Content Menu

● The Rise of the 32 Aluminum Plank in Roofing

● Technical Specifications of the 32 Aluminum Plank

● Key Advantages for Roofing Applications

>> Lightweight Yet Strong

>> Corrosion and Weather Resistance

>> Energy Efficiency

>> Long Lifespan

>> Design Flexibility

● Weather Resistance and Longevity

>> Performance in Extreme Conditions

>> Corrosion Resistance in Coastal and Industrial Areas

● Installation Process and Best Practices

>> Step-by-Step Installation

● Maintenance and Care for Aluminum Roofing

>> Routine Inspection and Cleaning

>> Professional Maintenance Tips

● Environmental and Cost Benefits

>> Sustainability

>> Cost-Effectiveness

● Real-World Performance and Case Studies

>> Residential Roofing

>> Commercial and Industrial Projects

>> Case Study

● Safety Considerations When Using the 32 Aluminum Plank

>> Working Safely at Heights

● Common Mistakes and How to Avoid Them

>> Pitfalls in Aluminum Roofing Installation

● User Experiences and Testimonials

>> What Do Real Users Say?

● Conclusion

● FAQ

>> 1. What is the weight and load capacity of a 32 aluminum plank?

>> 2. How long does a 32 aluminum plank roof last?

>> 3. Is the 32 aluminum plank suitable for coastal or industrial environments?

>> 4. What maintenance does a 32 aluminum plank roof require?

>> 5. Does a 32 aluminum plank help with energy efficiency?

Aluminum has long been recognized as a premier material for roofing applications, and the 32 aluminum plank stands out as a top choice for professionals and homeowners alike. Its unique combination of strength, durability, lightweight design, and weather resistance makes it especially well-suited for demanding roofing projects. This comprehensive guide explores why the 32 aluminum plank is ideal for roofing, covering technical specifications, installation, maintenance, real-world performance, and more.

The Rise of the 32 Aluminum Plank in Roofing

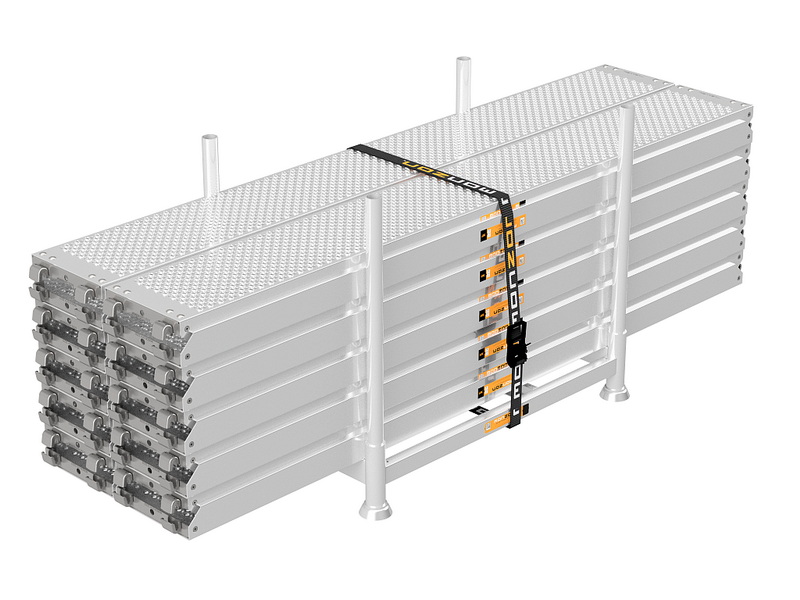

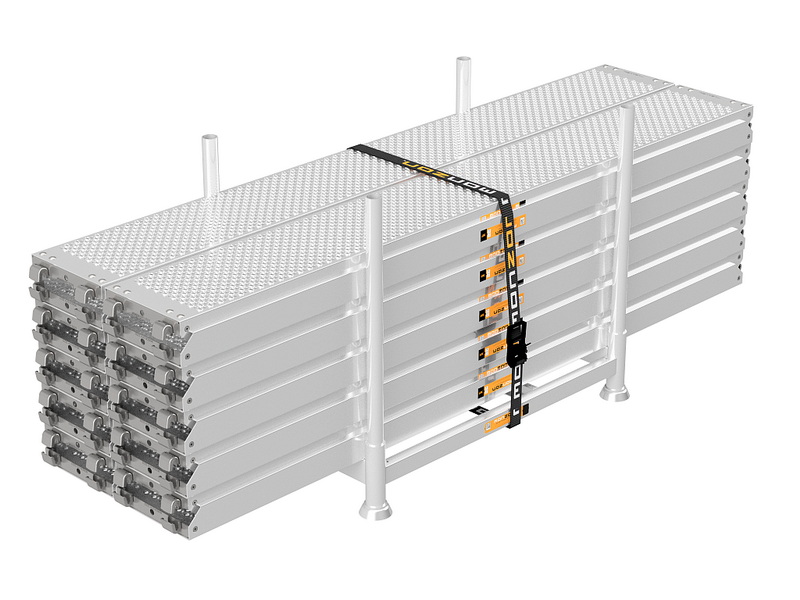

The 32 aluminum plank has become increasingly popular in the roofing industry due to its ability to meet the rigorous demands of both residential and commercial projects. Its 32-foot length allows for fewer seams, reducing potential leak points and increasing installation efficiency. With a load capacity of 500 lbs and features such as slip-resistant decking and ergonomic handles, the 32 aluminum plank is engineered for safety and ease of use, making it a staple on job sites where quality and reliability are paramount.

Technical Specifications of the 32 Aluminum Plank

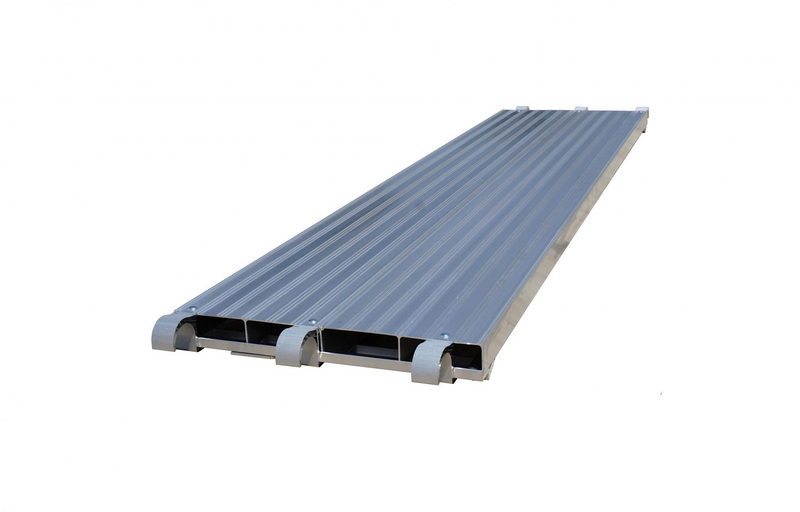

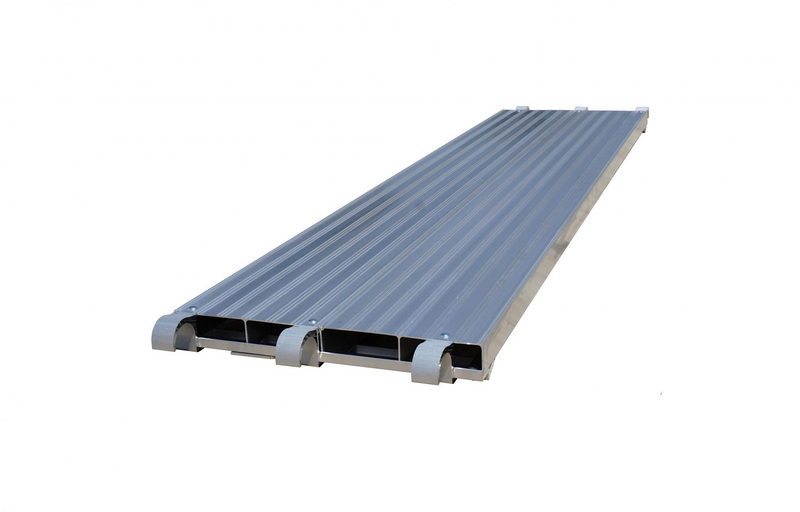

Understanding the technical features of the 32 aluminum plank is crucial for appreciating its advantages in roofing:

- Length: 32 feet

- Width: 12 inches

- Load Capacity: 500 lbs (supports two people)

- Material: High-strength aluminum alloy

- Weight: 160 lbs

- Decking: Slip-resistant

- Handles: Molded ergonomic for easy grip

- Reinforcement: Web braces for added strength

- Handrail System: Optional modular for enhanced safety

- Compliance: Meets OSHA and ANSI standards

Key Features of the 32 Aluminum Plank:

| Feature | Specification |

| Length | 32 feet |

| Width | 12 inches |

| Load Capacity | 500 lbs |

| Material | Aluminum alloy |

| Weight | 160 lbs |

| Decking | Slip-resistant |

| Handles | Ergonomic, molded |

| Reinforcement | Web braces |

| Handrail System | Optional |

| Compliance | OSHA, ANSI |

Key Advantages for Roofing Applications

Lightweight Yet Strong

Aluminum is among the lightest metals used in construction, making the 32 aluminum plank easy to transport, lift, and install-an important benefit when working at heights or on steep pitches. Despite its light weight, the plank's high-strength alloy and reinforced design allow it to support substantial loads, making it safe for workers and equipment.

Corrosion and Weather Resistance

A defining feature of the 32 aluminum plank is its natural resistance to corrosion. Aluminum forms a protective oxide layer that shields it from rust and degradation, even in coastal or industrial environments where salt and pollutants can quickly destroy other metals. This makes the plank ideal for roofs exposed to harsh weather, heavy rain, or sea air.

Energy Efficiency

Aluminum's high reflectivity means it deflects solar radiation, helping to keep buildings cooler in hot climates and reducing energy costs for air conditioning. This is particularly advantageous for large commercial roofs or homes in sunny regions.

Long Lifespan

Properly installed and maintained aluminum roofing systems can last 50 years or more, far outlasting traditional materials like asphalt shingles. The 32 aluminum plank's durability translates to fewer repairs and replacements over the life of the roof.

Design Flexibility

The malleability of aluminum allows the 32 aluminum plank to be formed into various profiles and integrated with different roofing systems, including standing seam, corrugated, and flat panel designs. This versatility supports both functional and aesthetic requirements.

Weather Resistance and Longevity

Performance in Extreme Conditions

The 32 aluminum plank excels in environments where other materials struggle. It resists:

- UV Radiation: Aluminum does not degrade or lose strength under prolonged sunlight.

- Temperature Fluctuations: Maintains structural integrity in both extreme heat and cold.

- High Winds: Properly installed aluminum roofing can withstand hurricane-force winds without damage.

- Heavy Rain and Snow: The smooth, non-porous surface sheds water efficiently and resists buildup of snow and ice.

Corrosion Resistance in Coastal and Industrial Areas

Aluminum's natural oxide layer makes it especially suitable for roofs near the ocean or in areas with acidic rain or industrial pollutants. Unlike steel, which can rust and weaken, the 32 aluminum plank remains structurally sound and visually appealing over decades.

Installation Process and Best Practices

Step-by-Step Installation

Installing a 32 aluminum plank for roofing is straightforward but requires attention to detail for maximum performance and safety:

1. Preparation: Inspect the roof deck, ensure it is solid and level. Install appropriate underlayment (such as high-temp asphalt felt) for moisture protection.

2. Panel Placement: Position the 32 aluminum plank square with the eave and rake. Ensure panels do not extend beyond the fascia.

3. Fastening: Use corrosion-resistant screws, typically spaced 12-24 inches apart, depending on wind uplift requirements.

4. Sealing: Apply butyl sealant tape at panel overlaps and joints to prevent leaks.

5. Joining Panels: Overlap panels according to manufacturer guidelines, usually 6-12 inches, and secure with additional fasteners and sealant.

6. Flashing and Trim: Install flashing from the bottom up, lapping upper pieces over lower ones to direct water away from seams.

7. Final Inspection: Check for secure fastening, proper alignment, and effective sealing. Test for water tightness if possible.

Maintenance and Care for Aluminum Roofing

Routine Inspection and Cleaning

While the 32 aluminum plank is low maintenance, regular care extends its lifespan:

- Inspect Twice a Year: Look for dents, scratches, loose fasteners, or debris buildup-especially after severe weather.

- Clean Gently: Use a soft brush and mild detergent to remove dirt, algae, or moss. Avoid harsh chemicals and abrasive tools.

- Clear Gutters and Downspouts: Prevent water pooling and ensure proper drainage.

- Address Minor Damage Promptly: Repair dents or scratches to prevent water infiltration and maintain the plank's protective coating.

Professional Maintenance Tips

- Sealant Application: Reapply roof sealant every few years, especially at seams and fastener points, to maintain water resistance.

- Repainting: If the finish fades or chalks, consider repainting with a compatible coating to restore appearance and protection.

- Avoid Walking on Panels: Minimize foot traffic to prevent dents, or use walk pads if frequent access is needed.

Environmental and Cost Benefits

Sustainability

Aluminum is one of the most sustainable building materials available:

- 100% Recyclable: The 32 aluminum plank can be recycled indefinitely without loss of quality, reducing landfill waste and demand for new raw materials.

- Low Carbon Footprint: Recycling aluminum uses only about 5% of the energy required to produce new aluminum.

- Longevity: The long service life of aluminum roofing minimizes the need for replacement, further reducing environmental impact.

Cost-Effectiveness

While the upfront cost of a 32 aluminum plank may be higher than asphalt or wood, its durability, minimal maintenance, and energy-saving properties yield significant savings over time. Fewer repairs, lower energy bills, and a lifespan exceeding 50 years make it a wise investment.

Real-World Performance and Case Studies

Residential Roofing

Homeowners in coastal and hurricane-prone regions have adopted the 32 aluminum plank for its resilience against salt air, wind, and rain. Many report decades of leak-free, low-maintenance performance, even in challenging climates.

Commercial and Industrial Projects

Large commercial buildings benefit from the 32 aluminum plank's long span, reducing the number of seams and installation time. Its strength supports heavy equipment and foot traffic during maintenance, while its reflectivity contributes to lower cooling costs.

Case Study

A roofing contractor in North Myrtle Beach installed .032 aluminum panels on a beachfront home. The installation process was efficient due to the plank's length and light weight, and the finished roof withstood multiple hurricane seasons without leaks or corrosion. The homeowner noted cooler indoor temperatures and reduced energy bills, underscoring the plank's energy efficiency.

Safety Considerations When Using the 32 Aluminum Plank

Working Safely at Heights

Safety is paramount when installing or maintaining roofing with the 32 aluminum plank. Here are some best practices:

- Use Proper Fall Protection: Always wear a harness and secure lifelines when working on steep or high roofs.

- Secure the Plank: Ensure the plank is properly fastened and supported to prevent shifting or tipping.

- Check for Slippery Surfaces: Even though the 32 aluminum plank is slip-resistant, moisture or debris can create hazards. Clean surfaces before use.

- Lift Properly: Use at least two people to move and position the 32 aluminum plank to avoid injury or dropping the plank.

Common Mistakes and How to Avoid Them

Pitfalls in Aluminum Roofing Installation

1. Improper Fastening:

Using the wrong type or spacing of fasteners can lead to panel movement or leaks. Always follow manufacturer specifications.

2. Skipping Sealant:

Overlooking the use of butyl tape or sealant at seams increases the risk of water infiltration.

3. Ignoring Expansion Gaps:

Aluminum expands and contracts with temperature changes. Leave appropriate gaps at joints to prevent buckling.

4. Walking Directly on Panels:

This can cause dents or damage. Use walk pads or boards if access is needed.

5. Neglecting Regular Inspections:

Small issues like loose screws or minor dents can become major problems if left unchecked.

User Experiences and Testimonials

What Do Real Users Say?

Testimonial 1: Roofing Contractor

"We switched to 32 aluminum planks for all our coastal projects. The installation is faster, and we haven't had a single call-back for leaks or corrosion in five years."

Testimonial 2: Homeowner

"After replacing our old shingle roof with 32 aluminum planks, our attic is noticeably cooler, and our energy bills have dropped. Plus, the roof looks fantastic."

Testimonial 3: Facility Manager

"The durability and low maintenance of the 32 aluminum plank have saved us thousands in repairs and downtime. Highly recommended for any large building."

Conclusion

The 32 aluminum plank is an exceptional choice for roofing due to its unmatched combination of strength, lightweight design, corrosion resistance, and longevity. Its ability to withstand extreme weather, reduce energy costs, and require minimal maintenance makes it a superior alternative to traditional roofing materials. Environmentally friendly, cost-effective, and adaptable to a wide range of architectural styles, the 32 aluminum plank is the ideal solution for both residential and commercial roofing projects. Whether you are a contractor seeking reliability or a homeowner looking for peace of mind, the 32 aluminum plank delivers performance and value that endures for decades.

FAQ

1. What is the weight and load capacity of a 32 aluminum plank?

A 32 aluminum plank typically weighs around 160 lbs and is rated to support up to 500 lbs, accommodating two workers and their tools safely.

2. How long does a 32 aluminum plank roof last?

With proper installation and maintenance, a 32 aluminum plank roof can last 50 years or more, outperforming most traditional roofing materials.

3. Is the 32 aluminum plank suitable for coastal or industrial environments?

Yes, its natural oxide layer provides excellent corrosion resistance, making it ideal for coastal, industrial, or high-pollution areas where other metals might degrade quickly.

4. What maintenance does a 32 aluminum plank roof require?

Routine inspections, gentle cleaning, prompt repair of minor damage, and periodic resealing of seams are recommended. Aluminum roofs are generally low maintenance compared to other materials.

5. Does a 32 aluminum plank help with energy efficiency?

Absolutely. Aluminum's high reflectivity reduces heat absorption, helping to keep buildings cooler and lowering air conditioning costs, especially in hot climates.