Content Menu

● Understanding KW System Scaffolding

● Key Features of KW System Scaffolding

● Why KW System Scaffolding Excels in Industrial Projects

>> 1. Superior Adaptability and Flexibility

>> 2. Enhanced Safety Features

● Core Components of KW System Scaffolding

>> 1. Site Preparation

>> 2. Assembly of Vertical Standards

>> 3. Attachment of Ledgers and Transoms

>> 4. Platform and Board Installation

>> 5. Bracing and Guardrails

>> 6. Inspection and Handover

● Chemical and Manufacturing Plants

● Power Stations

● Refineries and Industrial Shutdowns

● Infrastructure Projects

● Environmental and Regulatory Compliance

● Training and Best Practices

● Conclusion

● FAQ

>> 1. What distinguishes KW system scaffolding from traditional scaffolding?

>> 2. Is KW system scaffolding suitable for use in harsh industrial environments?

>> 3. How does KW system scaffolding improve project efficiency?

>> 4. What safety features are included in KW system scaffolding?

>> 5. Can KW system scaffolding be customized for unique industrial applications?

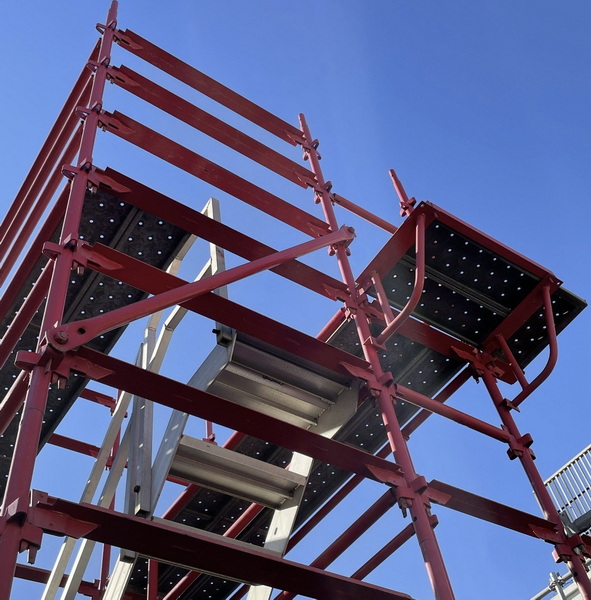

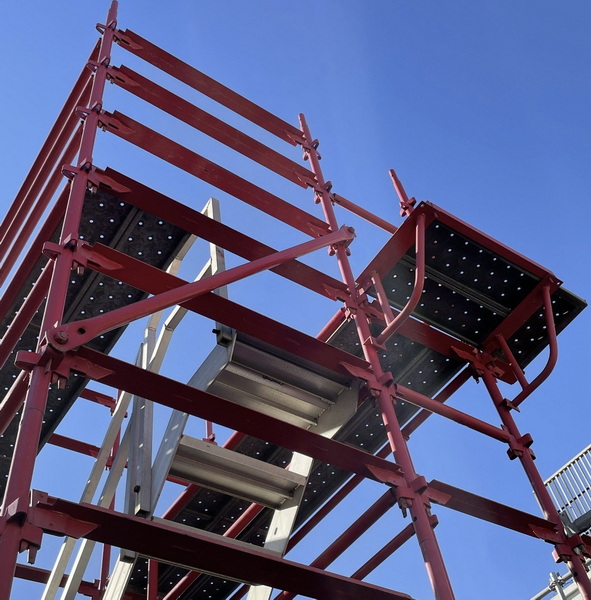

Industrial projects present unique access and safety challenges, demanding solutions that are robust, adaptable, and efficient. The KW system scaffolding commonly known as Kwikstage scaffolding-has emerged as a leading choice in the global industrial sector. Its modular design, high load capacity, and rapid assembly make it indispensable for everything from plant maintenance to large-scale infrastructure construction.

Understanding KW System Scaffolding

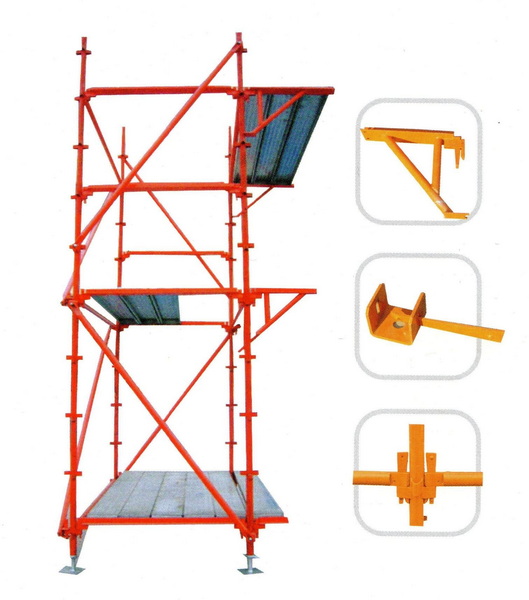

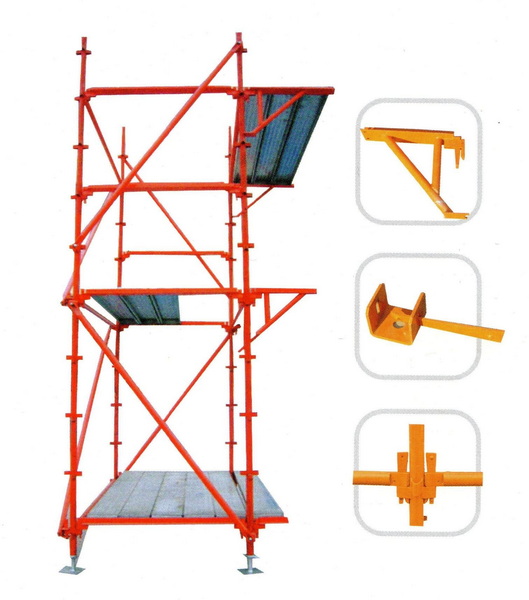

KW system scaffolding is a modular, prefabricated scaffolding solution engineered for rapid assembly and disassembly. It uses standardized components-vertical standards, horizontal ledgers, transoms, braces, and steel boards-that interlock securely via wedge or cup-lock mechanisms. This design eliminates the need for loose fittings, making the system safer and more efficient for large-scale industrial use.

Key Features of KW System Scaffolding

- Modular Design: Prefabricated components allow for flexible configurations to suit complex industrial structures.

- High Load Capacity: Engineered for heavy-duty applications, supporting substantial weights typical in industrial settings.

- Quick Assembly and Dismantling: Wedge-lock or cup-lock connections enable fast setup and breakdown, reducing labor time.

- Durable Materials: Made from high-grade steel, often hot-dip galvanized for corrosion resistance and longevity.

- Safety Compliance: Designed to meet or exceed international safety standards, with built-in guardrails, toe boards, and secure platforms.

Why KW System Scaffolding Excels in Industrial Projects

1. Superior Adaptability and Flexibility

- Industrial sites-such as chemical plants, power stations, refineries, and manufacturing facilities-often feature complex layouts, tight spaces, and unique access challenges. The modular nature of KW system scaffolding allows it to be tailored to fit any structure, whether it's a straight façade, curved surface, or irregular framework. This flexibility means that contractors can create safe working platforms around tanks, silos, piping, and machinery, even in confined or awkward spaces.

- Industrial projects require scaffolding that can safely support workers, tools, and heavy materials. KW system scaffolding is engineered for high load-bearing strength, with standards and ledgers designed to distribute weight evenly and maintain structural integrity even under demanding conditions. This makes it suitable for supporting heavy mechanical equipment, large work crews, and storage of materials at height.

- Time is critical in industrial projects, especially during plant shutdowns and maintenance windows. The wedge-lock or cup-lock mechanism of KW system scaffolding enables swift assembly and dismantling-often without the need for specialized tools-minimizing downtime and labor costs. Experienced crews can erect large, multi-level scaffolds in a fraction of the time required by traditional tube-and-coupler systems.

2. Enhanced Safety Features

Industrial environments present significant safety risks, including working at height, exposure to hazardous materials, and heavy machinery. KW system scaffolding incorporates safety features such as:

- Guardrails and toe boards

- Non-slip steel platforms

- Secure locking mechanisms

- Diagonal and horizontal bracing for stability

All components are manufactured to rigorous standards and are regularly inspected to ensure ongoing safety compliance. The standardized nature of the system also reduces the risk of assembly errors, further enhancing site safety.

Industrial projects often take place outdoors or in harsh environments. KW system scaffolding components are typically hot-dip galvanized or powder-coated, providing excellent resistance to corrosion, chemicals, and extreme weather. This durability ensures the system remains safe and functional over many years of heavy use, even in coastal, chemical, or high-humidity environments.

While the initial investment in KW system scaffolding may be higher than traditional tube-and-coupler systems, its reusability, durability, and reduced assembly time lead to significant cost savings over the lifecycle of multiple projects. The modular components can be quickly redeployed for different tasks, maximizing return on investment.

Core Components of KW System Scaffolding

Component | Function | Typical Material |

Standards | Vertical supports, main load-bearing elements | High-strength steel |

Ledgers | Horizontal connectors between standards | Steel |

Transoms | Support scaffold boards and platforms | Steel angle iron |

Braces (diagonal/horizontal) | Enhance stability and prevent sway | Steel |

Steel Boards/Platforms | Provide safe working surfaces | Galvanized steel |

Base Jacks/Plates | Distribute load and level scaffold | Steel |

Toe Boards | Prevent tools/materials from falling | Steel or timber |

Guardrails | Protect workers from falls | Steel |

1. Site Preparation

- Inspect and clear the area where scaffolding will be erected.

- Ensure the ground is level and capable of supporting the scaffold's weight.

- Place base plates or adjustable jacks as the foundation.

2. Assembly of Vertical Standards

- Insert standards into base jacks.

- Align standards according to the scaffold design, ensuring correct spacing.

3. Attachment of Ledgers and Transoms

- Connect horizontal ledgers to the standards using wedge or cup-lock mechanisms.

- Install transoms to support the working platforms.

4. Platform and Board Installation

- Place steel boards or platforms securely on transoms.

- Ensure platforms are level and free of gaps.

5. Bracing and Guardrails

- Add diagonal and horizontal braces for stability.

- Install guardrails and toe boards at all working levels for safety.

6. Inspection and Handover

- Conduct a thorough inspection to ensure all connections are secure.

- Check for compliance with safety regulations before use.

Chemical and Manufacturing Plants

KW system scaffolding is ideal for maintenance, inspection, and repair tasks in chemical and manufacturing plants, where complex piping and machinery require adaptable access solutions.

Power Stations

The system's load capacity and flexibility make it suitable for turbine maintenance, boiler access, and structural repairs in power generation facilities.

Refineries and Industrial Shutdowns

During planned shutdowns, time is critical. KW system scaffolding's rapid assembly and dismantling help minimize downtime and maintain project schedules.

Infrastructure Projects

From bridge construction to tunnel maintenance, KW system scaffolding provides stable platforms for heavy-duty work, even on uneven or irregular surfaces.

- Regular Inspection: Check for damage, corrosion, or wear before each use.

- Cleaning: Remove debris and contaminants after each project.

- Storage: Store in a dry, covered area to prevent rust and prolong lifespan.

- Surface Treatment: Hot-dip galvanizing or powder coating enhances resistance to harsh environments.

Environmental and Regulatory Compliance

KW system scaffolding is designed to comply with international safety and environmental standards, including:

- OSHA (Occupational Safety and Health Administration, USA)

- EN 12810/12811 (European Standards)

- AS/NZS 1576 (Australia/New Zealand)

- BS 1139 (British Standard)

Adhering to these standards ensures not only the safety of workers but also the sustainability and minimal environmental impact of scaffolding operations.

Training and Best Practices

Proper training is essential for safe and efficient use of KW system scaffolding. Leading manufacturers and rental companies offer certification programs and on-site training. Best practices include:

- Always follow the manufacturer's assembly instructions.

- Never exceed the rated load capacity.

- Use all required safety accessories (guardrails, toe boards, etc.).

- Inspect all components before and after use.

- Keep platforms clear of debris and tools.

Conclusion

KW system scaffolding stands out as the ideal solution for industrial projects due to its adaptability, strength, safety, and efficiency. Its modular design allows for rapid configuration and reconfiguration, while its robust construction ensures safety and reliability even in the most demanding environments. By investing in KW system scaffolding, industrial operators gain a cost-effective, long-lasting, and versatile access solution that meets the highest standards of safety and productivity. Whether for maintenance, shutdowns, or new construction, KW system scaffolding delivers unmatched value and performance.

FAQ

1. What distinguishes KW system scaffolding from traditional scaffolding?

KW system scaffolding uses modular, prefabricated components with wedge or cup-lock connections, making it faster and safer to assemble than traditional tube-and-coupler scaffolding. Its design reduces the risk of loose fittings and enhances overall stability.

2. Is KW system scaffolding suitable for use in harsh industrial environments?

Yes, KW system scaffolding is typically made from high-grade steel and finished with hot-dip galvanizing or powder coating, providing excellent resistance to corrosion, chemicals, and extreme weather, making it ideal for harsh industrial settings.

3. How does KW system scaffolding improve project efficiency?

Its modular design allows for rapid assembly and dismantling, reducing labor time and costs. The system's adaptability also means it can be reused across multiple projects, further enhancing efficiency and ROI.

4. What safety features are included in KW system scaffolding?

The system includes built-in guardrails, toe boards, non-slip platforms, and secure locking mechanisms. All components are manufactured to high safety standards and are regularly inspected to ensure ongoing compliance.

5. Can KW system scaffolding be customized for unique industrial applications?

Absolutely. The modular components can be configured to fit complex structures, irregular shapes, and varying heights, making KW system scaffolding one of the most versatile solutions for industrial projects.