Content Menu

● Introduction to Cuplock Scaffolding

● Benefits of Cuplock Scaffolding

● Components of Cuplock Scaffolding

● Assembly Procedure

● Factors Influencing Cuplock Scaffolding System Price

>> Raw Material Costs

>> Production Costs

>> Surface Treatment

● Where to Find Affordable Cuplock Scaffolding System Prices

>> Online Marketplaces

>> Local Suppliers

>> Direct Manufacturer Contact

● Tips for Purchasing Cuplock Scaffolding

● Verifying Supplier Reliability

● Additional Considerations for Cost Savings

>> Renting vs. Buying

>> Maintenance and Inspection

>> Training and Safety

● Market Trends and Future Outlook

>> Impact of Technology

>> Sustainability and Environmental Impact

● Conclusion

● FAQ

>> 1. What are the benefits of using cuplock scaffolding systems?

>> 2. How do I verify the reliability of a scaffolding supplier?

>> 3. What factors influence the price of cuplock scaffolding systems?

>> 4. Where can I find affordable cuplock scaffolding systems?

>> 5. How do I assemble a cuplock scaffolding system?

● Citations:

The cuplock scaffolding system is a popular choice for construction projects due to its modular design, ease of assembly, and cost-effectiveness. Finding the most affordable price for this system requires understanding the market, suppliers, and factors influencing costs. This article will guide you through the process of locating the best deals on cuplock scaffolding systems.

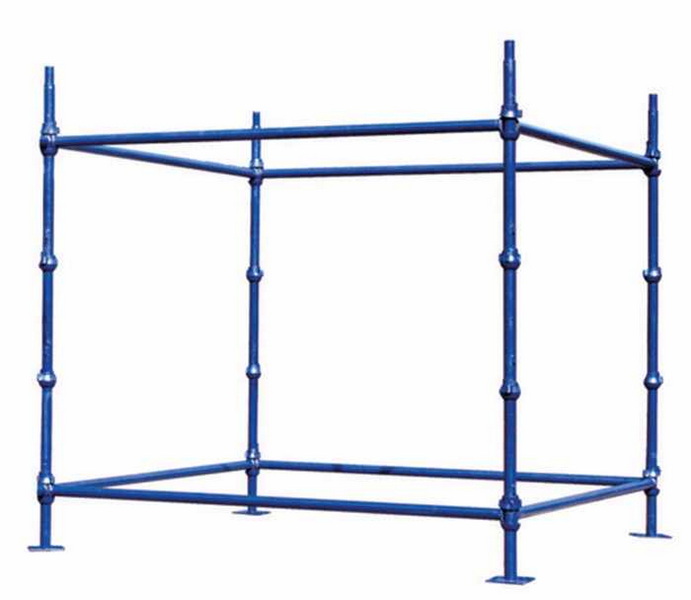

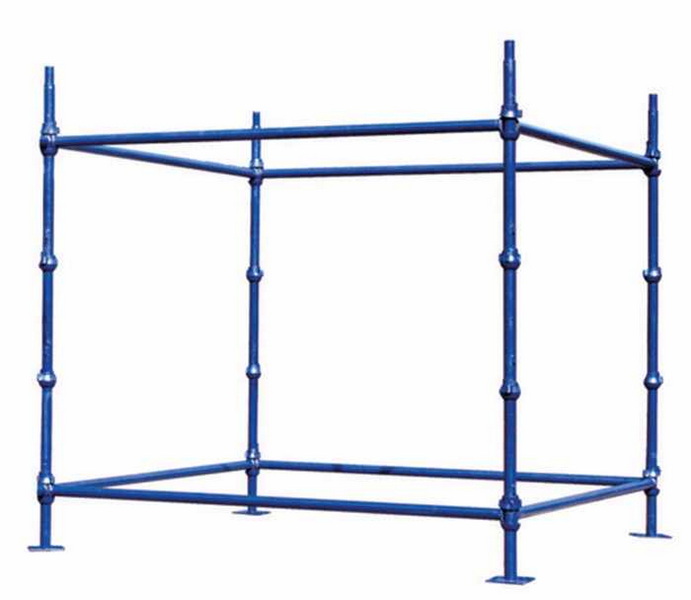

Introduction to Cuplock Scaffolding

Cuplock scaffolding is a type of modular scaffolding system widely used in construction for supporting workers and materials at height. It consists of vertical standards with cups welded at regular intervals and horizontal ledgers that connect to these standards using a locking mechanism. This system is known for its speed and efficiency in assembly and dismantling, enhancing safety and stability while reducing labor costs and project timelines.

Benefits of Cuplock Scaffolding

- Speed and Efficiency: The modular design allows for rapid assembly and dismantling, reducing labor costs and project timelines.

- Safety and Stability: The secure locking mechanism provides enhanced stability and load-bearing capacity, reducing the risk of accidents.

- Cost-effectiveness: The streamlined assembly process and reusable components offer cost savings over time compared to traditional scaffolding methods.

Components of Cuplock Scaffolding

The cuplock scaffolding system includes several key components:

- Vertical Standards: Made from high-grade steel tubes with fixed lower cups at 0.5m intervals.

- Ledgers and Transoms: Horizontal components that connect to the vertical standards.

- Base and Head Plate: Essential for stabilizing the scaffold.

- Universal Jack: Used for leveling the scaffold.

- Bracing: Provides additional stability to the structure.

Assembly Procedure

The assembly of cuplock scaffolding involves several steps:

1. Base Setup: Establish a stable base using base plates and jacks.

2. Vertical Standards: Place vertical standards and connect them with ledgers.

3. Locking Mechanism: Use the cuplock mechanism to secure ledgers and transoms.

4. Bracing: Add diagonal bracing for stability.

Factors Influencing Cuplock Scaffolding System Price

The price of cuplock scaffolding systems is influenced by several factors:

- Raw Material Costs: The cost of steel and other materials used in manufacturing.

- Production Costs: Efficiency in manufacturing processes can reduce costs.

- Surface Treatment: Different finishes like galvanization or powder coating affect the price.

Raw Material Costs

Raw material costs, particularly steel, significantly impact the overall price. Manufacturers with their own steel mills can offer more competitive pricing due to reduced procurement costs.

Production Costs

Efficient production processes, such as automated manufacturing, can lower costs by increasing output and reducing labor expenses.

Surface Treatment

The type of surface treatment, such as hot-dip galvanization or powder coating, adds to the cost but enhances durability and resistance to corrosion.

Where to Find Affordable Cuplock Scaffolding System Prices

To find the most affordable cuplock scaffolding system prices, consider the following options:

Online Marketplaces

- Alibaba: Offers a wide range of cuplock scaffolding products with competitive pricing, often with trade assurance for buyer protection.

- Made-in-China: Provides listings from trusted manufacturers and suppliers, allowing for easy comparison of prices and specifications.

- TradeIndia: Features various suppliers with detailed product descriptions and price trends.

Local Suppliers

- IndiaMART: Lists local Indian suppliers with detailed product information and contact details.

- Local Construction Supply Stores: Visiting local stores can provide insights into available stock and prices.

Direct Manufacturer Contact

- Wellmade: Known for its efficient manufacturing processes and competitive pricing due to in-house raw material sourcing and production facilities.

Tips for Purchasing Cuplock Scaffolding

When purchasing cuplock scaffolding, consider the following tips:

- Verify Supplier Reliability: Check for certifications, customer reviews, and product specifications.

- Compare Prices: Use online platforms to compare prices from different suppliers.

- Customization Options: Ensure the supplier can meet your specific project requirements.

Verifying Supplier Reliability

To ensure you're dealing with a reliable supplier, conduct thorough research, request certifications, and communicate regularly to understand their production processes and quality standards.

Additional Considerations for Cost Savings

Renting vs. Buying

- Renting: Ideal for short-term projects or when budget is limited. It eliminates maintenance costs and allows for flexibility in project timelines.

- Buying: Suitable for long-term projects or frequent use. Although the initial cost is higher, it provides long-term cost savings and control over equipment condition.

Maintenance and Inspection

Regular maintenance and inspection are crucial to extend the lifespan of cuplock scaffolding systems. This includes checking for damage, ensuring proper storage, and applying protective coatings to prevent corrosion.

Training and Safety

Investing in proper training for scaffolding assembly and use can significantly reduce accidents and improve project efficiency. Ensure that all workers are aware of safety protocols and best practices.

Market Trends and Future Outlook

The demand for cuplock scaffolding systems is expected to grow due to increasing construction activities globally. Advances in technology and manufacturing processes are likely to further enhance efficiency and reduce costs.

Impact of Technology

Technological advancements, such as automated manufacturing lines and advanced materials, are expected to improve production efficiency and reduce costs. Additionally, digital platforms will continue to play a crucial role in connecting buyers with suppliers worldwide.

Sustainability and Environmental Impact

As the construction industry moves towards sustainability, there is a growing focus on environmentally friendly scaffolding systems. This includes using recycled materials and designing systems for easy disassembly and reuse.

Conclusion

Finding the most affordable cuplock scaffolding system price involves understanding the market, comparing prices across different suppliers, and considering factors that influence costs. By leveraging online marketplaces and contacting local suppliers, you can secure the best deals for your construction projects. Additionally, considering long-term cost savings through proper maintenance and training can further enhance the value of your investment.

FAQ

1. What are the benefits of using cuplock scaffolding systems?

Cuplock scaffolding systems offer speed and efficiency in assembly, enhanced safety and stability, and cost-effectiveness due to reusable components.

2. How do I verify the reliability of a scaffolding supplier?

To verify a supplier's reliability, conduct thorough research, check customer reviews, request certifications, and maintain regular communication to understand their production processes and quality standards.

3. What factors influence the price of cuplock scaffolding systems?

The price is influenced by raw material costs, production efficiency, and surface treatment costs. Manufacturers with in-house steel mills and efficient production processes can offer more competitive pricing.

4. Where can I find affordable cuplock scaffolding systems?

Affordable cuplock scaffolding systems can be found on online marketplaces like Alibaba and Made-in-China, as well as through local suppliers listed on platforms like IndiaMART.

5. How do I assemble a cuplock scaffolding system?

Assembly involves setting up a stable base, placing vertical standards, connecting ledgers using the cuplock mechanism, and adding bracing for stability. Refer to assembly videos for detailed instructions.

Citations:

[1] https://www.made-in-china.com/products-search/hot-china-products/Cuplock_Scaffold_Price.html

[2] https://www.youtube.com/watch?v=ojYR6MRAoEI

[3] https://www.tradeindia.com/manufacturers/cuplock-scaffolding-system.html

[4] https://www.alibaba.com/showroom/cuplock-scaffolding-prices.html

[5] https://www.youtube.com/watch?v=QSKy3RkmKs8

[6] https://dir.indiamart.com/impcat/cuplock-scaffolding.html

[7] https://www.wm-scaffold.com/cup-lock-scaffold.html

[8] https://www.youtube.com/watch?v=2FbwLFj1aFY

[9] https://www.tradeindia.com/manufacturers/cuplock-scaffolding.html