Content Menu

● Components of Fixed Clamp Scaffolding

● Assembly Process

● Applications of Fixed Clamp Scaffolding

● Safety Practices

● Advantages and Disadvantages

● Conclusion

● FAQ

>> 1. What is the primary advantage of using fixed clamp scaffolding over other types?

>> 2. How often should fixed clamp scaffolding be inspected?

>> 3. What type of training is required for workers who erect and dismantle fixed clamp scaffolding?

>> 4. Can fixed clamp scaffolding be used in all weather conditions?

>> 5. What are the key components that must be included in a fixed clamp scaffolding system to ensure safety?

● Citations:

Fixed clamp scaffolding is a widely used system in the construction industry, valued for its strength, stability, and adaptability. Unlike modular or frame scaffolding, fixed clamp scaffolding (also known as tube and clamp or tube and coupler scaffolding) relies on individual tubes connected by various types of clamps or couplers. This method allows for a highly customizable scaffolding structure suitable for complex building shapes and demanding load requirements. This article provides an in-depth look at fixed clamp scaffolding, covering its components, assembly, applications, safety practices, advantages, and disadvantages.

Components of Fixed Clamp Scaffolding

The versatility of fixed clamp scaffolding comes from its basic yet robust components:

- Steel Tubes: These are the primary structural members. Scaffold tubes are typically made of high-strength steel and come in various lengths to suit different scaffolding configurations.

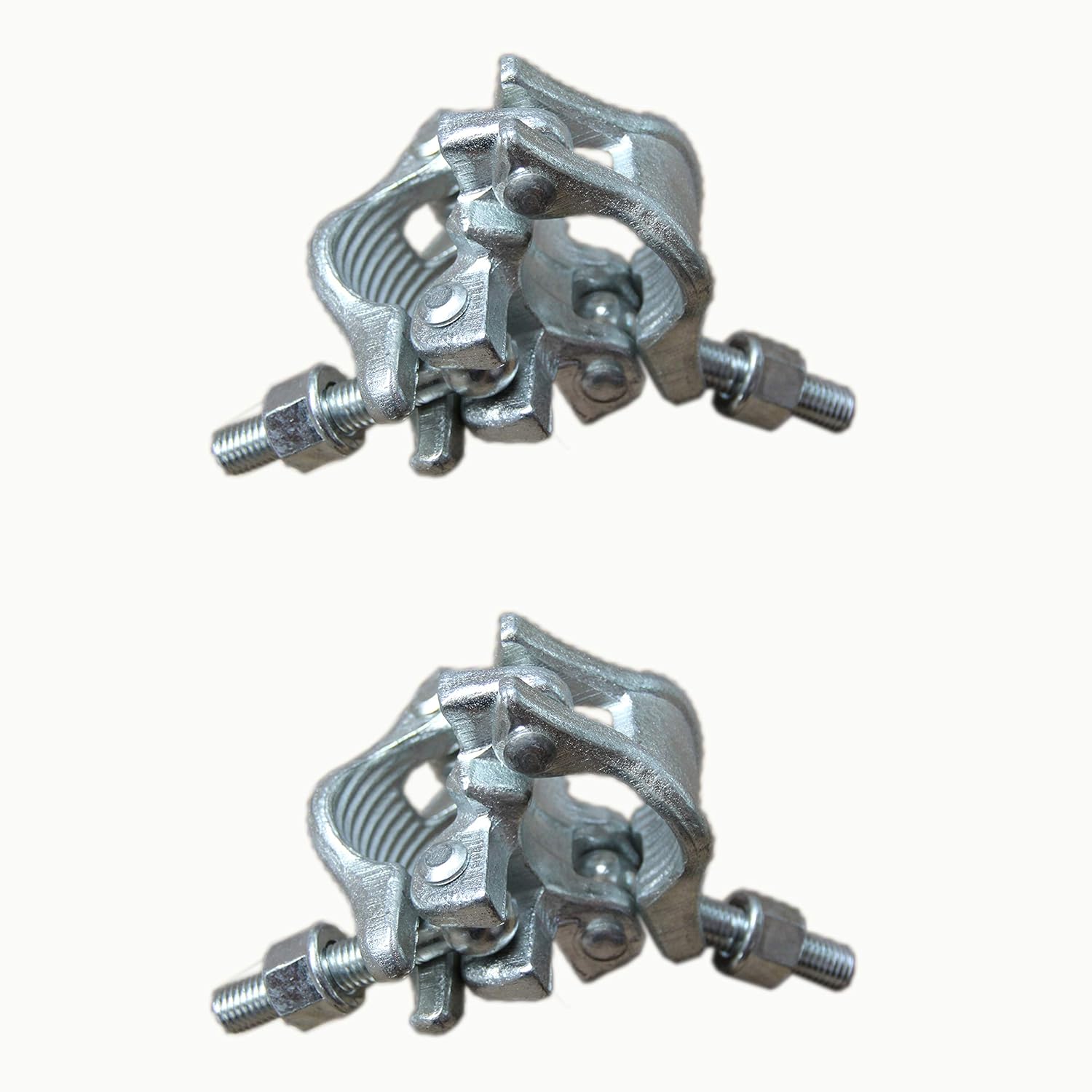

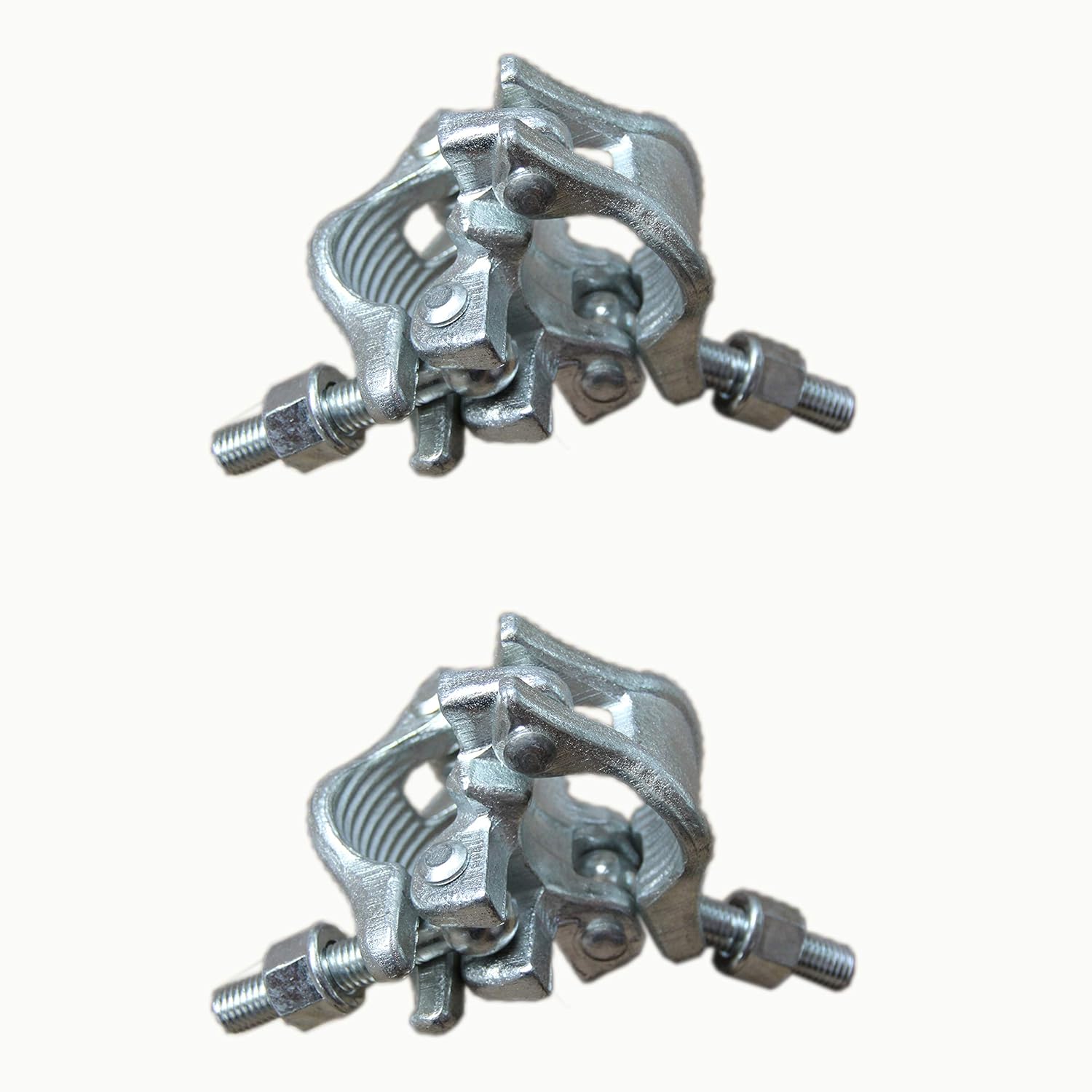

- Fixed Clamps (Right Angle Couplers): These connect tubes at a 90-degree angle, providing a rigid connection for load-bearing components. They are essential for connecting ledgers to standards and transoms to ledgers.

- Swivel Clamps (Swivel Couplers): Unlike fixed clamps, swivel clamps can connect tubes at any angle. This is crucial for bracing and creating angled supports.

- Base Plates: These provide a flat, stable base for the scaffolding standards and distribute the load evenly to the ground. Adjustable base plates are often used to accommodate uneven surfaces.

- Standards (Uprights): These are the vertical tubes that transfer the load to the ground. They are the main support for the entire structure.

- Ledgers (Runners): These are horizontal tubes running along the length of the scaffold, connected to the standards. They provide horizontal support and connect the standards.

- Transoms (Crossbeams): These are horizontal tubes placed between the ledgers, supporting the working platform.

- Braces: Diagonal braces are crucial for providing stability to the scaffolding structure. They prevent swaying and buckling.

- Platforms (Boards or Decks): These create the working surface of the scaffold. They can be made of wood, steel, or aluminum.

- Toe Boards: Installed along the edges of the platforms, toe boards prevent tools and materials from falling off.

- Guardrails: These provide a safety barrier to prevent falls from the platform. They typically consist of a top rail, mid-rail, and sometimes a bottom rail.

Assembly Process

Assembling fixed clamp scaffolding requires skilled labor and a thorough understanding of scaffolding principles. The general process involves:

1. Planning and Preparation: Assess the site, determine the required scaffolding configuration, and gather the necessary components.

2. Base Setup: Place base plates on a firm, level surface. Use adjustable base plates to compensate for uneven ground.

3. Erecting Standards: Position the standards on the base plates and ensure they are plumb.

4. Attaching Ledgers: Connect ledgers to the standards using fixed clamps at appropriate intervals.

5. Installing Transoms: Place transoms between the ledgers, using fixed clamps to secure them.

6. Adding Braces: Install diagonal braces to the standards and ledgers using swivel clamps to provide stability.

7. Placing Platforms: Lay the platforms on the transoms, ensuring they are securely in place.

8. Installing Safety Features: Install toe boards and guardrails to protect workers from falls.

9. Inspection: A qualified person should inspect the scaffolding to ensure it is erected correctly and safely.

Applications of Fixed Clamp Scaffolding

Fixed clamp scaffolding is highly versatile and can be used in various construction and maintenance applications, including:

- Construction of buildings: Providing access for bricklaying, plastering, painting, and other construction tasks.

- Renovation and repair work: Allowing workers to reach high areas for repairs, painting, and cleaning.

- Shipbuilding and maintenance: Offering a stable platform for workers to perform tasks on ships.

- Industrial maintenance: Providing access to machinery and equipment for maintenance and repair in factories and plants.

- Bridge construction and repair: Enabling workers to reach all areas of a bridge for construction, inspection, and maintenance.

Safety Practices

Working with fixed clamp scaffolding involves potential risks. Strict adherence to safety practices is essential to prevent accidents and injuries:

- Proper Training: Workers must be properly trained in scaffolding erection, use, and dismantling.

- Regular Inspections: Scaffolding should be inspected regularly by a competent person to identify and address any defects or hazards.

- Load Limits: Never exceed the maximum load capacity of the scaffolding.

- Fall Protection: Workers should always use appropriate fall protection equipment, such as safety harnesses and lanyards.

- Weather Conditions: Avoid working on scaffolding in high winds, storms, or other adverse weather conditions.

- Safe Access: Use ladders or stairways to access the scaffolding, and never climb on the scaffolding structure itself.

- Competent Supervision: Scaffolding work should be supervised by a competent person who can ensure that safety procedures are followed.

Advantages and Disadvantages

Fixed clamp scaffolding offers several advantages:

- Versatility: It can be adapted to various shapes and sizes, making it suitable for complex structures.

- Strength: It can support heavy loads, making it ideal for demanding construction tasks.

- Flexibility: Components can be easily added or removed to modify the scaffolding as needed.

However, it also has some disadvantages:

- Labor Intensive: Erection and dismantling require skilled labor and can be time-consuming.

- Component Management: Requires careful management of individual components to avoid loss or damage.

- Complexity: Can be more complex to design and erect than modular scaffolding systems.

Conclusion

Fixed clamp scaffolding remains a reliable and adaptable solution in the construction industry. Its strength, flexibility, and versatility make it suitable for a wide range of applications. By understanding its components, assembly process, safety practices, advantages, and disadvantages, construction professionals can effectively utilize fixed clamp scaffolding to create safe and efficient working platforms.

FAQ

1. What is the primary advantage of using fixed clamp scaffolding over other types?

The primary advantage of fixed clamp scaffolding is its versatility. It can be adapted to fit complex shapes and spaces where modular scaffolding systems might not be suitable.

2. How often should fixed clamp scaffolding be inspected?

Fixed clamp scaffolding should be inspected regularly by a competent person, ideally before each work shift and after any event that could compromise its stability, such as high winds or heavy loads.

3. What type of training is required for workers who erect and dismantle fixed clamp scaffolding?

Workers should receive comprehensive training that covers the safe erection, dismantling, alteration, moving, operation, repair, maintenance, and inspection of scaffolding. This training should be provided by a qualified instructor and comply with relevant safety regulations.

4. Can fixed clamp scaffolding be used in all weather conditions?

No, fixed clamp scaffolding should not be used in all weather conditions. Work on scaffolding should be avoided during high winds, storms, or other adverse weather conditions that could compromise safety.

5. What are the key components that must be included in a fixed clamp scaffolding system to ensure safety?

The key safety components include base plates, standards, ledgers, transoms, braces, platforms with toe boards, and guardrails. Additionally, workers should use appropriate fall protection equipment, such as safety harnesses and lanyards.

Citations:

[1] https://pplx-res.cloudinary.com/image/upload/v1743682529/user_uploads/qfoOdWuowKnQBuf/image.jpg

[2] https://pplx-res.cloudinary.com/image/upload/v1743682532/user_uploads/EiZOFLWQPzYYgSy/image.jpg