Content Menu

● The Unique Demands of High-Rise Construction

● Why Choose Aluminum Pole Scaffolding System for High-Rise Projects?

>> 1. Lightweight and Easy to Handle

>> 2. High Strength-to-Weight Ratio

>> 3. Corrosion Resistance

>> 4. Quick and Easy Assembly

>> 5. Adaptability to Complex Geometries

>> 6. Enhanced Safety Features

>> 7. Wind Resistance

>> 8. Cost-Effectiveness

● Applications in High-Rise Construction

● Conclusion

● FAQ

>> 1. How does the lightweight nature of aluminum scaffolding benefit high-rise construction projects?

>> 2. What safety features are standard in an aluminum pole scaffolding system?

>> 3. Is aluminum scaffolding more expensive than steel scaffolding?

>> 4. How does aluminum scaffolding withstand high wind loads in high-rise construction?

>> 5. Can aluminum scaffolding be easily adapted to complex building designs?

● Citations:

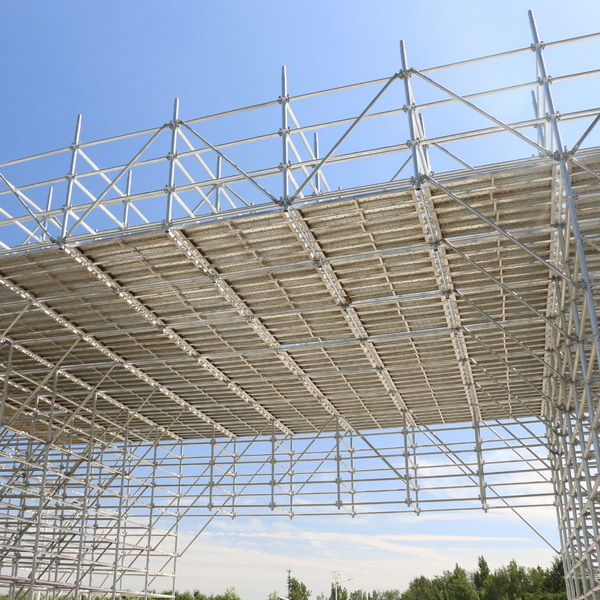

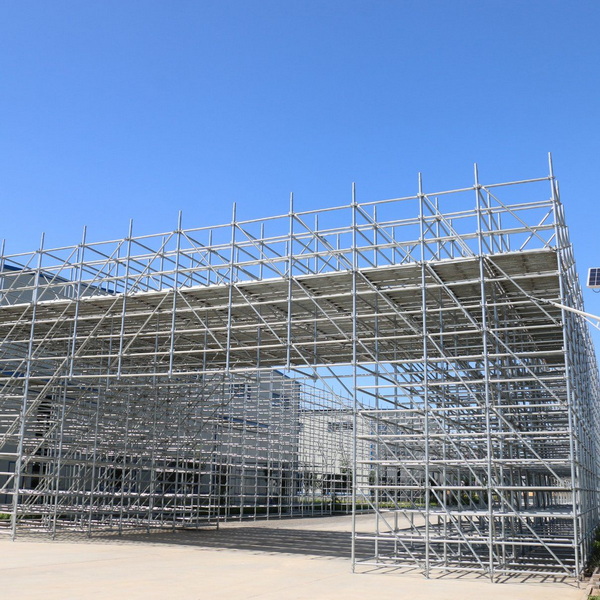

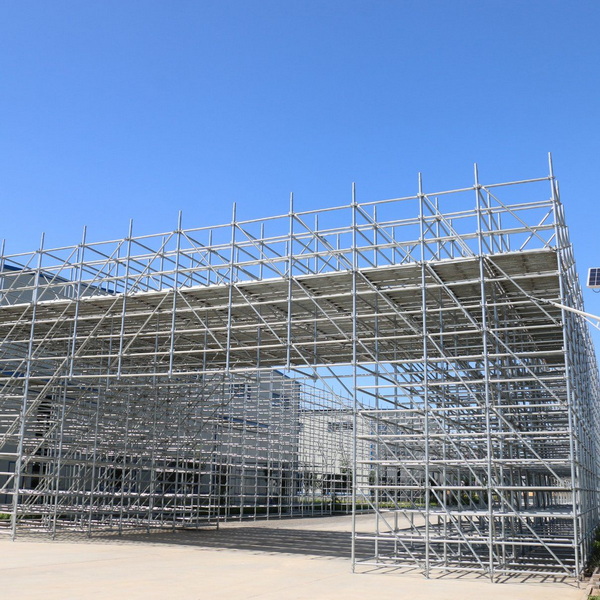

High-rise construction demands materials and systems that are not only robust and safe but also lightweight and efficient to handle. Among the various scaffolding options available, the aluminum pole scaffolding system has emerged as a premier choice for high-rise projects. Its unique combination of strength, lightness, and ease of assembly provides significant advantages over traditional steel scaffolding. This article delves into the specific benefits that make the aluminum pole scaffolding system an ideal solution for high-rise construction.

The Unique Demands of High-Rise Construction

High-rise construction presents unique challenges, including:

- Increased Height: The sheer height of these structures requires scaffolding systems that can reach extreme elevations while maintaining stability.

- Wind Loads: High-rise buildings are exposed to significant wind loads, demanding scaffolding that can withstand these forces.

- Material Handling: Moving materials up and down the structure is a logistical challenge, necessitating lightweight scaffolding components.

- Safety Concerns: Ensuring worker safety at extreme heights is paramount, requiring scaffolding systems with robust safety features.

- Assembly Efficiency: The speed and ease of assembly directly impact project timelines and labor costs, making efficient scaffolding systems essential.

Why Choose Aluminum Pole Scaffolding System for High-Rise Projects?

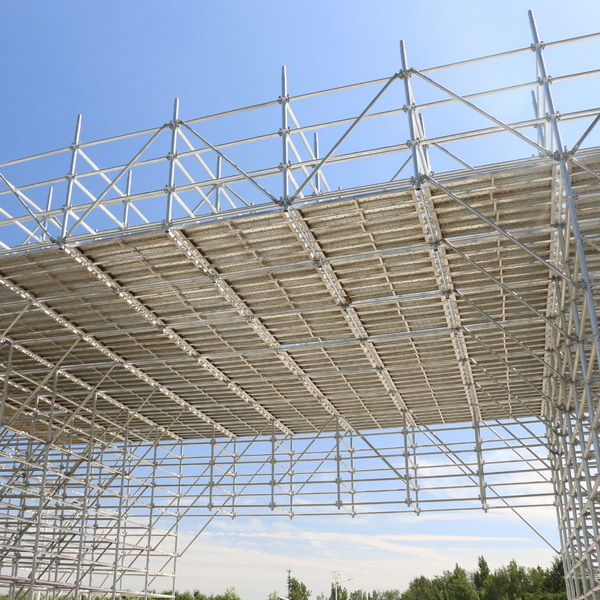

1. Lightweight and Easy to Handle

One of the most significant advantages of the aluminum pole scaffolding system is its lightweight nature. Aluminum is significantly lighter than steel, making it easier for workers to handle and maneuver the scaffolding components during assembly and disassembly.

This reduces strain and fatigue, increasing worker productivity and minimizing the risk of injuries. Furthermore, the reduced weight simplifies the process of lifting and transporting scaffolding materials to higher levels of the building.

2. High Strength-to-Weight Ratio

Despite its lightweight nature, aluminum possesses a high strength-to-weight ratio. This means that aluminum pole scaffolding systems can support substantial loads while remaining relatively light.

This is crucial in high-rise construction, where scaffolding must be able to support workers, tools, and materials at extreme heights. The aluminum pole scaffolding system provides the necessary strength and stability without adding excessive weight to the structure.

3. Corrosion Resistance

Aluminum is naturally resistant to corrosion, making it an ideal material for scaffolding used in outdoor environments. Unlike steel, which can rust and degrade over time, aluminum maintains its structural integrity even when exposed to rain, humidity, and other corrosive elements.

This corrosion resistance extends the lifespan of the aluminum pole scaffolding system, reducing the need for frequent replacements and saving on maintenance costs.

4. Quick and Easy Assembly

The aluminum pole scaffolding system is designed for quick and easy assembly, reducing labor costs and minimizing project delays. The components typically feature intuitive locking mechanisms that allow for rapid connection and disconnection.

5. Adaptability to Complex Geometries

High-rise buildings often feature complex geometries, including curves, angles, and varying heights. The aluminum pole scaffolding system is highly adaptable and can be easily configured to fit these complex shapes.

Adjustable components, such as braces and platforms, allow for flexible configurations, making it easy to adjust the scaffolding to fit specific project requirements. This versatility reduces the need for custom scaffolding solutions, saving both time and money.

6. Enhanced Safety Features

The aluminum pole scaffolding system is designed with safety as a top priority. It incorporates various safety features to protect workers at height, including:

- Non-slip Platforms: The platforms are designed with a textured surface to provide secure footing, even in wet or oily conditions.

- Guardrails and Toe Boards: These prevent falls and protect workers from dropped objects.

- Secure Locking Mechanisms: These ensure that all components are securely connected, minimizing the risk of collapse.

7. Wind Resistance

High-rise buildings are subject to strong winds, which can pose a significant challenge for scaffolding systems. The aluminum pole scaffolding system is engineered to withstand high wind loads, ensuring the safety of workers and the stability of the structure.

Properly designed and installed aluminum pole scaffolding systems can resist wind forces that would cause traditional steel scaffolding to sway or even collapse.

8. Cost-Effectiveness

While the initial investment in an aluminum pole scaffolding system may be higher than traditional steel scaffolding, the long-term cost-effectiveness is often greater. The lightweight nature of aluminum reduces labor costs, while its corrosion resistance minimizes maintenance and replacement costs.

Furthermore, the quick and easy assembly process reduces project timelines, leading to additional cost savings.

Applications in High-Rise Construction

The aluminum pole scaffolding system is used in a wide range of high-rise construction applications, including:

- Facade Installation: Providing access for installing exterior cladding, windows, and other facade elements.

- Concrete Work: Facilitating the pouring and finishing of concrete on upper floors.

- Painting and Coating: Allowing workers to safely access exterior surfaces for painting and coating applications.

- Maintenance and Repair: Providing a stable platform for performing maintenance and repair work on high-rise buildings.

Conclusion

The aluminum pole scaffolding system presents a compelling solution for high-rise construction, offering a unique combination of lightweight design, high strength, corrosion resistance, and ease of assembly. Its adaptability to complex geometries, enhanced safety features, and wind resistance make it an ideal choice for projects demanding both efficiency and safety at extreme heights. By investing in an aluminum pole scaffolding system, construction companies can enhance productivity, reduce costs, and ensure the well-being of their workers.

FAQ

1. How does the lightweight nature of aluminum scaffolding benefit high-rise construction projects?

The lightweight nature of aluminum scaffolding reduces the physical strain on workers, leading to increased productivity and fewer injuries. It also simplifies the process of lifting and transporting scaffolding materials to higher levels of the building, saving time and resources.

2. What safety features are standard in an aluminum pole scaffolding system?

Standard safety features include non-slip platforms, guardrails, toe boards, and secure locking mechanisms. These features are designed to prevent falls, protect workers from dropped objects, and ensure the overall stability of the scaffolding structure.

3. Is aluminum scaffolding more expensive than steel scaffolding?

While the initial cost of aluminum scaffolding may be higher, the long-term cost-effectiveness is often greater. The reduced labor costs, minimized maintenance, and extended lifespan of aluminum scaffolding can result in significant savings over time.

4. How does aluminum scaffolding withstand high wind loads in high-rise construction?

Aluminum scaffolding is engineered to withstand high wind loads through careful design and construction. This includes using high-strength aluminum alloys, incorporating bracing and support systems, and following strict installation guidelines to ensure the stability of the structure.

5. Can aluminum scaffolding be easily adapted to complex building designs?

Yes, aluminum scaffolding is highly adaptable and can be easily configured to fit complex building designs. Adjustable components, such as braces and platforms, allow for flexible configurations, making it easy to adjust the scaffolding to fit specific project requirements.

Citations:

[1] https://pplx-res.cloudinary.com/image/upload/v1740571215/user_uploads/CeSuPcovqtdMSCe/image.jpg

[2] https://pplx-res.cloudinary.com/image/upload/v1740571215/user_uploads/rblRsdJYvqCaenH/image.jpg