Content Menu

● Introduction to Ladder Clamps

● Types of Ladder Clamps

● Materials Used for Ladder Clamps

>> Steel

>> Aluminum

● Importance of Material Selection

● Safety Standards for Ladder Clamps

● Installation and Use of Ladder Clamps

● Case Studies: Successful Use of Ladder Clamps

● Challenges and Future Developments

● Conclusion

● FAQ

>> 1. What is the primary function of a ladder clamp in scaffolding?

>> 2. What materials are commonly used for ladder clamps?

>> 3. What safety standards do ladder clamps need to comply with?

>> 4. How should ladder clamps be installed?

>> 5. Why is regular inspection of ladder clamps important?

● Citations:

Scaffolding is a critical component in construction projects, providing a temporary platform for workers to access high areas safely. One of the essential safety features in scaffolding systems is the ladder clamp, which secures ladders to scaffold tubes, ensuring stability and preventing accidents. The choice of material for ladder clamps is crucial as it directly impacts the safety and durability of the scaffolding structure. In this article, we will explore the best materials for ladder clamps in scaffolding, their characteristics, and how they contribute to a safe working environment.

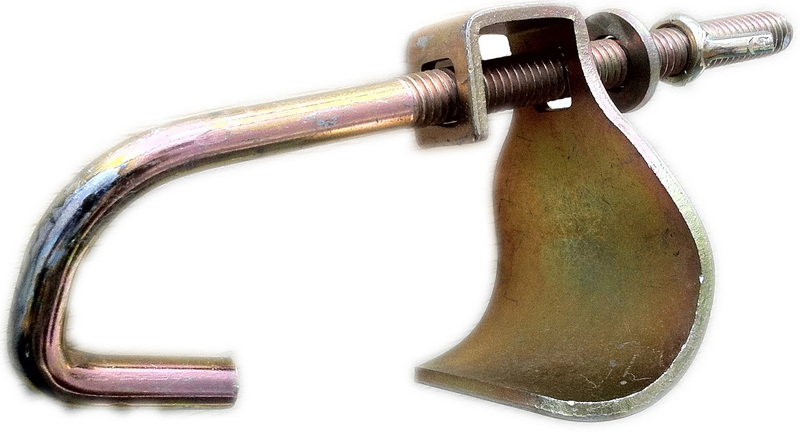

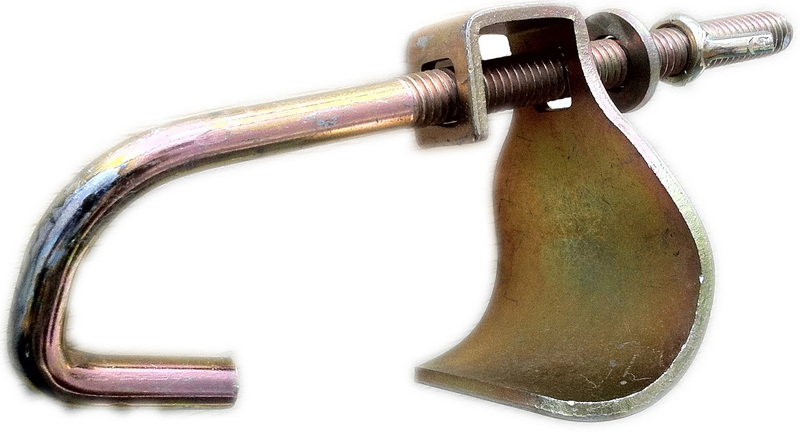

Introduction to Ladder Clamps

Ladder clamps are designed to fit onto scaffold tubes and securely hold ladders in place. They are typically made from robust materials to withstand the rigors of construction environments. The primary function of a ladder clamp is to prevent the ladder from shifting or slipping during use, thereby minimizing the risk of accidents.

Types of Ladder Clamps

There are several types of ladder clamps available, each with its unique features and advantages:

1. Pressed Steel Type: These are lightweight and cost-effective, making them suitable for general construction projects. They are often used for smaller scaffolding setups where weight is a concern.

2. Forged Type: These clamps are heavier and more robust, providing a stronger and safer connection. They are ideal for heavy-duty scaffolding applications where stability is paramount.

3. Double-Sided Ladder Clamps: These clamps offer additional security by providing two points of attachment, ensuring that ladders are firmly secured to scaffold tubes. They are versatile and can accommodate different types of ladder edges.

Materials Used for Ladder Clamps

The choice of material for ladder clamps is critical for ensuring durability and safety. The most common materials used are:

Steel

Steel is the preferred material for ladder clamps due to its strength, durability, and resistance to corrosion. Steel ladder clamps can be further categorized into:

- Zinc Plated Steel: This type offers excellent corrosion resistance, making it suitable for outdoor construction projects exposed to harsh weather conditions.

- Galvanized Steel: Galvanization provides a protective layer against rust, ensuring that the clamps remain effective even in damp environments.

Aluminum

Although less common for ladder clamps, aluminum is used in some scaffolding components due to its lightweight nature. However, it is not typically preferred for ladder clamps as it lacks the strength and durability of steel.

Importance of Material Selection

The material used for ladder clamps directly affects the safety and efficiency of scaffolding operations. Here are some factors to consider:

- Strength and Durability: The material must be strong enough to hold the weight of workers and equipment without failing.

- Corrosion Resistance: Since scaffolding is often exposed to the elements, materials with good corrosion resistance are essential to extend the lifespan of the clamps.

- Ease of Use: The material should allow for easy installation and adjustment to facilitate quick setup and dismantling of scaffolding.

Safety Standards for Ladder Clamps

Ladder clamps must comply with industry safety standards to ensure they meet the required specifications for strength and durability. Common standards include:

- BS 1139: This British Standard specifies requirements for scaffolding components, including ladder clamps, to ensure they are safe for use in construction.

- EN 74: This European Standard also covers the requirements for scaffolding couplers and fittings, including ladder clamps.

Installation and Use of Ladder Clamps

Proper installation of ladder clamps is crucial for safety. Here are some steps to follow:

1. Ensure Compatibility: Make sure the ladder clamp fits the size of your scaffold tube and ladder rungs.

2. Secure the Clamp: Use the clamp to firmly grip both the scaffold tube and the ladder rungs. Always use clamps in pairs for maximum security.

3. Regular Inspection: Regularly inspect ladder clamps for signs of wear or damage and replace them as necessary.

Case Studies: Successful Use of Ladder Clamps

Several construction projects have successfully utilized ladder clamps to ensure safe and efficient scaffolding operations:

1. High-Rise Building Construction: In a recent high-rise building project, forged steel ladder clamps were used to secure ladders to scaffolding structures. The clamps provided excellent stability, allowing workers to access high areas safely.

2. Bridge Maintenance: During a bridge maintenance project, zinc-plated steel ladder clamps were used to secure ladders to scaffolding erected over water. The corrosion-resistant properties of the clamps ensured they remained effective throughout the project.

Challenges and Future Developments

Despite the advancements in ladder clamp technology, there are still challenges to overcome:

- Material Innovation: Researchers are exploring new materials that could offer improved strength-to-weight ratios, potentially leading to lighter yet stronger ladder clamps.

- Smart Scaffolding: The integration of technology into scaffolding components, such as sensors to monitor clamp integrity, could enhance safety and efficiency in the future.

Conclusion

In conclusion, the choice of material for ladder clamps in scaffolding is critical for ensuring safety and durability. Steel, particularly zinc-plated or galvanized steel, is the preferred material due to its strength and corrosion resistance. Compliance with safety standards such as BS 1139 and EN 74 is essential to guarantee that ladder clamps meet the required specifications for construction use. As technology advances, we can expect to see more innovative features in ladder clamps that enhance safety and efficiency in scaffolding operations.

FAQ

1. What is the primary function of a ladder clamp in scaffolding?

A ladder clamp is used to secure a ladder to a scaffold tube, preventing the ladder from shifting or slipping during use, thereby enhancing worker safety.

2. What materials are commonly used for ladder clamps?

The most common material used for ladder clamps is steel, particularly zinc-plated or galvanized steel, due to its strength and corrosion resistance.

3. What safety standards do ladder clamps need to comply with?

Ladder clamps must comply with safety standards such as BS 1139 and EN 74 to ensure they meet the required specifications for strength and durability.

4. How should ladder clamps be installed?

Ladder clamps should be installed by firmly gripping both the scaffold tube and the ladder rungs. They should always be used in pairs for maximum security.

5. Why is regular inspection of ladder clamps important?

Regular inspection of ladder clamps is important to identify any signs of wear or damage. Damaged clamps should be replaced promptly to maintain safety.

Citations:

[1] https://firstfence.co.uk/ladder-clamps-steel-ladders

[2] https://www.youtube.com/watch?v=ZM6Tlh_NAnQ

[3] https://www.alibaba.com/showroom/scaffolding-clamps.html

[4] https://www.sparsteel.com/scaffolding-ladder-clamps-manufacturer.html

[5] https://www.alamy.com/stock-photo/scaffolding-clamp.html

[6] https://patents.google.com/patent/WO2018148977A1/zh

[7] https://www.wm-scaffold.com/scaffold-ladder-clamps.html

[8] https://www.shutterstock.com/video/search/ladder-on-scaffolding

[9] https://patents.google.com/patent/WO2023071385A1/zh

[10] https://patents.google.com/patent/CN113562590B/zh