Content Menu

● Introduction to Scaffolding Couplers

● Types of Scaffolding Couplers

● Fixed Scaffolding Couplers

● Characteristics of Fixed Couplers

● Swivel Scaffolding Couplers

● Characteristics of Swivel Couplers

● Comparison of Fixed and Swivel Couplers

● Applications of Fixed and Swivel Couplers

● Safety Considerations

● Innovations in Scaffolding Couplers

● Conclusion

● FAQ

>> 1. What is the primary difference between fixed and swivel scaffolding couplers?

>> 2. What are the main applications of fixed scaffolding couplers?

>> 3. What are the advantages of using swivel scaffolding couplers?

>> 4. How do you ensure the safety of scaffolding structures using couplers?

>> 5. What materials are scaffolding couplers typically made of?

● Citations:

Scaffolding couplers are essential components in construction, providing a secure connection between scaffolding tubes to ensure structural integrity and safety. Among the various types of scaffolding couplers, fixed and swivel couplers are two of the most commonly used. In this article, we will explore the differences between these two types, their applications, and how they contribute to the stability and flexibility of scaffolding structures.

Introduction to Scaffolding Couplers

Scaffolding couplers are devices used to connect scaffolding tubes, ensuring that the structure remains stable and secure. There are several types of couplers, each designed for specific purposes and applications.

Types of Scaffolding Couplers

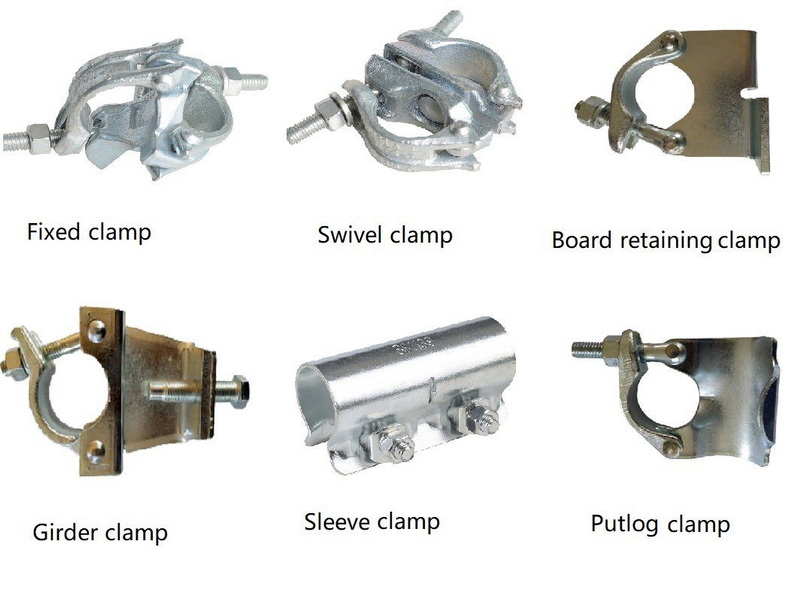

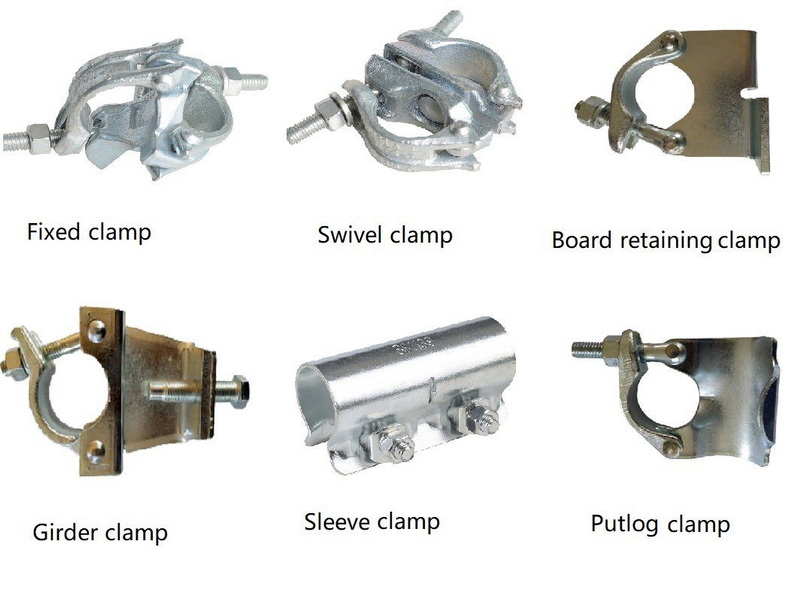

The primary types of scaffolding couplers include:

1. Right-Angle Couplers: These couplers connect two scaffolding tubes at a 90-degree angle, creating strong and sturdy joints. They are essential for standard vertical and horizontal joints in scaffolding systems[1][2].

2. Swivel Couplers: Swivel couplers allow tubes to be connected at any angle, providing flexibility in complex scaffolding configurations. They are ideal for diagonal bracing or irregular structures[1][2].

3. Sleeve Couplers: Sleeve couplers connect two scaffolding tubes end-to-end, extending the length of vertical or horizontal members while maintaining structural integrity[1][4].

4. Putlog Couplers: These couplers attach horizontal putlogs (transoms) to vertical standards, often used for platforms and walkways[1][5].

5. Beam Couplers: Beam couplers clamp scaffolding tubes to steel beams or other structural elements, crucial for anchoring scaffolding to buildings or bridges[1][5].

Fixed Scaffolding Couplers

Fixed scaffolding couplers, such as right-angle couplers, are designed to connect tubes at a fixed angle, typically 90 degrees. They are widely used in construction sites for creating stable scaffolding structures.

Characteristics of Fixed Couplers

- Stability: Fixed couplers provide excellent stability, ensuring that the scaffolding structure remains firm and secure.

- Load Capacity: They have a high load capacity, making them suitable for heavy-duty applications.

- Ease of Use: Fixed couplers are straightforward to install and require minimal maintenance.

Swivel Scaffolding Couplers

Swivel scaffolding couplers are versatile connectors that allow tubes to be connected at any angle. They are particularly useful in complex scaffolding setups where flexibility is required.

Characteristics of Swivel Couplers

- Flexibility: Swivel couplers offer the ability to adjust the angle between tubes, making them ideal for irregular or curved scaffolding configurations.

- Adaptability: They can be used in a variety of situations, including diagonal bracing and unique structural designs.

- Ease of Adjustment: Swivel couplers allow for easy adjustments without the need for additional tools or components.

Comparison of Fixed and Swivel Couplers

| Feature | Fixed Couplers | Swivel Couplers |

| Angle Flexibility | Fixed at 90 degrees | Adjustable at any angle |

| Stability | High stability | Good stability, but may require additional support |

| Load Capacity | High load capacity | Lower load capacity compared to fixed couplers |

| Ease of Use | Easy to install | Easy to adjust, but may require more maintenance |

Applications of Fixed and Swivel Couplers

Both fixed and swivel couplers have diverse applications across various industries:

- Construction Sites: Fixed couplers are commonly used for standard scaffolding setups, while swivel couplers are used for complex or irregular structures.

- Building Maintenance: Swivel couplers are beneficial for accessing hard-to-reach areas with unique angles, while fixed couplers provide stability for routine maintenance tasks.

- Event and Entertainment Industry: Swivel couplers are often used in setting up stages and lighting rigs with complex configurations.

Safety Considerations

Safety is paramount when using scaffolding couplers. Here are some key considerations:

- Training: Ensure that all personnel using scaffolding are properly trained on the safe assembly and disassembly of scaffolding structures.

- Safety Equipment: Always use appropriate safety equipment, such as harnesses and hard hats, when working on scaffolding.

- Regular Inspections: Conduct regular inspections of the scaffolding structure to identify any potential hazards or defects.

Innovations in Scaffolding Couplers

Recent innovations in scaffolding couplers include:

1. Material Advancements: New materials like advanced alloys and composites are being used to make couplers lighter, stronger, and more resistant to corrosion.

2. Smart Couplers: Some companies are developing smart couplers with integrated sensors that monitor load capacity and structural integrity in real-time, enhancing safety and efficiency.

3. Sustainable Practices: There is a growing focus on sustainable practices in scaffolding, including the use of recycled materials and energy-efficient manufacturing processes for couplers.

Conclusion

Fixed and swivel scaffolding couplers each have unique advantages and applications. Understanding their differences is crucial for selecting the right coupler for specific scaffolding needs, ensuring both safety and efficiency in construction projects. By choosing the appropriate type of coupler, construction teams can enhance the stability and flexibility of their scaffolding structures.

FAQ

1. What is the primary difference between fixed and swivel scaffolding couplers?

The primary difference is that fixed couplers connect tubes at a fixed angle (typically 90 degrees), while swivel couplers allow for adjustable connections at any angle.

2. What are the main applications of fixed scaffolding couplers?

Fixed couplers are commonly used in standard scaffolding setups where stability is crucial, such as in construction sites and building maintenance.

3. What are the advantages of using swivel scaffolding couplers?

Swivel couplers offer flexibility and adaptability, making them ideal for complex or irregular scaffolding configurations.

4. How do you ensure the safety of scaffolding structures using couplers?

Safety is ensured by proper training, using safety equipment, and conducting regular inspections of the scaffolding structure.

5. What materials are scaffolding couplers typically made of?

Scaffolding couplers are typically made from high-strength materials such as steel or aluminum, which provide durability and resistance to corrosion.

Citations:

[1] https://www.adtoscaffold.com/new/how_many_kinds_of_scaffolding_coupler_are_there.html

[2] https://apacsafety.com/the-ultimate-guide-of-scaffolding-couplers/

[3] https://www.wm-scaffold.com/scaffolding-coupler.html

[4] https://www.linkedin.com/pulse/comprehensive-guide-types-couplers-scaffolding-abhishek-mishra

[5] https://grsscaffolding.com/blog/scaffolding-couplers-types/

[6] https://www.gd-scaffold.com/news/types-of-couplers-in-scaffolding.html

[7] https://murariengineeringworks.com/what-are-scaffolding-couplers-types-characteristics-and-precautions/

[8] https://wslindia.com/types-of-scaffolding-couplers/