Content Menu

● Introduction to Scaffolding Couplers

● Types of Scaffolding Couplers

● The Role of Scaffolding Single Couplers

● Applications of Scaffolding Single Couplers

● Safety Considerations with Scaffolding Single Couplers

● Benefits of Using Scaffolding Single Couplers

● Design and Manufacturing of Scaffolding Single Couplers

● Materials Used

● Regulations and Standards for Scaffolding Couplers

● Compliance with Regulations

● Innovations in Scaffolding Couplers

● Future Developments

● Case Studies: Successful Use of Scaffolding Single Couplers

● Example Projects

● Conclusion

● FAQ

>> 1. What is a scaffolding single coupler used for?

>> 2. How do scaffolding single couplers contribute to safety?

>> 3. What are the benefits of using scaffolding single couplers?

>> 4. How should scaffolding single couplers be maintained?

>> 5. Can scaffolding single couplers be used in complex building shapes?

● Citations:

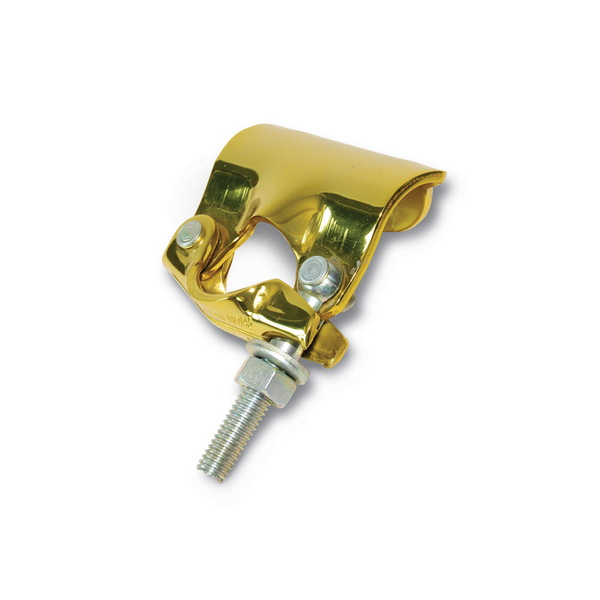

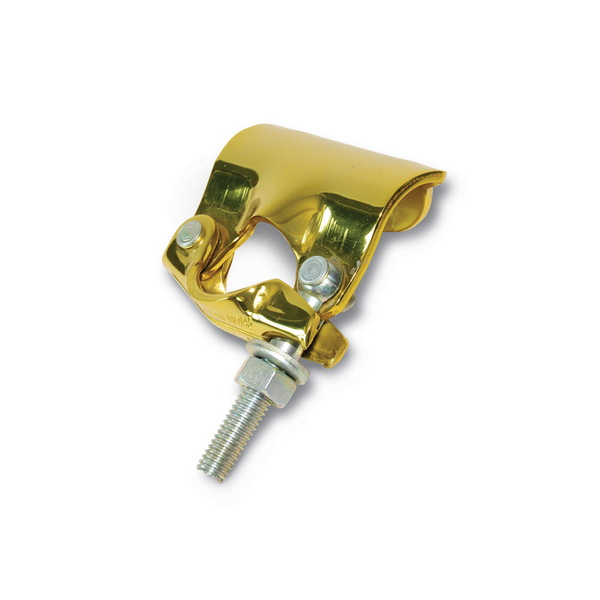

Scaffolding single couplers are a crucial component in the construction industry, playing a vital role in ensuring the safety and stability of scaffolding structures. These couplers are designed to connect horizontal putlogs to ledgers or standards, providing a secure platform for workers to stand on during construction activities. In this article, we will delve into the importance of scaffolding single couplers, their applications, types, and how they contribute to efficient and safe construction practices.

Introduction to Scaffolding Couplers

Scaffolding couplers are essential hardware components used in construction to connect scaffolding tubes, creating a strong and stable framework for workers and materials at various heights. They come in different types, each serving specific purposes such as connecting tubes end-to-end, at right angles, or at different angles to accommodate complex building shapes.

Types of Scaffolding Couplers

1. Sleeve Couplers: These connect tubes end-to-end, allowing for continuous length adjustments.

2. Right-Angle Couplers: Used to connect tubes perpendicularly, forming corners or T-junctions.

3. Swivel Couplers: Enable tubes to be connected at various angles, providing flexibility in scaffolding design.

4. Board Retaining Couplers: Secure scaffold boards in place, ensuring a safe working surface.

5. Anchor Couplers: Attach scaffolding to buildings or structures, preventing movement during windy conditions.

The Role of Scaffolding Single Couplers

Scaffolding single couplers, also known as putlog couplers, are specifically designed to attach horizontal putlogs to ledgers or standards. This connection supports the platform where workers stand, ensuring it remains safe and steady during construction activities.

Applications of Scaffolding Single Couplers

- Supporting Structures: Single couplers help build scaffolding frames that hold workers, tools, and materials at heights.

- Creating Platforms: They connect horizontal parts like ledgers and putlogs to vertical poles, forming stable platforms.

- Shaping Complex Structures: Although single couplers are primarily used for straight connections, they contribute to the overall flexibility of scaffolding systems by allowing for adjustments in platform positioning.

Safety Considerations with Scaffolding Single Couplers

Safety is paramount when using scaffolding single couplers. Proper installation and maintenance are crucial to prevent accidents. Here are some safety tips:

- Correct Installation: Ensure that couplers are securely tightened and properly aligned.

- Regular Inspections: Check for any damage or wear on couplers and replace them if necessary.

- Load Capacity: Do not exceed the recommended load capacity of the scaffolding structure.

Benefits of Using Scaffolding Single Couplers

1. Stability and Safety: Single couplers provide a stable platform for workers, reducing the risk of accidents.

2. Efficiency: They allow for quick assembly and disassembly of scaffolding, saving time and resources.

3. Flexibility: Although primarily used for straight connections, they contribute to the overall adaptability of scaffolding systems.

Design and Manufacturing of Scaffolding Single Couplers

Scaffolding single couplers are typically made from durable materials such as steel or aluminum, ensuring they can withstand heavy loads and harsh environmental conditions. The design of these couplers involves precise engineering to ensure a secure fit between the putlog and the ledger or standard, preventing any movement or slippage.

Materials Used

- Steel: Known for its strength and durability, steel is commonly used for scaffolding couplers.

- Aluminum: Offers a lighter alternative while maintaining strength, ideal for projects where weight is a concern.

Regulations and Standards for Scaffolding Couplers

Regulatory bodies such as OSHA in the United States and the European Union's EN standards provide guidelines for the use and maintenance of scaffolding couplers. These regulations ensure that couplers meet specific safety and performance standards, protecting workers and preventing accidents.

Compliance with Regulations

- Regular Inspections: Mandatory to ensure couplers are in good condition.

- Training: Workers must be trained on proper installation and use of scaffolding couplers.

Innovations in Scaffolding Couplers

Recent innovations in scaffolding couplers include the development of advanced materials and designs that improve durability and ease of use. For example, some couplers now feature quick-release mechanisms, allowing for faster assembly and disassembly.

Future Developments

- Smart Couplers: Incorporating technology to monitor load capacity and detect potential issues.

- Sustainable Materials: Exploring eco-friendly materials for coupler production.

Case Studies: Successful Use of Scaffolding Single Couplers

Several construction projects have successfully utilized scaffolding single couplers to achieve safe and efficient scaffolding systems. For instance, in the renovation of historic buildings, single couplers have been used to create stable platforms while preserving the integrity of the structure.

Example Projects

- Historic Building Renovation: Used to support delicate restoration work.

- High-Rise Construction: Essential for building stable platforms at great heights.

Conclusion

Scaffolding single couplers are essential components in construction, offering stability, safety, and efficiency in scaffolding systems. Their ability to support platforms and connect horizontal elements securely makes them indispensable for building and maintaining structures at heights. Understanding the proper use and maintenance of these couplers is crucial for ensuring safe and successful construction projects.

FAQ

1. What is a scaffolding single coupler used for?

A scaffolding single coupler, or putlog coupler, is used to attach horizontal putlogs to ledgers or standards in scaffolding, supporting the platform where workers stand.

2. How do scaffolding single couplers contribute to safety?

Scaffolding single couplers contribute to safety by providing a stable platform for workers, reducing the risk of accidents. Proper installation and regular inspections are crucial for maintaining safety.

3. What are the benefits of using scaffolding single couplers?

The benefits include stability and safety for workers, efficiency in assembly and disassembly, and flexibility in scaffolding design.

4. How should scaffolding single couplers be maintained?

Regular inspections should be conducted to check for damage or wear. Couplers should be replaced if damaged, and they should always be properly tightened during installation.

5. Can scaffolding single couplers be used in complex building shapes?

While single couplers are primarily used for straight connections, they contribute to the overall flexibility of scaffolding systems by allowing adjustments in platform positioning. However, for complex shapes, other types of couplers like swivel couplers are more suitable.

Citations:

[1] https://scaffoldtype.com/scaffolding-coupler/

[2] https://www.youtube.com/watch?v=D3U9C58KEpk

[3] https://patents.google.com/patent/WO2003091512A1/zh

[4] https://apacsafety.com/the-ultimate-guide-of-scaffolding-couplers/

[5] https://www.youtube.com/watch?v=xikbzjq-f3I

[6] https://www.bbc.com/learningenglish/chinese/features/q-and-a/ep-200318

[7] https://www.youtube.com/watch?v=a5VG7k_boDs

[8] https://www.youtube.com/watch?v=NJd7ThUKaFA