Content Menu

● Understanding Traditional Scaffolding

● The Advantages of PERI System Scaffolding

>> Modular Design and Self-Locking Connections

>> Faster Assembly and Reduced Labor Costs

>> Enhanced Safety Features

>> Greater Adaptability

>> High Load-Bearing Capacity

● The PERI UP System: A Closer Look

● Applications of PERI System Scaffolding

● Cost and Efficiency

● Challenges and Considerations

● Conclusion

● FAQ

>> 1. What is PERI system scaffolding?

>> 2. How does PERI system scaffolding differ from traditional scaffolding?

>> 3. What are the key features of the PERI UP system?

>> 4. What are the benefits of using PERI system scaffolding?

>> 5. Is PERI system scaffolding suitable for all types of construction projects?

● Citations:

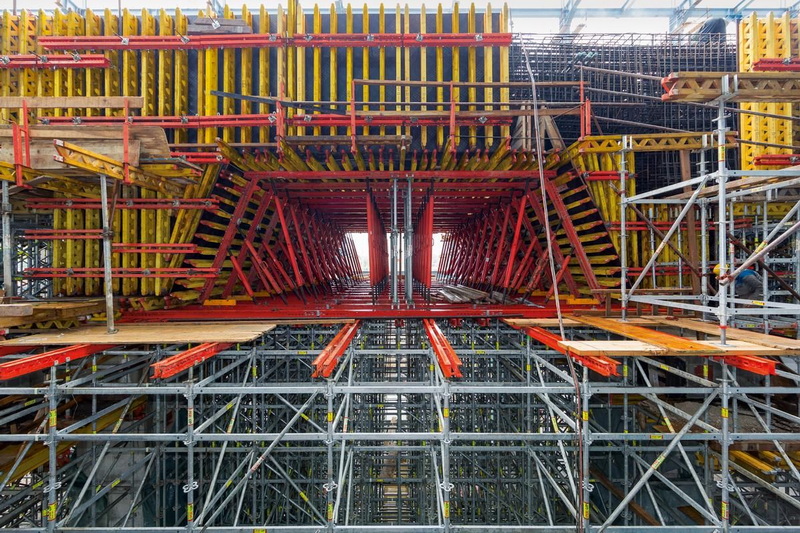

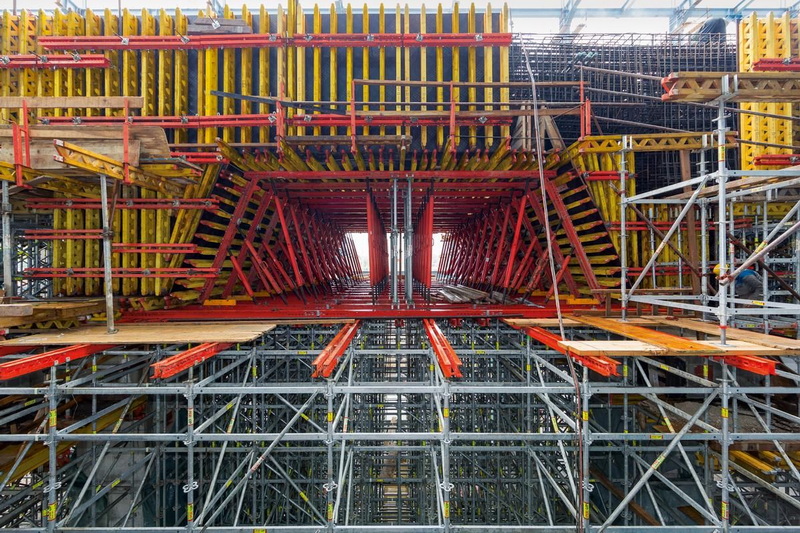

Scaffolding is an integral part of construction, maintenance, and renovation projects, providing temporary structures to support workers and materials. While traditional scaffolding has been the industry standard for decades, PERI system scaffolding represents a significant leap forward in terms of safety, efficiency, and adaptability. This article explores the distinct advantages of PERI system scaffolding over traditional methods, examining its features, benefits, and impact on construction projects.

Understanding Traditional Scaffolding

Traditional scaffolding typically consists of tube and coupler systems, requiring manual assembly and disassembly with numerous small parts and connections. This method can be labor-intensive, time-consuming, and potentially hazardous due to the complexity of the assembly process and the risk of errors. The primary characteristics of traditional scaffolding include:

- Manual Assembly: Requires significant manual effort and skill to assemble and disassemble.

- Numerous Components: Consists of many individual parts, increasing the risk of lost or misplaced components.

- Time-Consuming: Slower to erect and dismantle compared to system scaffolding.

- Higher Labor Costs: Requires a larger workforce, resulting in increased labor expenses.

- Lower Adaptability: Less flexible in adapting to complex geometries and site conditions.

The Advantages of PERI System Scaffolding

PERI system scaffolding offers several key advantages that address the limitations of traditional scaffolding. These benefits include:

- Modular Design: Pre-engineered components that easily fit together, streamlining the assembly process[1].

- Self-Locking Connections: Secure connections that reduce the risk of errors and enhance safety[1].

- Faster Assembly: Quicker erection and dismantling times, improving project timelines[8].

- Reduced Labor Costs: Requires fewer workers for assembly, lowering labor expenses[5].

- Increased Safety: Enhanced safety features, such as integrated guardrails and non-slip surfaces, minimize the risk of accidents[1].

- Greater Adaptability: Flexible configurations that can accommodate complex site conditions and geometries[8].

- Higher Load-Bearing Capacity: Robust construction that can support heavier loads, ensuring stability and safety[1].

Modular Design and Self-Locking Connections

PERI system scaffolding features pre-engineered main components designed for easy assembly and self-locking ledger connections[1]. This modular design allows for quick and efficient erection, reducing the time and labor required compared to traditional scaffolding. The self-locking connections ensure that all components are securely fastened, minimizing the risk of errors and enhancing overall safety[1].

Faster Assembly and Reduced Labor Costs

One of the most significant advantages of PERI system scaffolding is its faster assembly and dismantling times[8]. The modular design and self-locking connections enable workers to erect and dismantle the scaffold more quickly, reducing labor costs and improving project timelines[5]. In some cases, PERI system scaffolding can be erected safely with teams of two or three, compared to the four to six workers typically required for traditional ringlock systems[2][5].

Enhanced Safety Features

PERI system scaffolding incorporates numerous safety features that minimize the risk of accidents and injuries. These features include:

- Integrated Guardrails: Provide a secure barrier to prevent falls[1].

- Non-Slip Surfaces: Offer improved traction and reduce the risk of slips and trips[1].

- High-Visibility Toe Boards: Yellow toe boards enhance visibility and help workers identify and mitigate safety risks[1].

- Tie-Off Points: Approved tie-off points on ledgers allow for 100% tie-off, eliminating pendulum falls[1].

Greater Adaptability

PERI system scaffolding is highly adaptable and can be configured to accommodate complex site conditions and geometries[8]. The components fit in all directions on a 25-centimeter grid, allowing for easy adjustment around obstacles and any site configuration[1]. This flexibility eliminates the need for cutting wood to fit and install as decking or toeboards, as PERI system scaffolding components are sized for flexible configurations[2].

High Load-Bearing Capacity

PERI system scaffolding is designed to support heavier loads than traditional scaffolding, ensuring stability and safety. The galvanized steel decks are capable of bearing high loads and have a non-slip surface, providing a secure working platform[1]. This high load-bearing capacity makes PERI system scaffolding suitable for a wide range of applications, including heavy construction and industrial projects.

The PERI UP System: A Closer Look

The PERI UP system is a modular scaffolding system that exemplifies the advantages of PERI system scaffolding over traditional methods. The PERI UP system features:

- Gravity Lock Technology: Maximizes safety and speed during the assembly process[1].

- PERI Decks: Instantly lock into place without the use of tools or consumables and have a perforated, anti-slip surface[1][6].

- Versatile Fit: Components fit in all directions on a 25-centimeter grid for easy adjustment around any obstacle and site configuration[1][8].

- Tie-Off Points: Approved tie-off points on ledgers allow for 100% tie-off, eliminating pendulum falls[1].

The PERI UP system's flexibility, safety, and efficiency make it a preferred choice for construction projects worldwide.

Applications of PERI System Scaffolding

PERI system scaffolding is suitable for a wide range of applications, including:

- Facade Scaffolding: Modular and frame design enables fast, safe, and simple assembly for use on facades[4].

- Reinforcement Scaffolding: Specially designed for reinforcement, formwork, and concreting work[4].

- Suspended Scaffolding: Temporary and safe working platforms can be realized with PERI UP Suspended Scaffolding[4].

- Shoring Towers: Core components facilitate the assembly of modular shoring towers for a wide range of shoring tasks[4].

- Stair Solutions: Combine with core components for numerous fields of application with high safety standards[4].

- Protection Scaffolds: Developed to shield construction operations and construction sites from external atmospheric influence[4].

Cost and Efficiency

While the initial investment in PERI system scaffolding may be higher than traditional scaffolding, the long-term cost savings and efficiency gains can be significant. The reduced labor costs, faster assembly times, and increased safety can result in substantial savings over the life of a project[2]. Additionally, the reusability of PERI system scaffolding components allows materials to be cycled through various projects, reducing environmental impact and driving productivity[5].

Challenges and Considerations

Despite its numerous advantages, there are some challenges and considerations associated with PERI system scaffolding:

- Initial Investment: The upfront cost of PERI system scaffolding can be higher than traditional scaffolding.

- Training: Workers need to be properly trained in the correct assembly and disassembly techniques for PERI system scaffolding.

- Compatibility: PERI system scaffolding components are not compatible with other systems, so it is essential to use only genuine PERI components to ensure safety and performance[1].

Conclusion

PERI system scaffolding offers significant advantages over traditional scaffolding in terms of safety, efficiency, and adaptability. Its modular design, self-locking connections, faster assembly times, reduced labor costs, and enhanced safety features make it a preferred choice for a wide range of construction projects. While there are some challenges and considerations associated with PERI system scaffolding, the long-term cost savings and efficiency gains can be substantial. By investing in PERI system scaffolding and ensuring proper training and usage, construction companies can create safer and more productive working environments.

FAQ

1. What is PERI system scaffolding?

PERI system scaffolding is a modular scaffolding system designed for quick assembly, enhanced safety, and adaptability, using pre-engineered components and self-locking connections[1].

2. How does PERI system scaffolding differ from traditional scaffolding?

PERI system scaffolding offers faster assembly, reduced labor costs, increased safety, and greater adaptability compared to traditional scaffolding[5][8].

3. What are the key features of the PERI UP system?

The key features of the PERI UP system include gravity lock technology, PERI decks, versatile fit, and tie-off points[1].

4. What are the benefits of using PERI system scaffolding?

The benefits of using PERI system scaffolding include improved safety, reduced labor costs, faster assembly times, and greater adaptability[2][5][8].

5. Is PERI system scaffolding suitable for all types of construction projects?

PERI system scaffolding is suitable for a wide range of construction projects, including facade scaffolding, reinforcement scaffolding, suspended scaffolding, shoring towers, stair solutions, and protection scaffolds[4].

Citations:

[1] https://www.axiosindustrial.com/industrial-services/scaffolding/peri-up-flex-modular-scaffold-system/

[2] https://www.ameco.com/news-insights/benefits-of-peri-scaffolding-5-ways-amecos-integrated-scaffolding-solution-lowers-overall-cost/

[3] https://www.peri.no/dam/jcr:4b81d03e-5825-49cc-96b9-400c02fb4622/periup-and-variokit-product-brochure.pdf

[4] https://www.peri.com/en/competences/scaffolding-systems.html

[5] https://constructiondigital.com/built-environment/peri-brings-integrated-scaffold-solutions-to-construction

[6] https://www.linkedin.com/pulse/conventional-scaffolding-has-been-laid-flat-peri-up-way-mulligan

[7] https://www.peri-usa.com/products/products-overview/scaffolding-homepage.html

[8] https://www.axiosindustrial.com/blogs/the-benefits-of-peri-scaffolding-parts