Content Menu

● Introduction

● What Are Expandable Aluminum Planks?

● Advantages of Expandable Aluminum Planks

● Regular Inspection: The Key to Longevity

● Cleaning and Debris Removal

● Proper Storage and Handling

● Routine Maintenance and Repairs

● Comprehensive Documentation, Tracking, and Training

● Safety Guidelines for Using Expandable Aluminum Planks

● Comparative Analysis: Expandable Aluminum vs. Fixed Planks

● Real-World Applications

>> Construction Sites

>> Maintenance and Repair

>> DIY Projects

● Additional Maintenance Tips for Expandable Aluminum Planks

>> 1. Protect Against Galvanic Corrosion

>> 2. Monitor Locking Mechanism Wear

>> 3. Avoid Overextension

>> 4. Environmental Considerations

>> 5. Professional Servicing

● Conclusion

● FAQ

>> 1. How often should I inspect expandable aluminum planks?

>> 2. What is the best way to clean expandable aluminum planks?

>> 3. How should expandable aluminum planks be stored?

>> 4. What type of lubricant should be used on the locking mechanisms?

>> 5. When should an expandable aluminum plank be replaced?

Expandable aluminum planks are versatile and durable components used in scaffolding, construction, maintenance, and various DIY projects. Their adjustability makes them ideal for different spans, but to ensure safety and longevity, proper maintenance is essential. This comprehensive guide will cover the necessary maintenance practices for expandable aluminum planks, supported by expert advice, technical data, and practical tips.

Introduction

Expandable aluminum planks offer numerous benefits, including adjustability, lightweight design, and corrosion resistance. Understanding the specific maintenance requirements can significantly extend their lifespan and ensure a safer working environment. This article provides a detailed overview of these requirements, helping you to maintain your planks in optimal condition.

What Are Expandable Aluminum Planks?

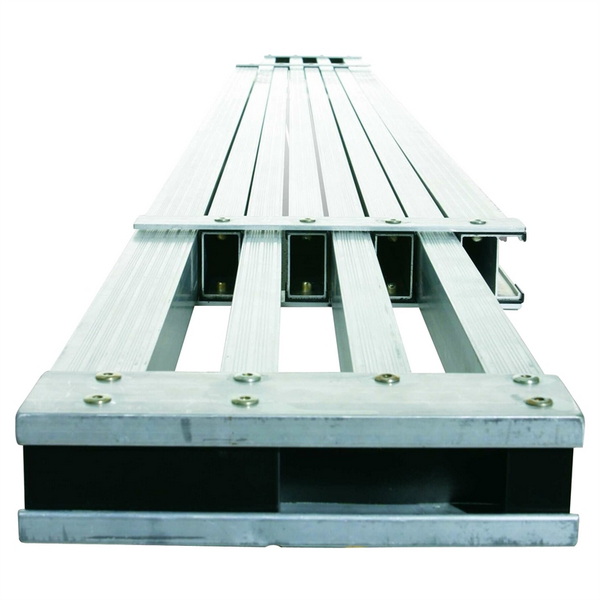

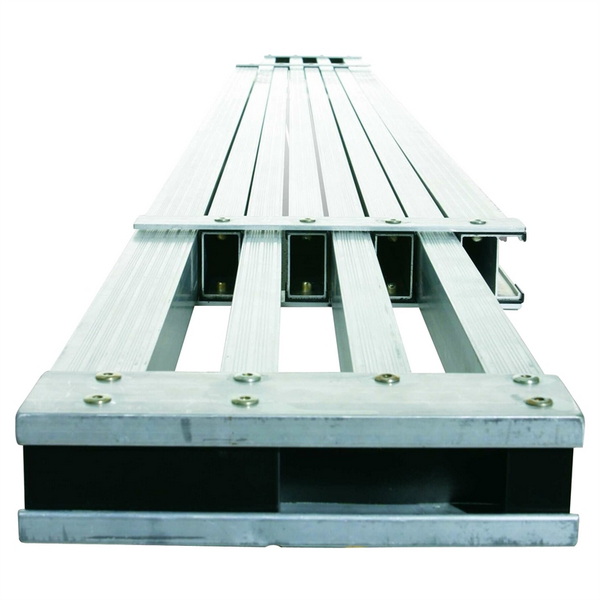

An expandable aluminum plank is an adjustable platform made primarily from high-strength aluminum alloy. These planks can be extended or retracted to fit varying distances between supports, making them highly adaptable for different job sites and tasks. They typically feature locking mechanisms to secure the plank at the desired length and slip-resistant surfaces for added safety.

Advantages of Expandable Aluminum Planks

- Adjustability: Easily adaptable to different spans.

- Lightweight: Easy to handle and transport, reducing labor costs.

- Corrosion Resistance: Aluminum does not rust, extending the lifespan of the scaffolding.

- Durability: Can withstand heavy loads and harsh weather conditions.

- Safety: Often include slip-resistant surfaces and secure locking mechanisms.

Regular Inspection: The Key to Longevity

Regular inspections are crucial for maintaining the integrity of expandable aluminum planks. These inspections should be conducted before each use and after any event that could compromise the plank's structural integrity, such as impact or overloading.

Key Inspection Points:

1. Surface Condition: Check for any signs of damage, such as dents, cracks, or bends.

2. Locking Mechanisms: Ensure that all locking mechanisms are functioning correctly and securely.

3. Welds and Connections: Inspect welds and connections for cracks or corrosion.

4. Slip-Resistant Surface: Verify that the slip-resistant surface is intact and free from debris.

5. Load Capacity: Ensure the plank meets the required load capacity for the intended use.

Cleaning and Debris Removal

Keeping expandable aluminum planks clean is essential for both safety and longevity. Regular cleaning helps remove dirt, debris, and contaminants that could weaken the structure over time.

Cleaning Steps:

1. Water and Mild Detergent: Use water and a mild detergent to clean the planks, scrubbing gently but effectively to remove built-up grime.

2. Rust Removal: If rust is present on any metal components, remove it carefully using a wire brush, then apply rust-proof paint or lubricant.

3. Air-Drying: Allow planks to air-dry completely after cleaning, as excess moisture can lead to corrosion or other damage.

Proper Storage and Handling

Proper storage and handling practices are crucial for extending the lifespan of expandable aluminum planks.

Storage Guidelines:

1. Dry Storage: Store planks in a dry, covered area to protect them from moisture and direct sunlight.

2. Horizontal Stacking: Stack planks horizontally to prevent warping or bending.

3. Organized Storage: Keep planks organized and easily accessible to facilitate quick assembly and disassembly.

4. Off the Ground: Store planks off the ground to prevent moisture absorption and corrosion.

Routine Maintenance and Repairs

Proactive maintenance and prompt repairs are vital for maintaining the integrity of expandable aluminum planks.

Maintenance Tasks:

1. Surface Treatment: Periodically apply a protective coating or anti-corrosion spray to enhance longevity.

2. Repairing Minor Damage: Use epoxy resin to fix small cracks or dents, but replace planks with significant damage.

3. Tightening Connections: Regularly inspect and tighten any loose connections to ensure stability.

4. Lubrication: Lubricate moving parts, such as locking mechanisms, to ensure smooth operation.

Comprehensive Documentation, Tracking, and Training

Maintaining detailed records of inspections, maintenance, and repairs can help identify trends and prevent future issues. Training workers on proper handling and maintenance procedures is also essential.

Documentation Practices:

1. Inspection Logs: Keep a log of all inspections, noting any damage or issues found.

2. Maintenance Records: Record all maintenance and repair activities, including dates, descriptions, and materials used.

3. Training Records: Maintain records of all training sessions, including the names of participants and topics covered.

Training Topics:

1. Safety Protocols: Ensure all personnel are familiar with safety guidelines and best practices.

2. Assembly and Disassembly: Train workers on correct setup and teardown procedures.

3. Load Limits: Educate workers on weight capacity and even load distribution.

4. Inspection Procedures: Train workers on how to properly inspect planks for damage or wear.

5. Maintenance Techniques: Teach workers how to perform routine maintenance tasks, such as cleaning and lubricating.

Safety Guidelines for Using Expandable Aluminum Planks

Following safety guidelines is critical when using expandable aluminum planks to prevent accidents and injuries.

Safety Measures:

1. Secure Setup: Ensure the plank is securely attached to the ladder or scaffolding.

2. Weight Limit: Never exceed the recommended load capacity.

3. Proper Footing: Always maintain proper footing on the plank to prevent slipping.

4. Regular Inspection: Regularly inspect the plank for any signs of wear or damage.

5. Use Safety Gear: Wear appropriate safety gear, such as hard hats and non-slip shoes.

Comparative Analysis: Expandable Aluminum vs. Fixed Planks

| Feature | Expandable Aluminum Planks | Fixed Aluminum Planks |

| Adjustability | Adjustable length for various spans | Fixed length, suitable for specific spans |

| Versatility | Highly versatile, adaptable to different projects | Less versatile, limited to specific applications |

| Storage | May require more space due to adjustable nature | Easier to store due to fixed dimensions |

| Cost | Generally more expensive | Generally less expensive |

| Maintenance | More complex due to moving parts | Simpler, fewer moving parts |

Expandable aluminum planks offer greater versatility but require more careful maintenance compared to fixed aluminum planks.

Real-World Applications

Construction Sites

Expandable aluminum planks are widely used in construction for scaffolding and providing safe platforms for workers at various heights.

Maintenance and Repair

These planks are ideal for maintenance and repair tasks, such as painting, electrical work, and plumbing, where adjustable spans are needed.

DIY Projects

Homeowners and DIY enthusiasts use expandable aluminum planks for various projects, such as roofing, siding, and window installation.

Additional Maintenance Tips for Expandable Aluminum Planks

To further enhance the durability and safety of your expandable aluminum plank, consider the following advanced maintenance tips:

1. Protect Against Galvanic Corrosion

When aluminum contacts other metals, galvanic corrosion can occur, especially in moist environments. To prevent this:

- Use insulating materials or coatings between aluminum planks and other metals.

- Avoid direct contact with steel or copper components without protective barriers.

2. Monitor Locking Mechanism Wear

Locking pins and mechanisms are critical for safety. Over time, these parts may wear or loosen:

- Replace worn pins immediately.

- Check for any deformation or corrosion on locking components.

- Ensure locking mechanisms engage fully before use.

3. Avoid Overextension

Although expandable aluminum planks are designed to extend, overextending beyond manufacturer recommendations can weaken the structure:

- Always adhere to the specified maximum extension length.

- Avoid applying uneven loads on extended sections.

4. Environmental Considerations

Exposure to extreme temperatures or chemicals can affect aluminum planks:

- Avoid prolonged exposure to harsh chemicals or solvents.

- Store planks away from direct sunlight to prevent thermal expansion stress.

5. Professional Servicing

For commercial or frequent use, consider professional servicing:

- Annual professional inspections can identify hidden issues.

- Certified technicians can perform specialized repairs and adjustments.

Conclusion

Maintaining expandable aluminum planks is essential for ensuring safety, extending their lifespan, and maximizing their versatility. Regular inspections, thorough cleaning, proper storage, and proactive repairs are key components of a comprehensive maintenance program. By following the guidelines outlined in this article, you can keep your expandable aluminum planks in optimal condition and ensure a safe working environment. Training and documentation further enhance the effectiveness of your maintenance efforts, contributing to the long-term reliability of your equipment.

FAQ

1. How often should I inspect expandable aluminum planks?

Expandable aluminum planks should be inspected before each use and after any incident that could affect their structural integrity.

2. What is the best way to clean expandable aluminum planks?

Use water and a mild detergent to clean the planks, scrubbing gently to remove dirt and grime. Allow the planks to air-dry completely after cleaning.

3. How should expandable aluminum planks be stored?

Store planks in a dry, covered area, off the ground, and stacked horizontally to prevent warping.

4. What type of lubricant should be used on the locking mechanisms?

Use a silicone-based lubricant to keep the locking mechanisms functioning smoothly and prevent corrosion.

5. When should an expandable aluminum plank be replaced?

An expandable aluminum plank should be replaced if it shows signs of significant damage, such as cracks, bends, or corrosion that could compromise its structural integrity.