Content Menu

● Introduction to Cuplock Scaffolding

● Key Components of Cuplock Scaffolding

● Best Practices for Cuplock System Scaffolding Design

>> 1. Stability and Safety

>> 2. Efficient Assembly

>> 3. Material Selection

>> 4. Customization

● Applications of Cuplock Scaffolding

● Design Considerations for Cuplock System Scaffolding

● Benefits of Cuplock System Scaffolding Design

● Advanced Features in Cuplock Scaffolding

>> 1. Modular Design

>> 2. Galvanized Finish

>> 3. Customizable Configurations

● Comparison with Other Scaffolding Systems

● Maintenance and Inspection

● Environmental Considerations

● Case Studies

● Conclusion

● FAQ

>> 1. What are the core components of a cuplock scaffolding system?

>> 2. What are the benefits of using cuplock scaffolding in construction?

>> 3. How does cuplock scaffolding ensure stability?

>> 4. What are the common applications of cuplock scaffolding?

>> 5. What certifications should cuplock scaffolding systems meet?

● Citations:

The cuplock system scaffolding design is renowned for its efficiency, versatility, and reliability in construction projects. It is crucial to optimize this design to ensure safety, stability, and cost-effectiveness. In this article, we will delve into the key components and best practices for designing cuplock scaffolding systems.

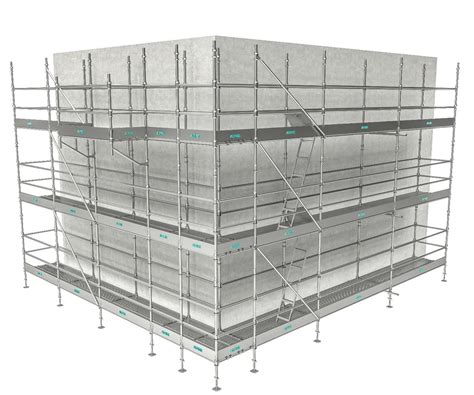

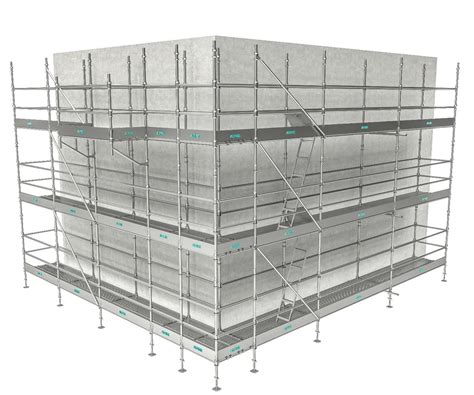

Introduction to Cuplock Scaffolding

Cuplock scaffolding is a modular system that uses a unique node locking mechanism, allowing for quick assembly without loose parts. This system consists of vertical standards, horizontal ledgers, diagonal braces (transoms), and planks, all working together to create a robust structure.

Key Components of Cuplock Scaffolding

- Vertical Standards (Standards): These are the vertical pillars of the scaffolding system, equipped with cup-shaped connectors at regular intervals.

- Horizontal Ledgers (Ledgers): These connect to the vertical standards, creating a stable framework.

- Diagonal Braces (Transoms): These provide stability by connecting ledgers at an angle.

- Planks: These serve as working platforms for construction workers.

Best Practices for Cuplock System Scaffolding Design

1. Stability and Safety

Ensure that the scaffolding is levelled and securely anchored to prevent sway and collapse. Use diagonal braces to enhance stability.

2. Efficient Assembly

Utilize the cuplock node locking mechanism to quickly assemble and disassemble the scaffolding. This reduces labor costs and project timelines.

3. Material Selection

Choose high-grade materials that meet international standards such as EN 12811-1 to ensure durability and safety.

4. Customization

Design the scaffolding to fit specific project needs, including varying heights and configurations.

Applications of Cuplock Scaffolding

Cuplock scaffolding is versatile and can be used in various settings:

- Construction Projects: Ideal for building, repairing, and maintaining structures.

- Industrial Maintenance: Used in workshops and factories.

- Event Staging: Suitable for temporary stands and stages.

- Ship Repair: Often used in shipyards.

Design Considerations for Cuplock System Scaffolding

When designing a cuplock scaffolding system, consider the following:

1. Load Capacity: Ensure that the scaffolding can support the weight of workers, materials, and equipment.

2. Wind Resistance: Use diagonal braces and secure anchoring to resist wind forces.

3. Accessibility: Incorporate walkways and staircases for safe access.

Benefits of Cuplock System Scaffolding Design

Cuplock scaffolding offers several advantages:

- Speed and Efficiency: Quick assembly and disassembly reduce labor costs.

- Safety and Stability: The secure locking mechanism enhances stability and safety.

- Cost-effectiveness: Reusable components offer long-term cost savings.

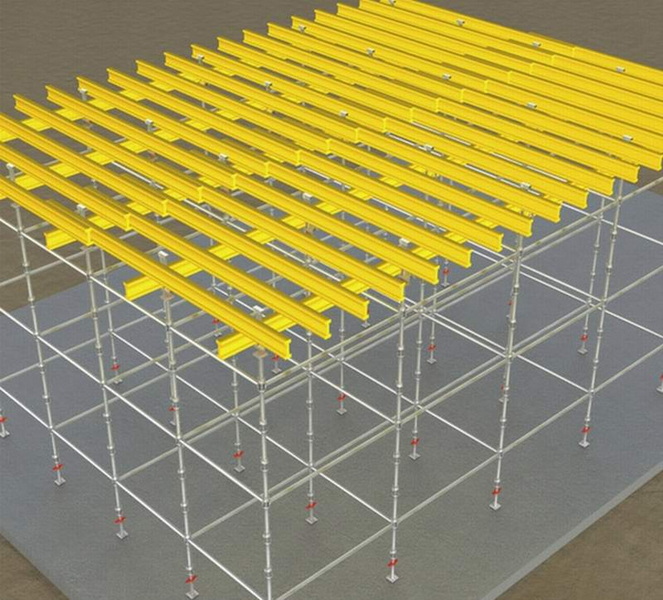

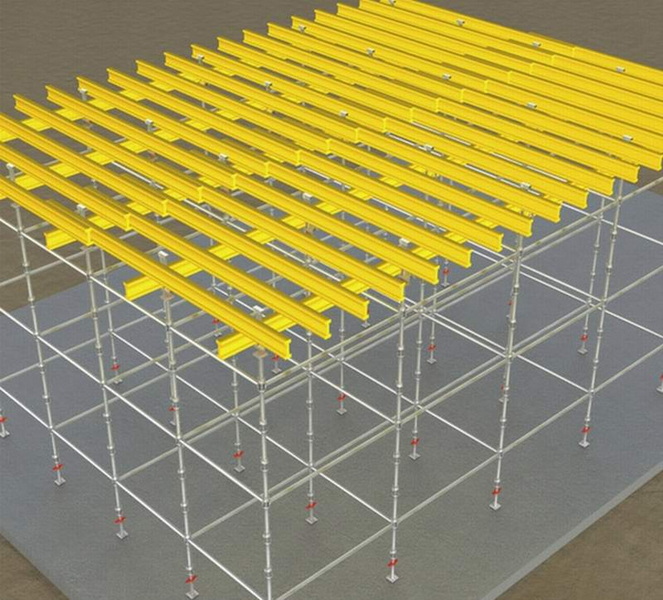

Advanced Features in Cuplock Scaffolding

1. Modular Design

The modular nature allows for easy expansion or reduction of the scaffolding structure as needed.

2. Galvanized Finish

A galvanized finish provides corrosion resistance, extending the lifespan of the scaffolding components.

3. Customizable Configurations

Cuplock scaffolding can be configured to fit complex building shapes or irregular surfaces.

Comparison with Other Scaffolding Systems

Cuplock scaffolding is often compared to other systems like Kwikstage and Ringlock:

- Kwikstage Scaffolding: Known for its simplicity and cost-effectiveness but may not offer the same level of stability as cuplock.

- Ringlock Scaffolding: Offers high load capacity and flexibility but can be more complex to assemble.

Maintenance and Inspection

Regular maintenance and inspection are crucial to ensure the longevity and safety of cuplock scaffolding systems:

- Regular Cleaning: Remove dirt and debris to prevent corrosion.

- Inspection: Check for damage or wear on components before use.

Environmental Considerations

Cuplock scaffolding systems can be designed with environmental considerations in mind:

- Sustainable Materials: Use materials that are recyclable or sustainably sourced.

- Minimizing Waste: Ensure that scaffolding components are reusable to reduce waste.

Case Studies

Several construction projects have successfully utilized cuplock scaffolding systems:

- High-Rise Buildings: Cuplock scaffolding has been used in the construction of high-rise buildings due to its stability and flexibility.

- Bridge Repair: It is also used in bridge repair projects for its ability to withstand harsh weather conditions.

Conclusion

The cuplock system scaffolding design is a crucial element in ensuring the success and safety of construction projects. By optimizing this design with considerations for stability, efficiency, and customization, contractors can enhance productivity while maintaining high safety standards.

FAQ

1. What are the core components of a cuplock scaffolding system?

The core components include vertical standards, horizontal ledgers, diagonal braces (transoms), and planks, all connected using a unique node locking mechanism.

2. What are the benefits of using cuplock scaffolding in construction?

Cuplock scaffolding offers speed and efficiency in assembly, enhanced safety and stability, and cost-effectiveness due to reusable components.

3. How does cuplock scaffolding ensure stability?

Stability is ensured through the use of diagonal braces (transoms) and secure anchoring to prevent sway and collapse.

4. What are the common applications of cuplock scaffolding?

Cuplock scaffolding is commonly used in construction projects, industrial maintenance, event staging, and ship repair.

5. What certifications should cuplock scaffolding systems meet?

Cuplock scaffolding systems should meet international standards such as EN 12811-1 to ensure safety and durability.

Citations:

[1] https://www.linkedin.com/pulse/cuplock-system-scaffolding-versatile-quality-assured-scaffold-mishra

[2] https://www.youtube.com/watch?v=fnJw0xLZE5s

[3] https://www.paramount-scaffold.com/cuplock-system

[4] https://www.youtube.com/watch?v=3rbyXSf_MYE

[5] https://aaitscaffold.com/cuplock-scaffolding/everything-about-cuplock-scaffolding-system/

[6] https://www.youtube.com/watch?v=-ScFRrK-FKo

[7] https://www.huennebeck.com/uploads/files/cuplok_system_scaffold_user_guide_en_2015-05-29.pdf

[8] https://www.youtube.com/watch?v=2FbwLFj1aFY

[9] https://www.youtube.com/watch?v=ojYR6MRAoEI