Content Menu

● Introduction to Tube and Clamp Scaffolding

● Components of Tube and Clamp Scaffolding

● Advantages of Tube and Clamp Scaffolding

>> High Load Capacity

>> Flexibility and Customization

>> Easy Assembly and Disassembly

>> Cost-Effectiveness

>> Safety Features

● Applications of Tube and Clamp Scaffolding

● Case Study: High-Rise Building Construction

● Safety Considerations

● Maintenance and Storage

● Environmental Impact

● Conclusion

● FAQ

>> 1. What are the primary components of tube and clamp scaffolding?

>> 2. What are the advantages of using tube and clamp scaffolding?

>> 3. How does tube and clamp scaffolding ensure safety?

>> 4. What are the common applications of tube and clamp scaffolding?

>>> 5. How can I ensure the scaffolding meets safety standards?

● Citations:

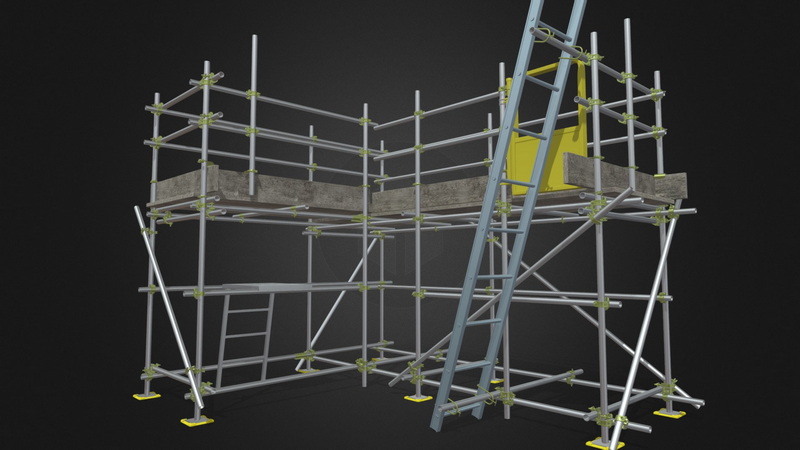

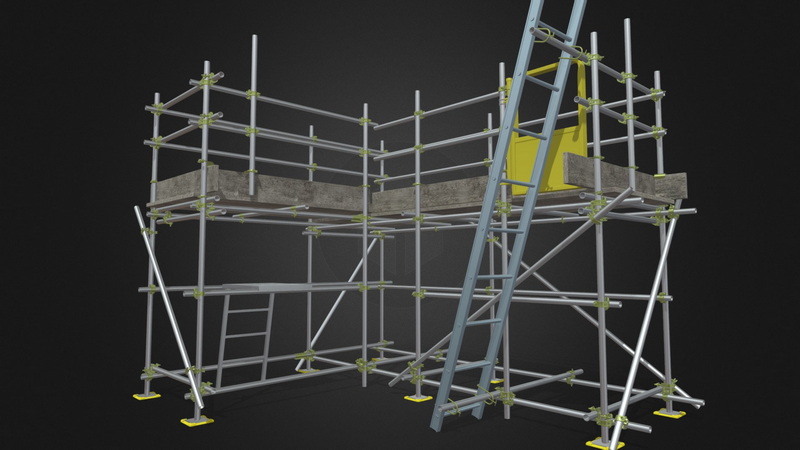

Tube and clamp scaffolding is a versatile, reliable, and widely used system in the construction industry. It offers numerous benefits, including high strength, flexibility, and ease of assembly, making it an ideal choice for various projects. In this article, we will explore the advantages, components, and applications of tube and clamp scaffolding, along with practical tips for its use.

Introduction to Tube and Clamp Scaffolding

Tube and clamp scaffolding consists of steel or aluminum tubes connected by clamps, which provide a stable platform for workers. This system is highly adaptable and can be configured to suit different construction needs, from simple repairs to complex high-rise projects.

Components of Tube and Clamp Scaffolding

1. Tubes: These are the primary structural elements, available in various lengths and materials such as steel or aluminum. Steel tubes are preferred for their strength and durability, while aluminum tubes are lighter and more suitable for projects requiring frequent relocation.

2. Clamps: These are metal connectors used to secure the tubes together. There are two main types:

- Right-Angle Clamps: Used to connect tubes at right angles, forming corners.

- Swivel Clamps: Allow tubes to be connected at any angle, providing flexibility in scaffolding design.

3. Base Plates: These are placed on the ground to distribute the weight of the scaffolding evenly and prevent it from tipping over.

4. Boards: These are the platform materials used to create a safe working surface for workers.

5. Guardrails and Toeboards: These are essential safety components that prevent falls and ensure a secure working environment.

Advantages of Tube and Clamp Scaffolding

High Load Capacity

Tube and clamp scaffolding is capable of supporting heavy loads, making it suitable for large-scale construction projects. The load-bearing capacity of a single tube can range from 15kN to 35kN, depending on the design specifications.

Flexibility and Customization

The scaffolding can be easily adjusted to different heights and configurations, allowing it to fit complex building structures. This flexibility is crucial for projects with unique architectural designs.

Easy Assembly and Disassembly

The system is simple to assemble and disassemble, which saves time on construction sites. This ease of setup also reduces labor costs and enhances project efficiency.

Cost-Effectiveness

Tube and clamp scaffolding is relatively economical compared to other scaffolding systems. It requires minimal processing and has a low one-time investment cost.

Safety Features

The scaffolding provides a stable and secure platform for workers, ensuring safety during operations. Properly installed clamps and tubes ensure that the structure can withstand various environmental conditions.

Applications of Tube and Clamp Scaffolding

Tube and clamp scaffolding is widely used in various industries, including:

- Construction: Ideal for building, renovation, and repair projects.

- Industrial Maintenance: Used for tasks requiring access to high areas, such as painting or cleaning.

- Event Setup: Often used for setting up stages or temporary structures for events.

Case Study: High-Rise Building Construction

In a recent high-rise construction project, tube and clamp scaffolding was used to provide access to exterior walls for glazing and facade installation. The scaffolding's flexibility allowed it to be adjusted to fit the building's complex design, ensuring efficient completion of the project.

Safety Considerations

When using tube and clamp scaffolding, it is essential to follow safety guidelines to prevent accidents:

1. Proper Assembly: Ensure all components are securely connected and the structure is level.

2. Regular Inspections: Conduct regular checks for any damage or wear on the scaffolding.

3. Load Capacity: Never exceed the maximum load capacity of the scaffolding.

4. Weather Conditions: Ensure the scaffolding is secured against wind and other environmental factors.

5. Training: Ensure all workers using the scaffolding are properly trained.

Maintenance and Storage

Proper maintenance and storage of tube and clamp scaffolding components are crucial for extending their lifespan:

- Cleaning: Regularly clean tubes and clamps to prevent corrosion.

- Storage: Store components in a dry area to prevent rust.

Environmental Impact

Tube and clamp scaffolding is generally environmentally friendly due to its reusability and minimal waste generation. However, it is important to ensure that all materials are disposed of responsibly at the end of their lifecycle.

Conclusion

Tube and clamp scaffolding offers a robust, flexible, and cost-effective solution for construction projects. Its ability to support heavy loads, adapt to complex structures, and be easily assembled makes it a preferred choice in the industry. By understanding its components, advantages, and safety considerations, project managers can effectively utilize tube and clamp scaffolding to enhance efficiency and safety on site.

FAQ

1. What are the primary components of tube and clamp scaffolding?

Tube and clamp scaffolding primarily consists of tubes (made from steel or aluminum), clamps (right-angle and swivel), base plates, boards for the platform, and guardrails for safety.

2. What are the advantages of using tube and clamp scaffolding?

The advantages include high load capacity, flexibility in design, ease of assembly and disassembly, cost-effectiveness, and safety features.

3. How does tube and clamp scaffolding ensure safety?

Safety is ensured through proper assembly, regular inspections, adherence to load capacity limits, and the use of guardrails and toeboards. Additionally, the scaffolding provides a stable platform for workers.

4. What are the common applications of tube and clamp scaffolding?

Common applications include construction, industrial maintenance, and event setup.

5. How can I ensure the scaffolding meets safety standards?

Ensure compliance with industry standards and local regulations. Regularly inspect the scaffolding for any damage and maintain proper assembly practices.

Citations:

[1] https://safetyeducations.com/tube-and-coupler-scaffolds/

[2] https://www.youtube.com/watch?v=iUqDWjr6uok

[3] https://www.alibaba.com/showroom/tube-and-clamp-scaffold.html

[4] https://www.adtoscaffold.com/new/pros_and_cons_of_tube_and_clamp_scaffolding.html

[5] https://www.youtube.com/watch?v=ZM6Tlh_NAnQ

[6] https://patents.google.com/patent/WO2019144468A1/zh

[7] https://www.grinsulating.com/top-benefits-tube-and-clamp-scaffold/

[8] https://www.shutterstock.com/video/search/scaffolding-clamp