Content Menu

● Introduction to Ladder Clamps for Scaffolding

● Why Are Ladder Clamps Essential?

>> Preventing Accidents and Ensuring Worker Safety

>> Compliance With Safety Regulations

● How Does a Ladder Clamp for Scaffolding Work?

● Types of Ladder Clamps for Scaffolding

● Key Benefits of Using Ladder Clamps

● How to Install a Ladder Clamp for Scaffolding

● Safety Standards and Compliance

● Best Practices and Common Mistakes

>> Best Practices

>> Common Mistakes to Avoid

● Common Safety Hazards and How Ladder Clamps Mitigate Them

● Tips for Choosing the Right Ladder Clamp

● Common Applications and Industries Using Ladder Clamps

● Maintenance and Care of Ladder Clamps

● Innovations and Future Trends in Ladder Clamps

● Training and Education for Safe Ladder Clamp Use

● Conclusion

● FAQ

>> 1. What is the primary purpose of using a ladder clamp for scaffolding?

>> 2. What types of ladders are compatible with ladder clamps for scaffolding?

>> 3. How often should ladder clamps for scaffolding be inspected?

>> 4. Are there specific safety regulations regarding the use of ladder clamps for scaffolding?

>> 5. Can I use any type of clamp to secure a ladder to scaffolding?

Working at height is a daily reality in construction, maintenance, and industrial environments. Scaffolding provides stable platforms for such work, but safe and efficient access to these platforms is only possible with secure ladders. Enter the ladder clamp for scaffolding: a small but critical component that ensures ladders remain firmly attached to scaffold structures, dramatically reducing the risk of slips, falls, and accidents.

Introduction to Ladder Clamps for Scaffolding

A ladder clamp for scaffolding is a mechanical device designed to securely fasten a ladder to a scaffold tube or frame. Its primary purpose is to prevent the ladder from slipping, shifting, or tipping over during use, thereby providing a stable and safe means of access for workers at height. These clamps are vital in construction, building maintenance, industrial settings, and any scenario where ladders are used to access elevated platforms.

Why Are Ladder Clamps Essential?

Preventing Accidents and Ensuring Worker Safety

Falls from height are among the leading causes of workplace injuries and fatalities. Many such incidents occur due to unsecured or unstable ladders. A ladder clamp for scaffolding directly addresses this hazard by anchoring the ladder to the scaffold, minimizing the risk of accidental movement and providing a secure climbing route for workers.

Compliance With Safety Regulations

Many industry safety standards and regulations, such as OSHA guidelines and BSI standards (e.g., BS1139), require ladders to be properly secured to scaffolding structures. Using a ladder clamp for scaffolding helps organizations comply with these regulations, avoiding legal penalties and ensuring a safer work environment.

How Does a Ladder Clamp for Scaffolding Work?

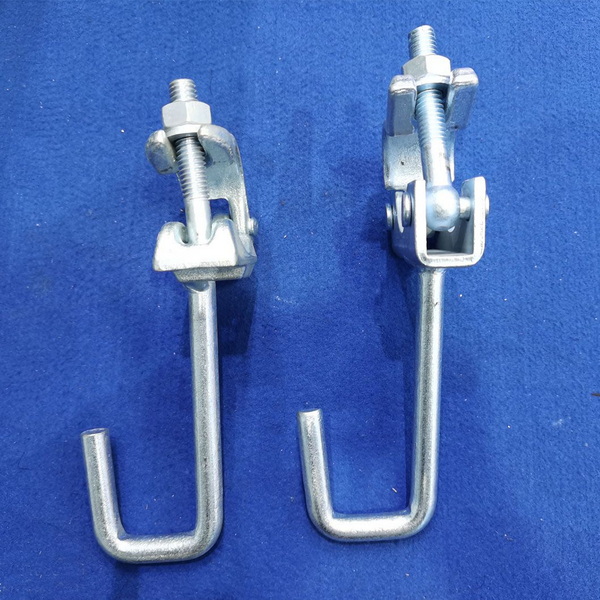

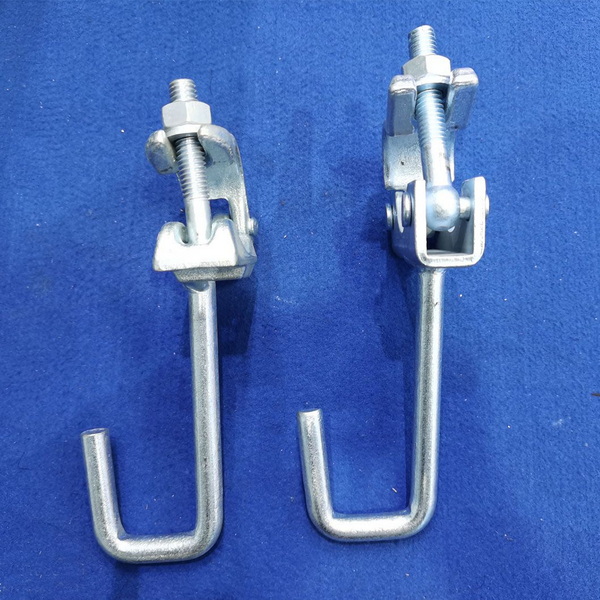

A ladder clamp for scaffolding typically consists of a robust metal clamp with a locking mechanism. The clamp is designed to grip both the ladder stile (side rail) and the scaffold tube, holding them tightly together. Installation is straightforward and usually requires no special tools-most clamps can be tightened by hand or with a simple wrench.

Step-by-step operation:

1. Position the ladder against the scaffold at the desired access point.

2. Align the clamp so it grips both the ladder stile and the scaffold tube.

3. Tighten the clamp until the ladder is firmly secured and cannot move independently.

4. Repeat on the opposite stile for maximum stability (ladder clamps should always be used in pairs).

Types of Ladder Clamps for Scaffolding

| Type | Description | Typical Use Case |

| Fixed Ladder Clamp | Designed for specific ladder and scaffold tube sizes; offers a permanent fit | Standard scaffold setups |

| Adjustable Ladder Clamp | Can be modified to fit various ladder widths and tube diameters | Versatile, multi-size applications |

| Locking Ladder Clamp | Features a lock to prevent accidental disengagement | High-security or high-traffic areas |

| Universal Ladder Clamp | Fits a wide range of ladders and scaffolds | General construction and maintenance |

| Pressed Steel Clamp | Lightweight, cost-effective, for less demanding tasks | Light-duty or short-term projects |

| Forged Steel Clamp | Heavy-duty, high load capacity | Industrial and large-scale projects |

Key Benefits of Using Ladder Clamps

- Enhanced Safety: Prevents ladder slips, shifts, and falls by securing the ladder in place.

- Improved Stability: Integrates the ladder into the scaffold structure, increasing overall rigidity.

- Efficiency: Allows workers to move quickly and confidently between scaffold levels without constant adjustment.

- Equipment Protection: Reduces wear and tear on both ladders and scaffolding by preventing friction and impact damage.

- Versatility: Adjustable and universal clamps accommodate various ladder and scaffold types.

- Compliance: Meets or exceeds safety regulations, ensuring legal and operational safety.

How to Install a Ladder Clamp for Scaffolding

Step-by-Step Guide:

1. Inspect the Ladder and Scaffold: Ensure both are in good condition and free from damage.

2. Position the Ladder: Place the ladder at a safe angle (typically 75–80 degrees) with its base on a stable surface.

3. Attach the Clamp: Place the clamp over the ladder stile and the scaffold tube at the desired height.

4. Tighten the Clamp: Secure the clamp by hand or with a wrench, ensuring it is tight but not over-tightened.

5. Double Check: Ensure the ladder is firmly attached and does not move independently.

6. Repeat for the Other Side: Always use at least two clamps (one on each stile) for maximum security.

Safety Standards and Compliance

Ladder clamps for scaffolding are manufactured to comply with international safety standards, such as:

- BS1139: British Standard for scaffolding fittings and ladder clamps.

- EN 74: European Standard for scaffolding couplers.

- OSHA Guidelines: U.S. Occupational Safety and Health Administration requirements for ladder safety.

Using compliant clamps ensures your site meets legal safety obligations and reduces liability.

Best Practices and Common Mistakes

Best Practices

- Inspect clamps before each use for damage, wear, or corrosion.

- Follow manufacturer's instructions for installation and tightening.

- Use the correct clamp type for your ladder and scaffold configuration.

- Train workers on proper clamp usage and ladder safety.

- Regularly re-inspect clamps during long projects.

Common Mistakes to Avoid

- Using damaged or worn clamps

- Over-tightening, which can damage equipment

- Exceeding load capacity

- Improper installation or using the wrong type of clamp

- Neglecting regular inspections

Common Safety Hazards and How Ladder Clamps Mitigate Them

Working at height involves several safety hazards, many of which can be mitigated by the proper use of ladder clamps for scaffolding. Common hazards include ladder slippage, tipping, and structural instability.

Ladder slippage often occurs when the base or top of the ladder is not securely anchored, leading to sudden shifts that can cause falls. Ladder clamps prevent this by firmly attaching the ladder to the scaffold, eliminating movement.

Tipping hazards arise when ladders are not properly aligned or when workers overreach. Ladder clamps stabilize the ladder, reducing the risk of tipping and providing a secure climbing path.

Structural instability can result from using incompatible or damaged clamps, which may fail under load. Using high-quality, compliant ladder clamps ensures the scaffold and ladder work as a unified, stable system.

By understanding these hazards and using ladder clamps correctly, workplaces can significantly reduce accidents and improve overall safety.

Tips for Choosing the Right Ladder Clamp

Selecting the appropriate ladder clamp for your scaffolding needs is crucial for ensuring safety and efficiency. Here are some tips to help you make the right choice:

1. Consider the Ladder and Scaffold Size: Ensure the clamp fits the dimensions of your ladder stiles and scaffold tubes. Adjustable clamps offer flexibility for different sizes.

2. Check Load Capacity: Choose clamps that can support the weight of the ladder and the maximum expected load, including workers and equipment.

3. Material Quality: Opt for clamps made from durable materials such as forged steel or high-grade aluminum to withstand harsh conditions.

4. Ease of Installation: Look for clamps that are easy to install and remove, especially if frequent repositioning is required.

5. Compliance with Safety Standards: Verify that the clamps meet relevant safety regulations and standards for your region.

6. Additional Features: Some clamps come with locking mechanisms or anti-slip coatings for enhanced security.

By considering these factors, you can select ladder clamps that provide optimal safety and performance for your specific scaffolding setup.

Common Applications and Industries Using Ladder Clamps

Ladder clamps for scaffolding are widely used across various industries where working at height is common. Construction sites are the primary users, where scaffolding and ladders are essential for building, renovation, and maintenance tasks. Industrial facilities also rely on ladder clamps to ensure safe access to elevated machinery and storage areas.

Other industries benefiting from ladder clamps include shipbuilding, where secure ladder access is critical for safety during vessel construction and repair. Event management and stage setup teams use scaffolding and ladders extensively, making ladder clamps vital for worker safety. Additionally, utility companies employ ladder clamps when working on power lines, telecommunications towers, and other infrastructure requiring elevated access.

The versatility and safety provided by ladder clamps make them indispensable in any industry involving elevated work platforms.

Maintenance and Care of Ladder Clamps

Proper maintenance and care of ladder clamps for scaffolding are essential to ensure their longevity and reliable performance. Regular cleaning to remove dirt, debris, and rust can prevent clamp malfunction. Lubricating moving parts with appropriate oils helps maintain smooth operation and prevents corrosion. It is also important to store clamps in a dry, sheltered environment when not in use to avoid exposure to harsh weather conditions that can degrade materials.

Routine inspections should include checking for cracks, bends, or any signs of metal fatigue. Damaged clamps must be replaced immediately to maintain safety standards. Additionally, training workers on proper handling and storage practices can extend the life of ladder clamps and reduce the risk of accidents caused by equipment failure.

Innovations and Future Trends in Ladder Clamps

As safety standards evolve and technology advances, ladder clamps for scaffolding are also seeing innovations aimed at improving safety, ease of use, and durability. New materials such as lightweight alloys and composite materials are being developed to reduce the weight of clamps without compromising strength.

Smart ladder clamps equipped with sensors are emerging, capable of detecting improper installation or excessive movement, alerting workers in real-time to potential hazards. These innovations aim to reduce accidents and enhance worker confidence.

Additionally, ergonomic designs are being introduced to simplify installation and removal, reducing worker fatigue and increasing efficiency on job sites. Future trends also include integration with digital safety management systems, allowing for better tracking and maintenance scheduling of ladder clamps.

These advancements promise to make ladder clamps even more effective and user-friendly in the years to come.

Training and Education for Safe Ladder Clamp Use

Proper training and education are critical components of ladder clamp safety. Workers should be trained on the correct installation, inspection, and use of ladder clamps to prevent accidents. Training programs should include hands-on demonstrations, safety protocols, and emergency procedures.

Employers should ensure that all personnel understand the importance of using ladder clamps and the risks associated with improper use. Regular refresher courses and safety meetings can reinforce best practices and keep safety top of mind.

Incorporating ladder clamp safety into broader workplace safety programs helps create a culture of safety and responsibility. Well-informed workers are more likely to use equipment correctly and report any issues promptly, reducing the likelihood of accidents.

Conclusion

The ladder clamp for scaffolding is a fundamental safety device that transforms a simple ladder into a secure, stable access point for elevated work. By preventing slips, shifts, and falls, ladder clamps protect workers, enhance productivity, and ensure compliance with safety regulations. Their versatility, ease of use, and cost-effectiveness make them indispensable for any project involving scaffolding. For maximum benefit, always use high-quality, compliant clamps, follow best practices for installation and inspection, and provide proper training to all personnel.

FAQ

1. What is the primary purpose of using a ladder clamp for scaffolding?

The main purpose is to securely attach a ladder to a scaffold structure, preventing the ladder from slipping, shifting, or tipping over, thereby reducing the risk of falls and injuries.

2. What types of ladders are compatible with ladder clamps for scaffolding?

Ladder clamps are compatible with a variety of ladders, including aluminum, fiberglass, and wooden ladders. Adjustable and universal clamps offer the most flexibility for different ladder sizes and types.

3. How often should ladder clamps for scaffolding be inspected?

Ladder clamps should be inspected before each use and regularly during long projects. Look for signs of wear, damage, or corrosion, and replace any faulty clamps immediately.

4. Are there specific safety regulations regarding the use of ladder clamps for scaffolding?

Yes, many safety standards (such as BS1139, EN 74, and OSHA guidelines) require ladders to be securely attached to scaffolding using appropriate clamps. Using compliant clamps helps ensure legal and operational safety.

5. Can I use any type of clamp to secure a ladder to scaffolding?

No, only clamps specifically designed for securing ladders to scaffolding should be used. Other types of clamps may not provide the necessary stability or safety and could result in accidents.