Content Menu

● Introduction to Cuplock Scaffolding

● Key Components of Cuplock Scaffolding

● Advantages of Cuplock Scaffolding

● Applications of Cuplock Scaffolding

● How to Assemble Cuplock Scaffolding

● Safety Considerations

● Maintenance of Cuplock Scaffolding

● Cost Considerations

● Future Trends in Scaffolding Systems

● Conclusion

● FAQ

>> 1. What is cuplock scaffolding?

>> 2. What are the benefits of using cuplock scaffolding?

>> 3. How does cuplock scaffolding compare to traditional scaffolding?

>> 4. Is cuplock scaffolding safe?

>> 5. Can cuplock scaffolding be used in adverse weather conditions?

Cuplock scaffolding is a widely recognized modular scaffolding system that is extensively used in construction and maintenance projects. It is characterized by its unique locking mechanism, which utilizes metal cups to securely connect horizontal and vertical components. This innovative design enhances the speed and efficiency of scaffold assembly, making it a preferred choice for various construction applications.

Introduction to Cuplock Scaffolding

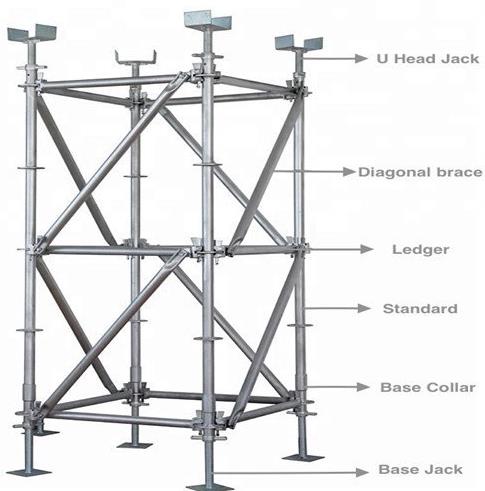

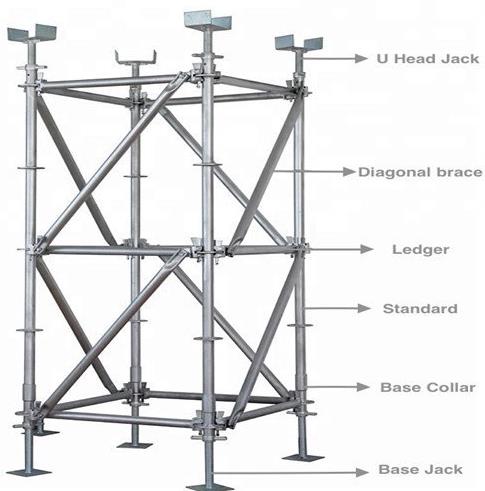

Cuplock scaffolding consists of vertical standards, horizontal ledgers, and a series of cups that act as connection points. The system allows for quick assembly and disassembly, making it ideal for projects that require temporary access solutions. Its robust design ensures stability and safety for workers at height, which is critical in the construction industry.

Key Components of Cuplock Scaffolding

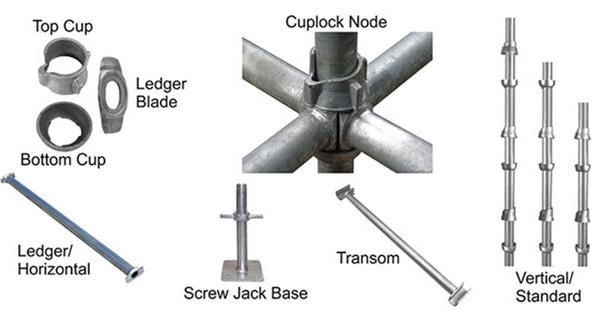

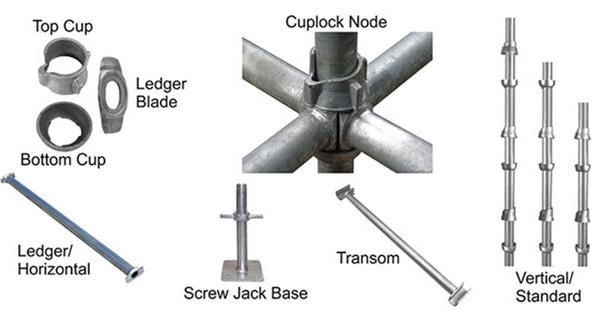

- Vertical Standards: These are the main load-bearing elements of the scaffolding system. They are typically made from high-grade steel and are equipped with fixed lower cups at regular intervals (usually 0.5 meters apart).

- Horizontal Ledgers: These components connect between vertical standards and provide the framework for supporting workers and materials.

- Cups: The unique feature of the cuplock system is its cup mechanism. Each vertical standard has a bottom cup welded to it, while a movable top cup can lock over the horizontal ledgers, securing them in place.

- Transoms and Braces: Diagonal braces enhance stability by preventing lateral movement, while transoms provide additional support for scaffold boards.

Advantages of Cuplock Scaffolding

Cuplock scaffolding offers several advantages that make it a popular choice among contractors:

- Quick Assembly and Disassembly: The unique node-point locking system allows for rapid connection of multiple components without the need for loose clips or bolts, significantly reducing labor time.

- High Load-Bearing Capacity: Designed to support heavy loads, cuplock scaffolding is suitable for various construction tasks, including high-rise buildings and industrial projects.

- Versatility: The modular nature of cuplock scaffolding means it can be adapted to different shapes and sizes, accommodating various project requirements.

- Safety Features: The secure locking mechanism minimizes the risk of accidental disconnections, ensuring a stable working platform for laborers.

Applications of Cuplock Scaffolding

Cuplock scaffolding is utilized in a wide range of applications:

- Building Construction: Provides safe access for workers during the construction of residential and commercial buildings.

- Industrial Maintenance: Ideal for maintenance tasks in factories, power plants, and refineries where access to elevated areas is required.

- Bridge Construction: Offers stable support systems for bridge construction and maintenance projects.

- Event Staging: Used to create temporary structures for events such as concerts and festivals.

How to Assemble Cuplock Scaffolding

Assembling cuplock scaffolding involves several steps:

1. Prepare the Site: Ensure the area is clear of debris and that the ground is stable.

2. Lay Base Plates: Position base plates on the ground where vertical standards will be placed. This distributes weight evenly.

3. Install Vertical Standards: Insert vertical standards into the base plates, ensuring they are plumb.

4. Attach Bottom Cups: Secure bottom cups onto the standards to hold horizontal ledgers.

5. Insert Horizontal Ledgers: Place horizontal ledgers into the bottom cups.

6. Install Top Cups: Attach top cups to secure the upper ends of the horizontal ledgers.

7. Add Diagonal Braces: Install diagonal braces to enhance stability.

8. Place Scaffold Boards: Lay scaffold boards across the ledgers to create a working platform.

Safety Considerations

Safety is paramount when using cuplock scaffolding. Here are key safety measures:

- Regular Inspections: Conduct frequent inspections of all components before use to ensure structural integrity.

- Load Limits: Adhere to specified load limits to prevent overloading the scaffold system.

- Guardrails and Safety Nets: Install guardrails at all levels to prevent falls.

- Training: Ensure all workers are trained in proper assembly techniques and safety protocols.

Maintenance of Cuplock Scaffolding

Regular maintenance of cuplock scaffolding is crucial to ensure its longevity and safety. Here are some maintenance tips:

- Routine Checks: Inspect all components regularly for signs of wear or damage. Look for rust on steel parts or deformation in any component due to excessive load or impact.

- Cleaning Procedures: Keep all parts clean from debris, dirt, or any other materials that may affect their functionality or safety. This includes ensuring that locking mechanisms are free from obstructions.

- Storage Conditions: Store scaffolding components in a dry environment when not in use to prevent corrosion or damage from weather elements.

- Replacement Parts: Replace any damaged or worn-out parts immediately rather than trying to repair them on-site, as this can compromise safety.

Cost Considerations

When considering cuplock scaffolding for your project, it's essential to evaluate costs effectively:

- Initial Investment vs. Long-Term Savings: While cuplock systems may have a higher initial cost compared to traditional scaffolding systems, their durability and ease of assembly often lead to significant savings in labor costs over time.

- Rental vs. Purchase Options: Depending on project duration and frequency of use, consider whether renting or purchasing cuplock scaffolding makes more financial sense. Rental options can be beneficial for short-term projects without long-term storage concerns.

- Insurance Costs: Factor in insurance costs associated with using scaffolding systems on-site. Properly maintained systems may lead to lower insurance premiums due to reduced risk profiles.

Future Trends in Scaffolding Systems

The future of scaffolding systems like cuplock is likely shaped by advancements in technology:

- Smart Scaffolding Solutions: The integration of IoT (Internet of Things) technology could lead to smart scaffolds equipped with sensors that monitor structural integrity in real-time, alerting users about potential issues before they become critical.

- Sustainability Practices: As environmental concerns grow, manufacturers may focus on producing scaffolding from sustainable materials or implementing recycling programs for old equipment.

- Enhanced Safety Features: Innovations such as automatic locking mechanisms or integrated fall protection systems could further enhance worker safety while using cuplock scaffolding.

Conclusion

The cuplock scaffolding system represents a significant advancement in temporary access solutions within the construction industry. Its efficient assembly process, high load-bearing capacity, versatility, and robust safety features make it an invaluable tool for contractors worldwide. By adhering to safety guidelines and utilizing this innovative system effectively, construction projects can proceed with enhanced productivity while ensuring worker safety remains a top priority.

FAQ

1. What is cuplock scaffolding?

Cuplock scaffolding is a modular scaffolding system characterized by its cup locking mechanism that connects horizontal ledgers to vertical standards without using loose clips or bolts.

2. What are the benefits of using cuplock scaffolding?

The benefits include quick assembly/disassembly, high load-bearing capacity, versatility in application, enhanced safety features, and minimal maintenance requirements.

3. How does cuplock scaffolding compare to traditional scaffolding?

Cuplock scaffolding offers faster assembly times due to its unique locking mechanism, greater stability due to fewer loose parts, and better adaptability to various project needs compared to traditional systems.

4. Is cuplock scaffolding safe?

Yes, when assembled correctly following safety guidelines, cuplock scaffolding provides a stable working platform with reduced risks of accidents due to its secure locking mechanism.

5. Can cuplock scaffolding be used in adverse weather conditions?

While cuplock scaffolding is robust, extreme weather conditions may affect its stability; therefore, work should be halted during severe weather events until conditions improve.