Content Menu

● Introduction to Cuplock Scaffolding

● Components of Cuplock Scaffolding

● Factors Influencing the Load Capacity of Cuplock Scaffolding

● Typical Load Capacities of Cuplock Scaffolding

>> Vertical Load Capacity

>> Horizontal Load Capacity

● Ensuring Safety and Compliance

● Advanced Applications of Cuplock Scaffolding

● Innovations in Cuplock Scaffolding

● Case Studies: Successful Use of Cuplock Scaffolding

● Conclusion

● FAQ

>> 1. What is the typical load capacity of light-duty cuplock scaffolding?

>> 2. How does the design of cuplock scaffolding affect its load capacity?

>> 3. What materials are commonly used in cuplock scaffolding?

>> 4. How often should cuplock scaffolding be inspected?

>> 5. What are the benefits of using cuplock scaffolding in construction projects?

● Citations:

Cuplock scaffolding is a widely used system in the construction industry, renowned for its robustness, versatility, and ease of assembly. One of the critical aspects that make it indispensable for construction projects is its impressive load capacity. Understanding the load capacity of cuplock scaffolding is essential for ensuring safety and efficiency on any worksite. In this article, we will delve into the factors that determine the load capacity of cuplock scaffolding, explore its typical load capacities, and discuss how to ensure safe and efficient use.

Introduction to Cuplock Scaffolding

Cuplock scaffolding is a modular system made of vertical standards and horizontal ledgers, connected by a unique "cup and blade" locking mechanism. This design allows for quick assembly and disassembly, saving time and labor costs. The system is ideal for various applications, including building facades, bridges, and industrial maintenance.

Components of Cuplock Scaffolding

1. Vertical Standards: These are the main uprights of the scaffolding system, typically made from high-strength steel with a diameter of 48.3mm and a thickness of 3.2mm.

2. Horizontal Ledgers: These connect the vertical standards, providing a framework for the scaffolding platform. They also use a diameter of 48.3mm and a thickness of 3.2mm.

3. Cuplock Node: This is the innovative locking mechanism that allows for easy connection and disconnection of the scaffolding components.

4. Diagonal Braces: These provide additional stability to the scaffolding structure, ensuring it can withstand various external forces.

Factors Influencing the Load Capacity of Cuplock Scaffolding

Several factors determine the load capacity of cuplock scaffolding:

1. Material Quality: Cuplock scaffolding is typically made from high-strength steel, such as S355 or S235, which directly impacts its load-bearing capacity.

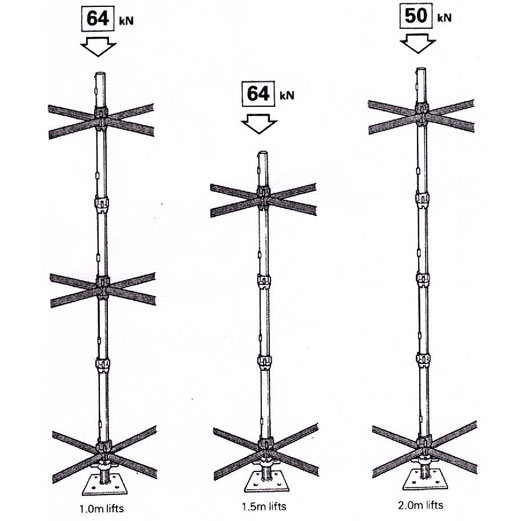

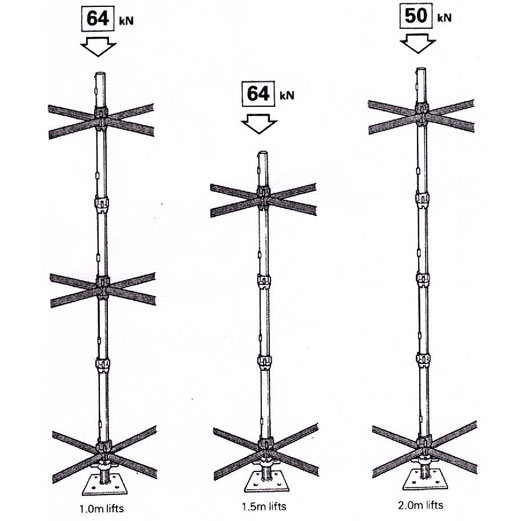

2. Design and Configuration: The arrangement of standards and ledgers significantly affects the distribution of load. Closer spacing between standards can support heavier loads.

3. Foundation Stability: A stable and well-prepared base prevents excessive stress and potential failure.

4. Usage Conditions: External factors such as wind load, vibrations, or additional weight from construction materials and equipment can influence performance.

5. Maintenance and Inspection: Regular maintenance and inspections are crucial to ensure that the scaffolding remains in good condition and can support its intended load.

Typical Load Capacities of Cuplock Scaffolding

The load capacity of cuplock scaffolding varies depending on the specific product and configuration. However, as a general guideline:

- Light-Duty (Low Load): Suitable for tasks involving a few workers and hand tools, light-duty scaffolding can typically support around 75 kg per square meter.

- Medium-Duty (Standard Load): Used for more intensive work with multiple workers, materials, and heavier tools, medium-duty scaffolding can support approximately 150 kg per square meter.

- Heavy-Duty (High Load): Designed for projects requiring significant material storage or heavy equipment, heavy-duty scaffolding can bear loads of 275 kg per square meter or more.

Vertical Load Capacity

A single standard in a properly erected cuplock system can typically support up to 2 to 3 tons of vertical load.

Horizontal Load Capacity

Horizontally, the load is distributed among ledgers and transoms, with a typical load-bearing capacity of around 1 ton per ledger, depending on the spacing.

Ensuring Safety and Compliance

To maintain safety and structural integrity, it's essential to:

1. Consult Manufacturer Specifications: Always refer to the manufacturer's guidelines for specific load capacities and adhere to recommended limits.

2. Conduct Regular Inspections: Ensure that the scaffolding is inspected by a competent person before use and regularly thereafter, especially after any alterations or exposure to adverse weather conditions.

3. Distribute Weight Evenly: Load distribution is key to preventing overloading. Ensure that materials are evenly spread out across the platform and that heavy loads are placed directly over the standards.

4. Train Workers: All personnel should be aware of the load limits and trained in the proper use and handling of materials on the scaffolding.

5. Use Safety Equipment: Ensure that workers use appropriate safety gear, such as harnesses and safety nets, to prevent accidents.

Advanced Applications of Cuplock Scaffolding

Cuplock scaffolding is versatile and can be adapted for complex projects:

1. Bridge Maintenance: Its modular design allows for easy setup on bridges, facilitating maintenance and repair work.

2. High-Rise Construction: Cuplock scaffolding can be extended to great heights, making it suitable for high-rise building projects.

3. Industrial Maintenance: It is often used in industrial settings for maintenance tasks that require access to high areas.

Innovations in Cuplock Scaffolding

Recent innovations have further enhanced the efficiency and safety of cuplock scaffolding systems:

1. Improved Materials: New materials and coatings offer better durability and resistance to corrosion.

2. Enhanced Locking Mechanisms: Upgraded locking systems provide easier assembly and disassembly, reducing labor time.

3. Integration with Technology: Some modern systems incorporate digital tools for monitoring load capacities and structural integrity in real-time.

Case Studies: Successful Use of Cuplock Scaffolding

Several notable construction projects have successfully utilized cuplock scaffolding:

1. High-Rise Building Projects: Cuplock scaffolding has been used in numerous high-rise projects worldwide, providing reliable access for construction and maintenance.

2. Bridge Renovation: In a recent bridge renovation project, cuplock scaffolding allowed workers to safely access and repair critical structural elements.

3. Industrial Plant Maintenance: Cuplock scaffolding has been instrumental in facilitating maintenance tasks at industrial plants, ensuring minimal downtime.

Conclusion

In conclusion, the load capacity of cuplock scaffolding is a critical factor in ensuring the safety and efficiency of construction projects. By understanding the factors that influence load capacity and adhering to manufacturer specifications, project managers and workers can ensure the structural integrity and reliability of their scaffolding setup. The versatility and adaptability of cuplock scaffolding make it an indispensable tool in the construction industry.

FAQ

1. What is the typical load capacity of light-duty cuplock scaffolding?

Light-duty cuplock scaffolding typically supports around 75 kg per square meter, suitable for tasks involving a few workers and hand tools.

2. How does the design of cuplock scaffolding affect its load capacity?

The design and configuration of cuplock scaffolding, including the spacing of standards and ledgers, significantly impact its load-bearing capacity. Closer spacing can support heavier loads.

3. What materials are commonly used in cuplock scaffolding?

Cuplock scaffolding is typically made from high-strength steel, such as S355 or S235, with a hot-dip galvanized finish for durability.

4. How often should cuplock scaffolding be inspected?

Cuplock scaffolding should be inspected by a competent person before use and regularly thereafter, especially after any alterations or exposure to adverse weather conditions.

5. What are the benefits of using cuplock scaffolding in construction projects?

Cuplock scaffolding offers benefits such as faster erection, cost efficiency, and versatility in applications, making it ideal for a wide range of construction needs.

Citations:

[1] https://primesteeltech.co.in/what-is-the-load-capacity-of-a-cuplock-scaffold.html

[2] https://www.youtube.com/watch?v=wBKilb9ALEY

[3] https://rapid-scafform.com/cuplock-scaffold/

[4] https://shelterrc.com/what-is-the-load-capacity-of-a-cuplock-scaffold/

[5] https://www.wm-scaffold.com/cup-lock-scaffold.html

[6] https://www.youtube.com/watch?v=fnJw0xLZE5s

[7] https://aaitscaffold.com/blog/cuplock-scaffolding-types-uses-benefits-and-safety/

[8] https://www.linkedin.com/posts/sohail-abbas-26181a241_how-to-calculate-load-capacity-of-scaffolding-activity-7155125860549689344-FYOB

[9] https://jumplyscaffolding.com/what-is-cuplock-scaffolding/