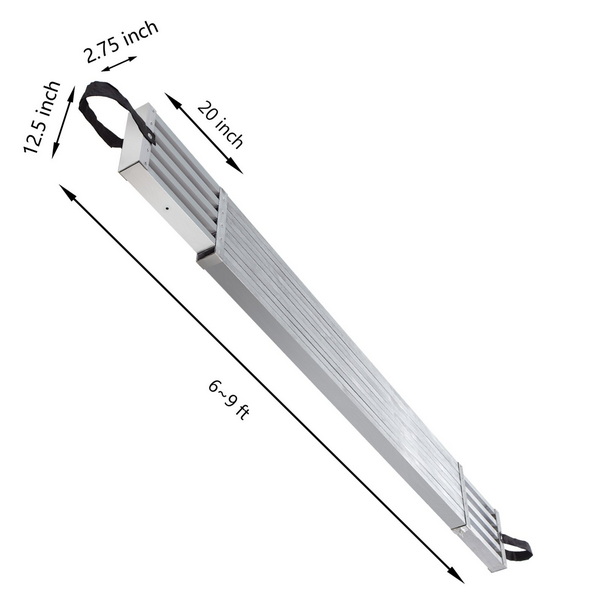

An aluminum telescoping work plank is a lightweight, durable plank made from corrosion-resistant aluminum that can extend in length to suit different job requirements. Unlike fixed-length planks, its telescoping feature allows users to adjust the length, typically in increments of one foot, to fit between ladders, scaffolding, or sawhorses.

Key Features Include:

- Adjustable Length: Common models extend from 6 to 9 feet, 8 to 13 feet, or even 10 to 17 feet.

- Lightweight Aluminum Construction: Easy to carry and maneuver on job sites.

- High Load Capacity: Ranges from 250 lbs to 500 lbs depending on the model.

- Anti-Slip Surface: Grooved or textured to provide secure footing.

- Locking Mechanisms: Secure the plank at the desired length for safety.

- Compatibility: Designed for use with ladders, trestles, and scaffolding systems.

Primary Uses of Aluminum Telescoping Work Planks

1. Painting and Drywall Installation

Aluminum telescoping work planks provide a stable, adjustable platform for painters and drywall installers to work efficiently across wide walls or ceilings without constantly repositioning ladders. The telescoping feature allows the plank to fit snugly between supports, reducing setup time and improving workflow.

2. Plastering and Stucco Work

The plank's adjustable length makes it ideal for plastering or stucco application on walls of varying widths, allowing continuous movement and reducing the need for frequent repositioning. The sturdy aluminum construction supports the weight of workers and materials safely.

3. Window Repairs and Installation

Technicians use these planks to safely access wide window spans, adjusting the plank length to fit precisely between supports. This flexibility is especially valuable in commercial buildings where window widths vary significantly.

4. Roofing and Exterior Maintenance

The lightweight, corrosion-resistant aluminum construction is well-suited for roofing tasks, gutter cleaning, and exterior building maintenance, especially in outdoor environments. The plank's adjustability helps accommodate different roof widths and angles.

5. General Construction and Renovation

These planks serve as temporary walkways, staging areas for tools, or platforms for various elevated tasks, enhancing productivity and safety. Their portability and adjustability make them a preferred choice for many contractors.

Popular Models and Their Specifications

| Model |

Extension Range |

Load Capacity |

Weight |

Material |

| MetalTech Telescoping |

8 ft to 13 ft |

250 lbs |

41 lbs |

Aluminum |

| Little Giant Plank |

6-9, 8-13, 9-15 ft |

Up to 500 lbs |

32.5 lbs |

Aircraft-grade Aluminum |

| Vevor Telescoping |

9 ft to 15 ft |

440 lbs |

~40 lbs |

Tubular Aluminum |

Benefits of Using Aluminum Telescoping Work Planks

Portability and Ease of Use

The lightweight aluminum construction and telescoping design make these planks easy to transport, set up, and adjust on-site, saving time and effort. This portability is especially beneficial for projects requiring frequent relocation of work platforms.

Versatility

Adjustable length allows one plank to replace multiple fixed-length planks, fitting various scaffold widths and ladder setups. This versatility reduces equipment costs and storage space requirements.

Safety Features

Anti-slip surfaces and secure locking mechanisms reduce the risk of slips and falls, providing a stable work platform. The locking systems ensure the plank remains firmly at the chosen length during use.

Cost-Effectiveness

By reducing the need for multiple planks and complex scaffolding, telescoping planks offer significant cost savings. Their durability also means fewer replacements over time.

Durability

Aluminum's corrosion resistance and robust construction ensure a long service life, even with frequent outdoor use. This makes aluminum telescoping work planks ideal for harsh environments.

How to Use an Aluminum Telescoping Work Plank Safely

- Set Up on Level Surfaces: Always position ladders or trestles on stable, level ground to prevent tipping.

- Secure Locking: Ensure locking pins or wing bolts are fully engaged before stepping on the plank.

- Do Not Overextend: Never extend the plank beyond the manufacturer's recommended maximum length to avoid instability.

- Check Load Capacity: Do not exceed the rated weight limit, including tools and materials.

- Use with Compatible Equipment: Confirm the plank fits securely with your ladders or scaffold frames.

- Wear Safety Gear: Use appropriate personal protective equipment (PPE) such as non-slip shoes and harnesses if working at height.

Maintenance Tips for Aluminum Telescoping Work Planks

- Regular Cleaning: Remove dirt, paint, and debris to maintain the anti-slip surface and prevent damage.

- Inspect Before Use: Check for dents, cracks, or damaged locking mechanisms to ensure safety.

- Lubricate Moving Parts: Apply light lubricant to sliding sections to ensure smooth operation.

- Store Properly: Keep the plank in a dry, covered area to prevent corrosion and damage.

- Replace Damaged Parts: Promptly repair or replace worn components to maintain safety.

Advanced Features to Consider When Choosing a Telescoping Work Plank

- Lockless Extension Systems: Some models offer lockless designs for quicker length adjustments.

- Wider Platforms: Planks with wider surfaces provide more comfortable working space.

- Integrated Hooks or Straps: Additional securing features improve stability on ladders.

- Higher Load Ratings: For two-person use or heavy equipment, select planks with higher weight capacities.

- Weather-Resistant Finishes: Anodized or powder-coated aluminum resists corrosion better in harsh environments.

Environmental Impact and Sustainability

Aluminum telescoping work planks contribute positively to sustainability efforts. Aluminum is highly recyclable, and the durable nature of these planks reduces the need for frequent replacements, minimizing waste. Additionally, their lightweight design reduces transportation fuel consumption, lowering carbon emissions associated with logistics.

Conclusion

An aluminum telescoping work plank is an indispensable tool for a variety of tasks in construction, maintenance, and home improvement. Its adjustable length, lightweight design, and safety features make it highly versatile and efficient, reducing setup time and increasing productivity. Whether you are painting walls, installing drywall, repairing windows, or performing exterior maintenance, these planks provide a stable and secure platform that adapts to your needs. With proper use and maintenance, aluminum telescoping work planks offer long-lasting performance and excellent value.

FAQ

1. What are the primary uses of aluminum telescoping work planks?

They are mainly used for painting, drywall installation, plastering, window repairs, roofing, and general maintenance tasks that require a stable elevated platform.

2. How do I ensure safety while using an aluminum telescoping plank?

Always lock the plank securely at the desired length, use it on level surfaces, do not exceed weight limits, and wear appropriate safety gear.

3. What factors should I consider when choosing an aluminum telescoping plank?

Consider the required extension range, load capacity, compatibility with your ladders or scaffolds, safety features, and material quality.

4. Can aluminum telescoping planks be used outdoors?

Yes, their corrosion-resistant aluminum construction and weather-resistant finishes make them suitable for outdoor use.

5. How do I maintain my aluminum telescoping plank?

Regularly clean and inspect the plank, lubricate moving parts, store it in a dry place, and promptly repair or replace any damaged components.