Content Menu

● Understanding Ringlock Scaffolding

● Key Features of Ringlock Scaffolding

● Components of Ringlock Scaffolding

● Advantages of Using Ringlock Scaffolding

● Applications of Ringlock Scaffolding

● Installation Process

● Maintenance of Ringlock Scaffolding

● Safety Considerations

● Conclusion

● FAQ

>> 1. What is the primary advantage of using Ringlock scaffolding over traditional systems?

>> 2. Can Ringlock scaffolding be used in adverse weather conditions?

>> 3. How does Ringlock scaffolding ensure safety on-site?

>> 4. Is training required to install Ringlock scaffolding?

>> 5. What types of projects benefit most from using Ringlock scaffolding?

Ringlock scaffolding is a modern modular scaffolding system that has gained immense popularity in the construction industry due to its versatility, efficiency, and safety features. This article delves into the intricacies of the Ringlock system, exploring its components, advantages, applications, installation processes, and much more.

Understanding Ringlock Scaffolding

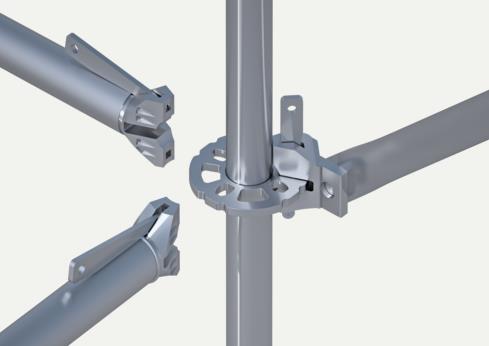

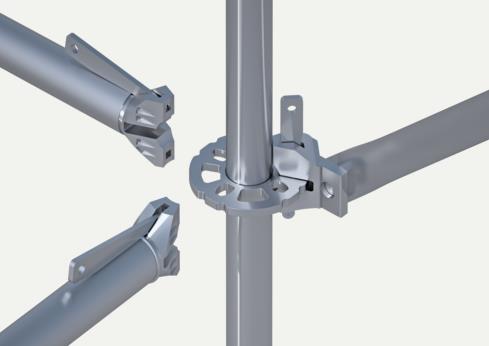

Ringlock scaffolding is characterized by its unique interlocking design, which utilizes a series of vertical standards and horizontal ledgers connected by rosettes. These rosettes allow for multiple connection points, providing flexibility in creating various scaffold configurations. The system is designed for quick assembly and dismantling, making it ideal for projects requiring rapid setup.

Key Features of Ringlock Scaffolding

- Modular Design: The Ringlock system consists of prefabricated components that can be easily assembled on-site. This modular approach allows for customization based on project requirements.

- Interlocking Mechanism: The rosette design enables multiple connections (up to eight) at different angles, facilitating complex structures such as curves and corners.

- High Load Capacity: Ringlock scaffolding can support substantial loads, making it suitable for heavy-duty applications in construction and industrial settings.

- Corrosion Resistance: Most Ringlock scaffolding systems are hot-dip galvanized to prevent rust and extend the lifespan of the components.

Components of Ringlock Scaffolding

The Ringlock system comprises several essential components:

- Vertical Standards: These are the main upright supports that form the framework of the scaffold. They often feature rosettes at regular intervals (typically every 500mm) for connecting horizontal ledgers and diagonal braces.

- Horizontal Ledgers: These are placed horizontally between vertical standards to provide stability and support for working platforms.

- Diagonal Braces: Used to enhance the structural integrity of the scaffold by preventing lateral movement.

- Base Plates and Jacks: Base plates provide a stable foundation for the scaffold, while jacks allow for height adjustments.

- Scaffold Planks: These are used as walking surfaces on the scaffold.

Advantages of Using Ringlock Scaffolding

1. Speed of Assembly: The design allows for quick erection with minimal tools required—often just a hammer is sufficient.

2. Versatility: The ability to create various configurations makes it suitable for a wide range of applications, from residential buildings to industrial projects.

3. Cost Efficiency: Fewer components mean reduced labor costs and quicker project turnaround times.

4. Safety Features: The interlocking design minimizes loose parts, reducing the risk of accidents on-site.

5. Adaptability: The system can be easily modified or expanded as project needs change.

6. Durability: The materials used in Ringlock scaffolding are designed to withstand harsh environmental conditions, ensuring longevity even with frequent use.

7. Ease of Transport: Due to its modular nature, transporting Ringlock scaffolding is more efficient than traditional systems, as it takes up less space when disassembled.

8. Reduced Labor Intensity: The ease of assembly reduces the physical strain on workers compared to more complex scaffolding systems.

Applications of Ringlock Scaffolding

Ringlock scaffolding is widely used across various sectors:

- Construction Sites: Ideal for both residential and commercial buildings due to its adaptability to different heights and shapes.

- Industrial Projects: Commonly utilized in factories, refineries, and power plants where heavy loads must be supported.

- Infrastructure Works: Suitable for bridge construction, maintenance tasks, and other infrastructure projects requiring robust support structures.

- Event Setup: Used in temporary structures such as grandstands or staging areas for events.

- Maintenance Work: Frequently employed in maintenance activities where access to elevated areas is necessary without permanent installation.

Installation Process

The installation of Ringlock scaffolding involves several straightforward steps:

1. Preparation: Assess the site and determine the required dimensions for the scaffold structure. Ensure that all components are available and in good condition before starting assembly.

2. Setting Up Base Plates: Position base plates or jacks at designated locations to ensure stability. It's crucial that these are level to prevent any wobbling once assembled.

3. Erecting Vertical Standards: Insert vertical standards into the base plates, ensuring they are plumb and secure. This step is vital as it sets the foundation for the entire structure.

4. Attaching Horizontal Ledgers: Connect horizontal ledgers to the vertical standards using the rosette connections. Ensure that these are locked in securely to prevent any movement during use.

5. Adding Diagonal Braces: Install diagonal braces to enhance stability, locking them into place with wedge pins. This will help prevent swaying or collapsing under load.

6. Placing Scaffold Planks: Lay planks across the ledgers to create a working surface. Ensure that these planks fit snugly against each other with no gaps that could pose a tripping hazard.

7. Final Checks: Inspect the entire structure for stability and security before use. It's essential to conduct a thorough inspection after assembly but also periodically during use, especially if heavy loads are applied or if conditions change (like weather).

Maintenance of Ringlock Scaffolding

To ensure safety and longevity, regular maintenance of Ringlock scaffolding is essential:

- Inspection Before Use: Always check for any signs of wear or damage before each use. Look specifically at connection points and load-bearing components.

- Cleaning Components: Remove dirt or debris from components regularly to prevent corrosion or weakening over time.

- Storage Practices: When not in use, store components in a dry area away from direct sunlight or harsh weather conditions to prolong their lifespan.

Safety Considerations

While Ringlock scaffolding is designed with safety features, adhering to best practices is crucial:

- Always ensure that all workers involved in assembly have received proper training specific to Ringlock systems.

- Use personal protective equipment (PPE) such as helmets, gloves, and harnesses when working at heights.

- Establish clear communication among team members during assembly and disassembly processes.

- Implement regular safety audits on-site to identify potential hazards related to scaffolding use.

Conclusion

Ringlock scaffolding stands out as a highly efficient and adaptable solution for various construction needs. Its modular design allows for quick assembly while ensuring safety and stability under heavy loads. As construction demands evolve, the versatility of Ringlock scaffolding positions it as a preferred choice among contractors worldwide.

FAQ

1. What is the primary advantage of using Ringlock scaffolding over traditional systems?

Ringlock scaffolding offers faster assembly times due to its modular design and fewer components, resulting in lower labor costs compared to traditional systems like tube and clamp scaffolding.

2. Can Ringlock scaffolding be used in adverse weather conditions?

Yes, the hot-dip galvanized finish provides corrosion resistance, making it suitable for outdoor use even in harsh weather conditions.

3. How does Ringlock scaffolding ensure safety on-site?

The interlocking mechanism reduces loose parts that could fall or become dislodged during use, significantly lowering accident risks associated with scaffolding work.

4. Is training required to install Ringlock scaffolding?

While basic knowledge of scaffold assembly is beneficial, specific training on using Ringlock systems can enhance safety and efficiency during installation.

5. What types of projects benefit most from using Ringlock scaffolding?

Ringlock scaffolding is versatile enough for various applications including residential construction, industrial maintenance, infrastructure projects like bridges, and temporary setups for events.