Content Menu

● Understanding the Scaffolding Tag System

>> Importance of Scaffolding Tags

● Types of Scaffolding Tags

● Scaffold Tagging Procedures

● Best Practices for Scaffold Tagging

● The Lifesaving Potential of the Scaffolding Tagging System

● Scaffolding Tagging Guidelines

>> Green Tag

>> Red Tag

>> Yellow Tag

● Challenges in Implementing Scaffolding Tag Systems

● Integrating Technology in Scaffolding Safety

● Case Studies Highlighting Successes with Scaffolding Tag Systems

● Conclusion

● FAQ

>> 1. What does a green scaffold tag mean?

>> 2. How often should scaffolds be inspected?

>> 3. Can scaffolding tags be customized?

>> 4. What should workers do if they see a red tag on a scaffold?

>> 5. Are scaffolding tags legally required?

● Citations:

Scaffolding is an essential component in construction, providing temporary structures that allow workers to access high areas safely. However, the safety of these scaffolds is paramount, and this is where the Scaffolding Tag System plays a crucial role. This article will explore the intricacies of the scaffolding tag system, its importance, types, procedures, and best practices for implementation.

Understanding the Scaffolding Tag System

The scaffolding tag system is a visual communication tool designed to convey critical information about the safety and usability of scaffolding structures. It employs a color-coded tagging system that provides immediate information to workers regarding whether a scaffold is safe to use, requires caution, or is unsafe.

Importance of Scaffolding Tags

Scaffolding tags serve several vital functions:

- Safety Communication: They provide clear and immediate information about the scaffold's status.

- Regulatory Compliance: Tags help ensure adherence to safety regulations and standards set by organizations such as OSHA (Occupational Safety and Health Administration).

- Accident Prevention: By clearly marking the condition of scaffolds, tags significantly reduce the risk of accidents on construction sites.

Types of Scaffolding Tags

There are three primary types of scaffold tags, each represented by a distinct color:

- Green Tag: Indicates that the scaffold has been inspected and is safe for use. Workers can proceed without any concerns.

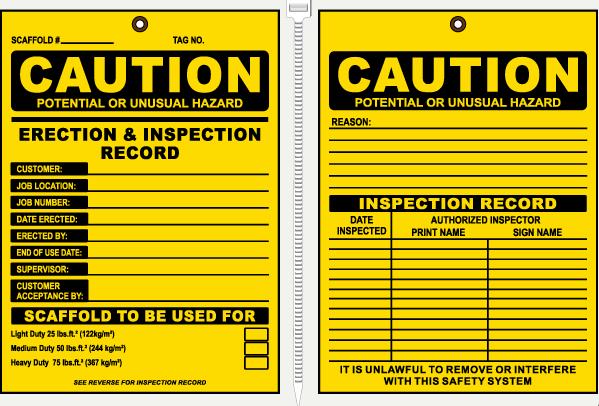

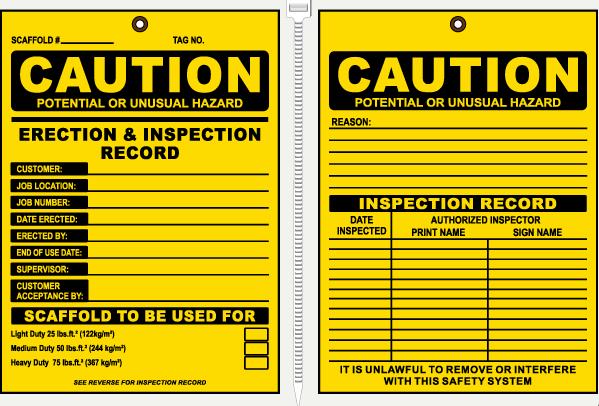

- Yellow Tag: Signifies caution. This tag is used when there are potential hazards associated with the scaffold. It indicates that while the scaffold can be used, workers should be aware of specific risks.

- Red Tag: Represents danger. This tag is attached to scaffolds that are unsafe for use. Workers must avoid these areas until repairs are made and a new inspection is conducted.

Scaffold Tagging Procedures

Implementing an effective scaffolding tagging system involves several key procedures:

1. Inspection: Each scaffold must be inspected by a competent person after assembly and at least weekly thereafter. The inspection should assess structural integrity, load capacity, and compliance with safety standards.

2. Tagging: Based on the inspection results, appropriate tags (green, yellow, or red) should be affixed to the scaffold at each access point. This ensures visibility for all workers.

3. Documentation: Tags should include essential information such as:

- Unique identification number

- Inspection date

- Load capacity

- Inspection results

4. Regular Updates: Tags should be updated regularly or whenever conditions change (e.g., modifications made to the scaffold).

Best Practices for Scaffold Tagging

To maximize the effectiveness of a scaffolding tag system, consider the following best practices:

- Visibility: Ensure tags are placed in prominent locations where they can be easily seen by all workers accessing the scaffold.

- Durability: Use weather-resistant materials for tags to prevent fading or damage from environmental conditions.

- Training: Provide comprehensive training for all workers on how to interpret scaffold tags and understand their significance.

- Regular Audits: Conduct periodic audits of the tagging system to ensure compliance with safety standards and procedures.

The Lifesaving Potential of the Scaffolding Tagging System

At its core, ensuring scaffolding safety lies in understanding that each scaffold is more than just a structure—it's a lifeline for workers who depend on it. The innovative Scaffolding Tagging System employs a straightforward yet profoundly impactful method to relay crucial information regarding the condition and safety status of scaffolding to all potential users. By instituting a mandatory protocol, this system ensures all scaffolding undergoes thorough inspections prior to use.

Scaffolding Tagging Guidelines

The guidelines for scaffolding tagging are straightforward yet comprehensive. They mandate regular inspections by qualified personnel and the use of the tagging system to indicate a scaffold's safety status clearly.

Green Tag

A green tag indicates that a scaffold is safe and ready for use, specifying the class of duty it's approved for.

Red Tag

Red tag warns that the scaffold is unsafe and should not be used under any circumstances.

Yellow Tag

The color yellow means “CAUTION” when it comes to tagging scaffolds. These will replace green tags if a scaffold has been modified for work requirements. It is generally accepted that yellow tags are used when scaffolding is safe for use but modified to suit particular job site requirements.

Challenges in Implementing Scaffolding Tag Systems

While implementing a scaffolding tag system can greatly enhance safety, several challenges may arise:

- Lack of Training: Insufficient training can lead to misinterpretation of tags or improper tagging practices.

- Inconsistent Inspections: If inspections are not conducted regularly or thoroughly, it undermines the effectiveness of the tagging system.

- Environmental Factors: Weather conditions can affect both the physical condition of scaffolds and the visibility of tags, necessitating additional precautions.

Integrating Technology in Scaffolding Safety

As technology advances, integrating digital solutions into scaffolding safety protocols can enhance efficiency and accuracy:

- Mobile Apps: Applications can streamline inspection processes by allowing inspectors to document findings digitally and update tags in real-time.

- Wearable Devices: Smart helmets or vests equipped with sensors can monitor environmental conditions around scaffolds and alert workers to potential hazards.

- Drones: Drones can conduct aerial inspections of hard-to-reach scaffolds, providing detailed assessments without putting workers at risk.

Case Studies Highlighting Successes with Scaffolding Tag Systems

Several construction companies have successfully implemented scaffolding tag systems leading to significant improvements in safety records:

1. Company A reported a 40% reduction in accidents related to scaffold usage after adopting a rigorous tagging protocol combined with comprehensive worker training sessions.

2. Company B, which integrated mobile technology into their inspection process, noted increased efficiency in identifying unsafe structures and addressing issues promptly before accidents could occur.

3. A large infrastructure project utilized drones for regular inspections alongside traditional methods; this dual approach resulted in early detection of potential hazards that would have otherwise gone unnoticed until they posed serious risks.

Conclusion

The scaffolding tag system is an indispensable part of ensuring safety in construction environments. By employing a clear and structured approach to tagging scaffolds, construction companies can significantly enhance worker safety, improve communication regarding scaffold conditions, and ensure compliance with regulatory requirements. The implementation of this system not only protects workers but also fosters a culture of safety awareness on job sites.

FAQ

1. What does a green scaffold tag mean?

A green scaffold tag indicates that the scaffold has been thoroughly inspected and is safe for use.

2. How often should scaffolds be inspected?

Scaffolds should be inspected after assembly and at least weekly thereafter or after any modifications are made.

3. Can scaffolding tags be customized?

Yes, scaffolding tags can be customized to include additional information relevant to specific projects or company requirements.

4. What should workers do if they see a red tag on a scaffold?

Workers must avoid using any scaffold marked with a red tag until it has been repaired and re-inspected.

5. Are scaffolding tags legally required?

While not legally mandated in all jurisdictions, regular inspections are required by law, making tagging an effective method to communicate inspection results.

Citations:

[1] https://coreehs.com/scaffolding-safety-enhancing-accident-prevention-with-tagging-system/

[2] https://coreehs.com/the-critical-role-of-scaffolding-safety-in-2024-lessons-learned-and-best-practices-for-2025/

[3] https://www.oshaoutreachcourses.com/blog/scaffolding-safety-guide/

[4] https://justscaffolders.com/the-ultimate-guide-to-scaffolding-safety-tips-and-best-practices/

[5] https://scaffoldtype.com/scaffold-tagging-system/

[6] https://www.lockoutindia.com/blog/unlocking-safety-the-ultimate-guide-to-scaffolding-tagging-systems/

[7] https://www.eurogulfsafety.in/2023/11/mastering-scaffolding-12-comprehensive.html

[8] https://www.hsestudyguide.com/scaffolding-safety-standards/

[9] https://www.conexpoconagg.com/news/scaffolding-safety-10-essential-tips-and-precautio

[10] https://apacscaffold.com/the-ultimate-guide-of-scaffold-tags/

[11] https://osha4you.com/scaffolding/safety-professionals-play-a-vital-role-in-reducing-scaffolding-hazards-and-preventing-accidents/

[12] https://gocontractor.com/blog/worldwide-scaffolding-safety-regulations/

[13] https://fatfinger.io/scaffolding-safety-when-working-at-height/

[14] https://normlex.ilo.org/dyn/nrmlx_es/f?p=NORMLEXPUB%3A55%3A0%3A%3ANO%3A%3AP55_TYPE%2CP55_LANG%2CP55_DOCUMENT%2CP55_NODE%3AREC%2Cen%2CR053%2C%2FDocument

[15] https://www.dir.ca.gov/dosh/dosh_publications/GuideForSupportedScaffolds.pdf

[16] https://www.assp.org/news-and-articles/guidelines-for-scaffolding-safety