Content Menu

● Overview of Aluminum Scaffold Planks

● Specifications of the 7 Aluminum Scaffold Plank

● Weight Capacity

● Applications of the 7 Aluminum Scaffold Plank

>> Construction and Maintenance

>> Scaffolding Systems

>> Specialized Use Cases

● Safety Guidelines

>> Inspection and Maintenance

>> Erection and Dismantling

>> Load Capacity

>> Fall Protection

● Advantages Over Traditional Materials

>> Durability

>> Portability

>> Environmental Resistance

● Common Misconceptions

● Conclusion

● FAQ

>> 1. What are the dimensions of a standard 7 aluminum scaffold plank?

>> 2. What is the weight capacity of a 7 aluminum scaffold plank?

>> 3. Are aluminum scaffold planks better than wooden planks?

>> 4. How should aluminum scaffold planks be inspected before use?

>> 5. Can aluminum scaffold planks be used with different types of scaffolding systems?

● Citations:

Aluminum scaffold planks are widely used in construction and maintenance projects due to their durability, lightweight nature, and resistance to corrosion. Among these planks, the 7 aluminum scaffold plank is particularly popular for its versatility and strength. In this article, we will delve into the specifics of the weight capacity of a 7 aluminum scaffold plank, explore its applications, and discuss safety guidelines for its use.

Overview of Aluminum Scaffold Planks

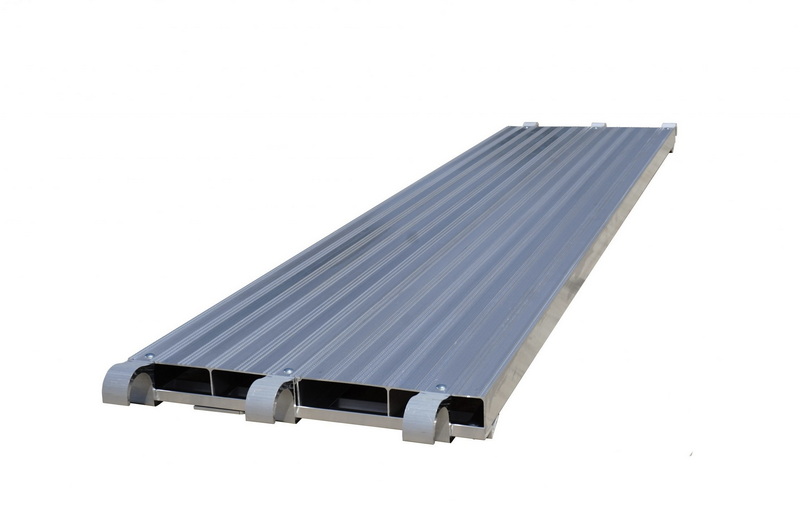

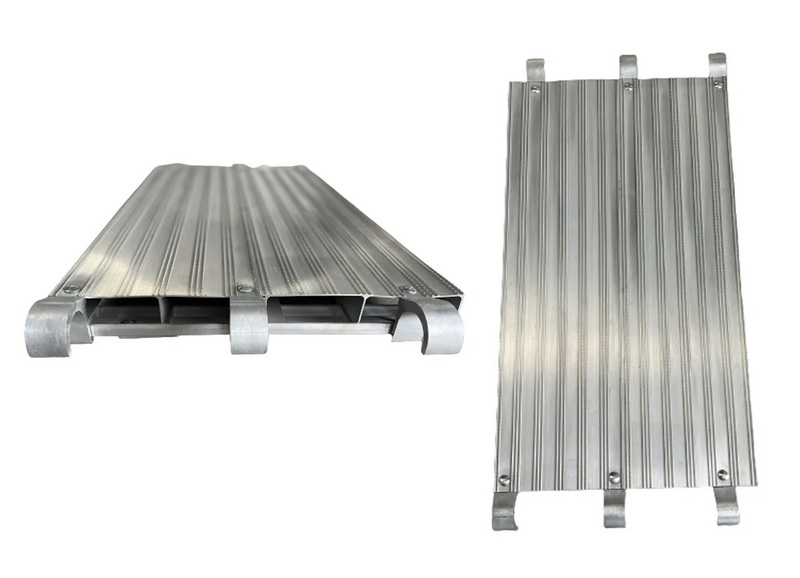

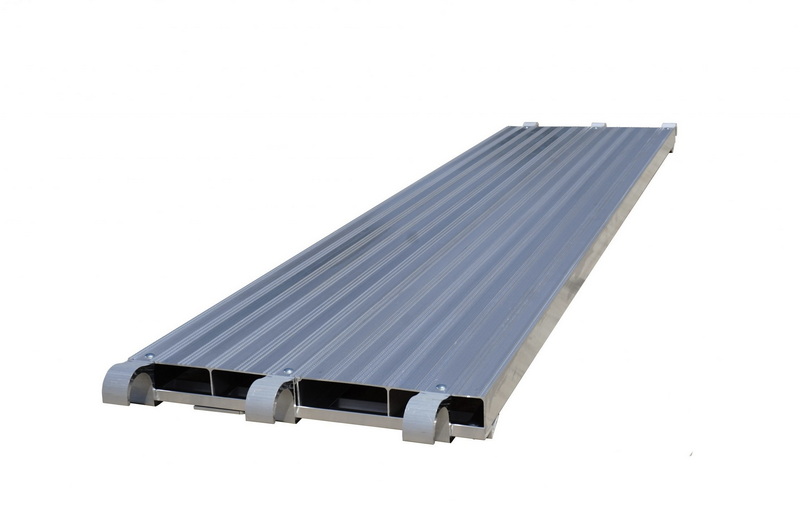

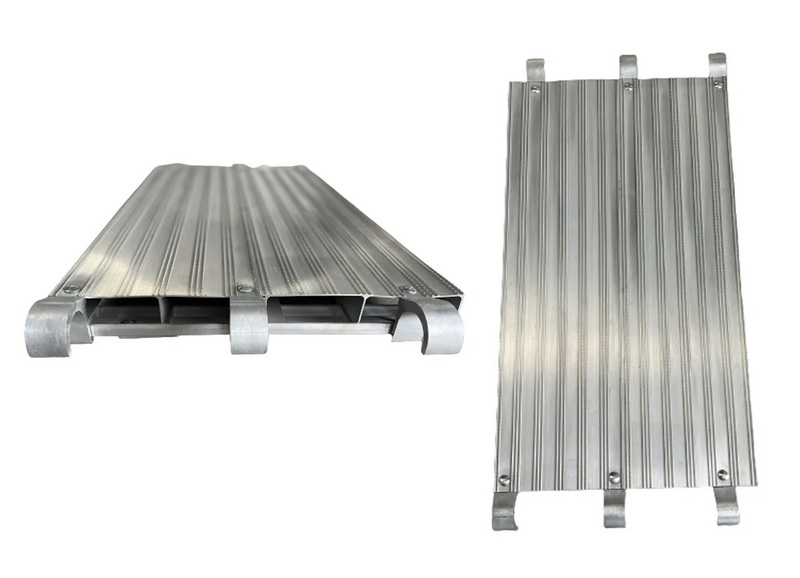

Aluminum scaffold planks are designed to provide a stable and strong platform for workers at various heights. They are made entirely of aluminum, which ensures they are lightweight and resistant to rust, making them a superior choice over traditional wooden planks. These planks come in different lengths, with the 7 aluminum scaffold plank being one of the most commonly used due to its balance between length and maneuverability.

Specifications of the 7 Aluminum Scaffold Plank

The 7 aluminum scaffold plank typically measures 7 feet in length and 19 inches in width. This size allows three planks to fit across a standard 5-foot platform, providing ample space for workers and materials. The plank is reinforced on the bottom side for added strength and features grooves on the top to remove standing water, ensuring good traction and reducing the risk of slips.

Weight Capacity

The 7 aluminum scaffold plank is rated to hold 75 pounds per square foot, making it suitable for heavy-duty applications as per OSHA standards. This capacity is crucial for ensuring that the plank can safely support workers and their equipment without compromising stability.

Applications of the 7 Aluminum Scaffold Plank

Construction and Maintenance

The 7 aluminum scaffold plank is extensively used in construction and maintenance projects. Its lightweight nature and ease of assembly make it ideal for setting up scaffolding quickly and efficiently. Whether it's for building, repairing, or painting, this plank provides a reliable platform for workers to perform their tasks safely.

Scaffolding Systems

Aluminum scaffold planks are compatible with various scaffolding systems, including supported and suspended scaffolds. They are designed with replaceable hooks and a locking mechanism to secure them firmly to the scaffolding frames, ensuring stability and safety.

Specialized Use Cases

- Bridge Maintenance: The 7 aluminum scaffold plank is often used in bridge maintenance projects due to its ability to withstand harsh weather conditions and provide a stable working surface over long spans.

- Industrial Painting: For large-scale industrial painting projects, these planks are preferred because they can support the weight of heavy painting equipment and multiple workers.

Safety Guidelines

Inspection and Maintenance

Before using any scaffold plank, it is essential to inspect it for damage or wear. This includes checking for cracks, splits, or any other defects that could compromise its structural integrity. Regular maintenance is also crucial to extend the lifespan of the plank.

Erection and Dismantling

Scaffolding should only be erected, moved, or disassembled under the supervision of competent persons. Safety equipment such as hard hats and safety glasses must be worn at all times during these processes.

Load Capacity

Never overload the scaffold. Ensure that the total weight of workers, tools, and materials does not exceed the maximum intended load capacity of the plank.

Fall Protection

Always use fall protection gear when working at heights. This includes harnesses, lanyards, and safety nets to prevent accidents.

Advantages Over Traditional Materials

Durability

Aluminum scaffold planks are more durable than wooden planks, as they are resistant to rot and insect damage. This makes them a cost-effective option in the long run.

Portability

The lightweight nature of aluminum planks makes them easier to transport and set up compared to heavier materials like steel or wood.

Environmental Resistance

Aluminum is resistant to corrosion, making it suitable for use in harsh weather conditions without the need for additional protective coatings.

Common Misconceptions

Some people believe that aluminum scaffold planks are too expensive or that they are not as strong as steel planks. However, the benefits of aluminum planks, including their durability and ease of use, often outweigh these concerns.

Conclusion

In conclusion, the 7 aluminum scaffold plank offers a reliable and safe working platform with a weight capacity of 75 pounds per square foot. Its durability, ease of use, and compatibility with various scaffolding systems make it a preferred choice in the construction industry. Always ensure that safety guidelines are followed to maximize the benefits of using these planks.

FAQ

1. What are the dimensions of a standard 7 aluminum scaffold plank?

The standard dimensions of a 7 aluminum scaffold plank are 7 feet in length and 19 inches in width.

2. What is the weight capacity of a 7 aluminum scaffold plank?

A 7 aluminum scaffold plank is rated to hold 75 pounds per square foot.

3. Are aluminum scaffold planks better than wooden planks?

Yes, aluminum scaffold planks are generally better than wooden planks due to their lightweight nature, resistance to corrosion, and longer lifespan.

4. How should aluminum scaffold planks be inspected before use?

Before use, inspect the planks for any damage such as cracks, splits, or delaminations. Ensure they are sound and in good condition.

5. Can aluminum scaffold planks be used with different types of scaffolding systems?

Yes, aluminum scaffold planks are compatible with both supported and suspended scaffolding systems.

Citations:

[1] https://scaffoldingrentalandsales.com/aluminum-scaffold-plank/

[2] https://www.youtube.com/watch?v=gJKXUuu0uO0

[3] https://brandsafway.com/uploads/files/orn202_bsl_systems_safety_guidelines_0_0.pdf

[4] https://blog.csdn.net/weixin_40289064/article/details/79669930

[5] https://dallasladder.com/products/7x19-all-aluminum-plank.html

[6] https://www.youtube.com/watch?v=FwbaCtagNrg

[7] https://www.dir.ca.gov/dosh/dosh_publications/GuideForSupportedScaffolds.pdf

[8] https://blog.csdn.net/m0_63222058/article/details/135031568

[9] https://aaitscaffold.com/products/scaffolding-planks/aluminum-plank/

[10] https://www.youtube.com/watch?v=2OhricCX38o

[11] https://www.usace.army.mil/Portals/2/docs/Safety/EM385-1-1%20Section%2022FINAL.pdf

[12] https://www.youtube.com/watch?v=xNR3yeRowto