Content Menu

● Introduction to Aluminum Plank Decking

● Advantages of Aluminum Plank Decking

● Maintenance of Aluminum Plank Decking

>> Cleaning Aluminum Plank Decking

>> Protecting Aluminum Plank Decking

>> Inspecting and Repairing Aluminum Plank Decking

>> Preventing Corrosion

>> Regular Maintenance Schedule

● Additional Tips for Aluminum Plank Decking

>> Heat Considerations

>> Installation Considerations

>> Environmental Impact

>> Cost-Effectiveness

● Advanced Maintenance Techniques

>> Using Protective Coatings

>> Regularly Cleaning Between Planks

>> Seasonal Maintenance

● Conclusion

● FAQ

>> 1. What cleaning solutions are recommended for aluminum plank decking?

>> 2. How often should I clean my aluminum plank decking?

>> 3. Can I use a pressure washer on aluminum plank decking?

>> 4. How do I protect my aluminum plank decking from UV damage?

>> 5. Can a homeowner install aluminum plank decking themselves?

● Citations:

Aluminum plank decking has become increasingly popular due to its durability, aesthetic appeal, and low maintenance requirements compared to traditional wood decking. However, to ensure that your aluminum plank decking remains in excellent condition, regular maintenance is essential. This article will guide you through the necessary steps to maintain your aluminum plank decking, including cleaning, protection, and inspection.

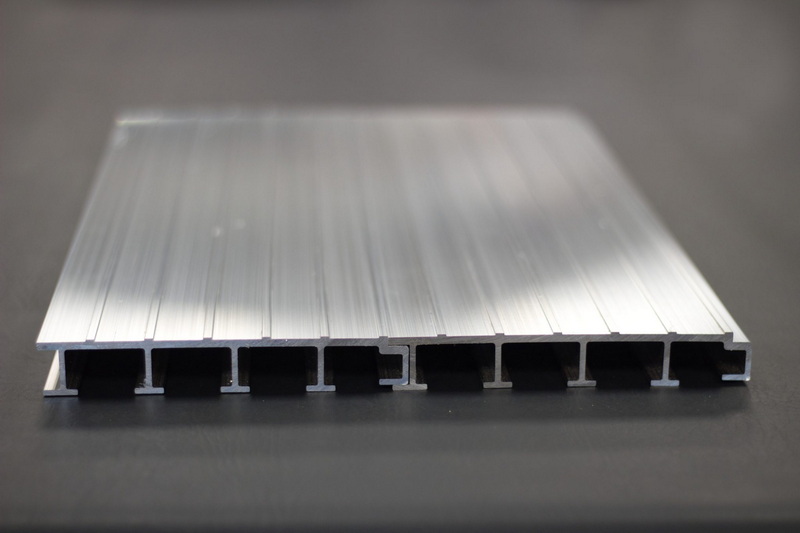

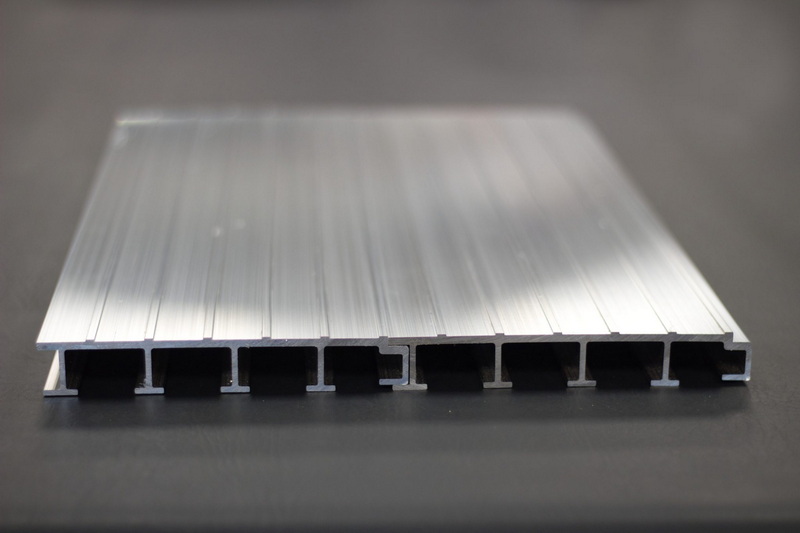

Introduction to Aluminum Plank Decking

Aluminum plank decking is known for its lightweight, non-combustible properties, making it an ideal choice for high-rise balconies and roof terraces. It is often made from recycled materials and features a durable decorative coating that provides excellent slip and wear resistance. The installation process is relatively straightforward, similar to composite or wood decking, but it requires specific tools and techniques.

Advantages of Aluminum Plank Decking

- Durability: Aluminum decking is robust and resistant to corrosion, reducing the risk of damage from weather conditions or pests.

- Low Maintenance: Unlike wood, aluminum decking does not require frequent staining or sealing, making it a cost-effective option in the long run.

- Aesthetic Appeal: It offers a sleek, modern appearance with clean lines and concealed fixings.

Maintenance of Aluminum Plank Decking

Cleaning Aluminum Plank Decking

Cleaning is a crucial part of maintaining aluminum plank decking. Here's a step-by-step guide:

1. Loosen Dirt and Debris: Use a soft-bristled brush or broom to gently sweep away loose dirt and debris from the surface of the decking.

2. Clean with Soap and Water: Mix mild dish soap with warm water. Dip a lint-free cloth or mop into the solution and wring it out thoroughly. Gently wipe down the decking, ensuring not to leave any soap residue.

3. Rinse Thoroughly: Use plain warm water to rinse the soap off the decking. Ensure all soap is removed to prevent any residue from forming.

Protecting Aluminum Plank Decking

While aluminum is naturally resistant to corrosion, protecting it from harsh chemicals and UV damage is important:

- Avoid Harsh Chemicals: Never use bleach, solvents, or abrasive cleaners, as they can damage the protective coating on the aluminum.

- UV Protection: Apply a UV-resistant coating if recommended by the manufacturer to prevent fading or discoloration.

Inspecting and Repairing Aluminum Plank Decking

Regular inspections are vital to identify any potential issues early:

- Check for Damage: Look for signs of wear, such as dents or scratches. Tighten any loose screws or fasteners.

- Contact Professionals: If you find significant damage, consider consulting a professional for repairs or replacement.

Preventing Corrosion

Although aluminum is resistant to corrosion, it can still be damaged by certain substances:

- Avoid Chemical Exposure: Be cautious with planters or pots containing fertilizers or chemicals that could erode the aluminum surface.

Regular Maintenance Schedule

Establish a routine maintenance schedule to ensure your aluminum plank decking remains in optimal condition:

- Clean Every 3-6 Months: Depending on the environment, clean your decking every three months in coastal or industrial areas and every six months elsewhere.

- Inspect Annually: Check for damage and tighten any loose fasteners annually.

Additional Tips for Aluminum Plank Decking

Heat Considerations

Aluminum decking can get hot in direct sunlight, especially if it is dark-colored. Using light colors can help mitigate this issue.

Installation Considerations

While aluminum decking is generally easy to install, it requires specific tools and techniques. Ensure you have the right screws and blades for cutting aluminum.

Environmental Impact

Aluminum plank decking is made from recycled materials, making it an environmentally friendly option. It also reduces waste by being durable and long-lasting, minimizing the need for frequent replacements.

Cost-Effectiveness

Although the initial cost of aluminum decking might be higher than some other materials, its long lifespan and low maintenance needs make it cost-effective over time. Additionally, it can increase property value due to its modern appearance and durability.

Advanced Maintenance Techniques

For those looking to enhance their maintenance routine, consider these advanced techniques:

Using Protective Coatings

Some manufacturers offer specialized coatings that can enhance the durability and appearance of your aluminum decking. These coatings can provide additional protection against UV rays and wear.

Regularly Cleaning Between Planks

Use a small brush or a specialized tool to clean between the planks, ensuring that debris does not accumulate and cause issues over time.

Seasonal Maintenance

Adjust your maintenance schedule according to the seasons:

- Spring: Clean the decking thoroughly after winter to remove any debris accumulated during the colder months.

- Summer: Regularly inspect for signs of wear and ensure that the decking is free from dirt and debris.

- Autumn: Clean leaves and debris promptly to prevent staining.

- Winter: Apply a protective coating if necessary to shield against harsh weather conditions.

Conclusion

Maintaining aluminum plank decking is straightforward and essential for preserving its appearance and longevity. Regular cleaning, protection from harsh chemicals, and inspections are key components of a maintenance routine. By following these steps and incorporating advanced techniques, you can enjoy your aluminum plank decking for years to come.

FAQ

1. What cleaning solutions are recommended for aluminum plank decking?

Mild dish soap mixed with warm water is ideal for cleaning aluminum decking. Avoid using harsh chemicals or abrasive cleaners.

2. How often should I clean my aluminum plank decking?

Clean your decking every three to six months, depending on the environmental conditions. In coastal or industrial areas, clean every three months, and in non-coastal areas, every six months.

3. Can I use a pressure washer on aluminum plank decking?

No, it is not recommended to use pressure washers or steam cleaners on aluminum decking, as they can damage the protective coating.

4. How do I protect my aluminum plank decking from UV damage?

Apply a UV-resistant coating if recommended by the manufacturer to prevent fading or discoloration.

5. Can a homeowner install aluminum plank decking themselves?

Yes, with moderate carpentry skills and the right tools, a homeowner can install aluminum decking. However, ensure you have the correct specialty blades and screws.

Citations:

[1] https://tradewarehouse.co.uk/blogs/decking/essential-tools-and-products-for-maintaining-aluminium-decking-boards

[2] https://www.youtube.com/watch?v=YAZsv_4VXz8

[3] https://huggingface.co/openbmb/VisCPM-Chat/raw/main/vocab.txt

[4] https://www.alideck.co.uk/simple-maintenance-schedule-ensure-lifetime-functionality-alideck-system/

[5] https://www.youtube.com/watch?v=4sgI6eTjmCg

[6] https://ali-deck.s3.eu-west-2.amazonaws.com/maintenance-schedule/Alideck+Maintenance+Schedule+V1.2+LU060220.pdf

[7] https://www.youtube.com/watch?v=JQxb5T4J0YI

[8] https://www.spp.co.uk/aluminium-decking-the-ultimate-guide