Content Menu

● What Is a Scaffolding Climbing Frame?

● Key Benefits of Using a Scaffolding Climbing Frame for High-Rise Projects

>> 1. Enhanced Safety at Height

>> 2. Increased Efficiency and Productivity

>> 3. Reduced Project Costs

>> 4. Adaptability to Complex Structures

>> 5. Weather and Environmental Protection

● How Does a Scaffolding Climbing Frame Work?

>> Crane-Dependent vs. Self-Climbing Systems

>> Integration with Formwork

● Safety Features and Best Practices for Scaffolding Climbing Frames

>> Personal Protective Equipment (PPE)

>> Platform Safety

>> Assembly and Maintenance

>> Electrical and Environmental Safety

● Expanding the Benefits: Digital Integration and Project Management

>> Digital Planning and BIM Integration

>> Sustainability and Lifecycle Management

● Comparing Scaffolding Climbing Frames with Other Scaffolding Systems

● Real-World Applications of Scaffolding Climbing Frames

● Innovations in Scaffolding Climbing Frame Technology

● Maintenance and Inspection Best Practices

● Environmental and Social Impact

● Conclusion

● FAQ

>> 1. How does a scaffolding climbing frame improve safety on high-rise projects?

>> 2. Is a scaffolding climbing frame more efficient than traditional scaffolding for tall buildings?

>> 3. Can a scaffolding climbing frame be used for buildings with complex shapes?

>> 4. What are the main safety practices when using a scaffolding climbing frame?

>> 5. Are there different types of scaffolding climbing frames?

High-rise construction is one of the most demanding sectors in the building industry, pushing the boundaries of engineering, safety, and efficiency. As buildings soar higher, the need for advanced access solutions becomes paramount. The scaffolding climbing frame has emerged as a game-changer for high-rise projects, offering unmatched safety, speed, and versatility.

What Is a Scaffolding Climbing Frame?

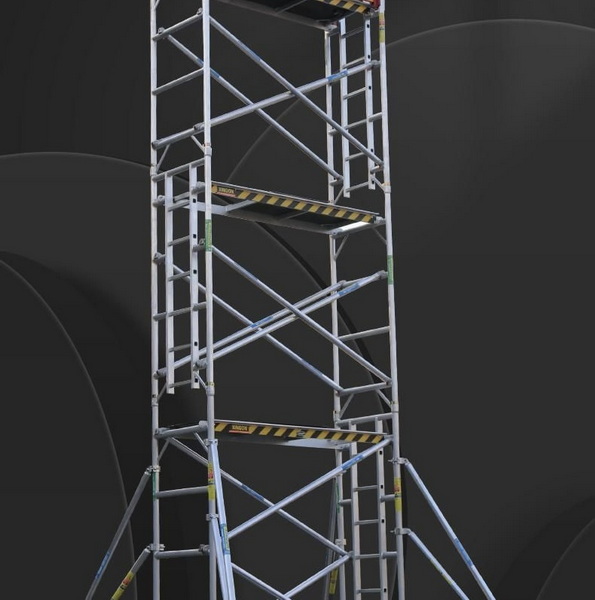

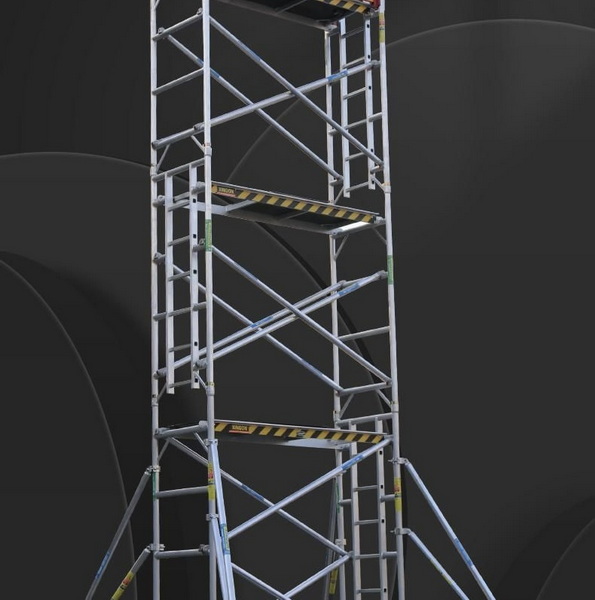

A scaffolding climbing frame is a modular, engineered platform system designed to ascend alongside a building as construction progresses. Unlike traditional scaffolds, which are assembled from the ground up and extended manually, climbing frames are either crane-lifted or self-climbing, attached to the structure, and can be raised in sync with the building's vertical growth. These systems are engineered for high-rise environments, supporting heavy loads, and integrating with formwork and other construction operations.

Key Benefits of Using a Scaffolding Climbing Frame for High-Rise Projects

1. Enhanced Safety at Height

Safety is the top concern in high-rise construction. Scaffolding climbing frames are designed with robust guardrails, wide working platforms, and protective netting, significantly reducing the risk of falls and dropped objects.

- Stable Platforms: Climbing frames offer a stable, barrier-free workspace, even at extreme heights.

- Integrated Safety Features: Guardrails, toe boards, and debris netting are standard, protecting both workers and the public below.

- Reduced Manual Handling: Since the frame climbs with the structure, less manual assembly at height is needed, lowering accident risk.

2. Increased Efficiency and Productivity

Time is money in high-rise construction. Scaffolding climbing frames streamline workflows by providing continuous, safe access as the building rises.

- Faster Construction Cycles: The frame climbs as the structure grows, eliminating the need to dismantle and re-erect scaffolding at each floor.

- Wider Work Areas: Large, uninterrupted platforms allow multiple trades to work simultaneously.

- Integrated Formwork Support: Many systems combine climbing scaffolding and formwork, enabling rapid concrete pours and follow-up work.

3. Reduced Project Costs

By promoting faster and safer construction, scaffolding climbing frames can lead to significant cost savings.

- Lower Labor Costs: Less time spent on scaffold assembly, dismantling, and repositioning.

- Reduced Crane Time: Self-climbing systems require minimal crane use, freeing cranes for other tasks.

- Decreased Material Loss: Integrated safety nets and platforms minimize dropped tools and materials.

4. Adaptability to Complex Structures

Modern high-rise buildings often feature complex geometries. Scaffolding climbing frames are highly adaptable, with modular components that can be configured to fit curved, angled, or irregular facades.

- Customizable Layouts: Platforms and supports can be adjusted to match the building's shape.

- Versatile Applications: Suitable for rebar work, formwork installation, concrete pouring, and finishing tasks.

5. Weather and Environmental Protection

High-rise projects are exposed to wind, rain, and other environmental hazards. Climbing frames can incorporate protective screens or enclosures, shielding workers and materials from the elements and improving productivity in adverse weather.

- Wind Shields and Enclosures: These can be added to the scaffolding climbing frame to minimize wind impact, protect against rain, and create a safer, more comfortable environment for workers.

- Dust and Debris Control: Enclosed climbing frames help contain dust and debris, reducing the risk of environmental contamination and improving site cleanliness.

How Does a Scaffolding Climbing Frame Work?

Crane-Dependent vs. Self-Climbing Systems

- Crane-Dependent Climbing Frames: Lifted by tower cranes and anchored to the building, these platforms are repositioned as each floor is completed.

- Self-Climbing (Hydraulic/Electric) Frames: Equipped with mechanical jacks or hydraulic systems, these platforms ascend automatically, independent of cranes, by climbing up rails or anchors fixed to the structure.

Integration with Formwork

Many climbing frames are paired with climbing formwork, allowing for seamless concrete placement and finishing. The frame and formwork move together, creating a synchronized workflow.

Safety Features and Best Practices for Scaffolding Climbing Frames

Personal Protective Equipment (PPE)

- Harnesses and Lanyards: Mandatory for all workers on climbing frames.

- Non-Slip Footwear and Gloves: Essential for grip and stability.

- Tool Tethering: Prevents dropped objects from endangering workers below.

Platform Safety

- Guardrails and Toe Boards: Prevent falls and contain tools/materials.

- Debris Netting: Catches falling objects and provides wind protection.

- Wide Platforms: Allow safe movement and material handling.

Assembly and Maintenance

- Competent Supervision: Only trained personnel should assemble, operate, or maintain climbing frames.

- Regular Inspections: Daily checks for structural integrity, anchor security, and platform condition.

- Adherence to Manufacturer Guidelines: Follow all assembly, operation, and maintenance instructions.

Electrical and Environmental Safety

- Minimum Clearance from Power Lines: Maintain at least 10 feet from electrical hazards.

- Stable Ground and Barriers: Ensure proper base setup and protection from vehicular impact.

Expanding the Benefits: Digital Integration and Project Management

Digital Planning and BIM Integration

The use of Building Information Modeling (BIM) and digital project management tools is transforming how scaffolding climbing frames are planned and executed on high-rise sites.

- 3D Visualization: Project managers can model the scaffolding climbing frame in relation to the building, identifying potential clashes and optimizing logistics.

- Scheduling and Sequencing: Digital tools help coordinate the climbing frame's movement with other trades, minimizing downtime and maximizing efficiency.

- Safety Audits: Digital checklists and inspection logs ensure compliance and streamline reporting.

Sustainability and Lifecycle Management

Scaffolding climbing frames are designed for repeated use across multiple projects, supporting sustainable construction practices.

- Durable Materials: High-strength steel and corrosion-resistant coatings extend service life.

- Reduced Waste: Modular components are reused, minimizing material waste.

- Efficient Logistics: Digital tracking of frame components ensures they are maintained, inspected, and redeployed efficiently.

Comparing Scaffolding Climbing Frames with Other Scaffolding Systems

| Feature | Scaffolding Climbing Frame | Traditional Frame Scaffolding | Suspended Scaffolding |

| Maximum Height | 100+ stories | 4–6 stories (practical) | Unlimited (by cable) |

| Platform Stability | Very High | Moderate | Moderate |

| Efficiency on High-Rises | Excellent | Poor | Good |

| Crane Dependency | Optional (self-climbing) | Required for tall builds | No |

| Safety Features | Advanced | Basic | Moderate |

| Adaptability to Building Shape | High | Moderate | Low |

| Labor Requirement | Low | High | Moderate |

Real-World Applications of Scaffolding Climbing Frames

- Skyscraper Construction: Used for core wall construction, facade work, and finishing on towers worldwide.

- Bridge Piers and Tall Structures: Essential for safe, efficient access to tall, narrow structures.

- Complex Architectural Projects: Adaptable to curved, sloped, or irregular building designs.

- Industrial Plants: Used for maintenance and upgrades on tall tanks, silos, and chimneys.

Innovations in Scaffolding Climbing Frame Technology

- Digital Integration: Modern climbing frames can be modeled in BIM (Building Information Modeling) for precise planning and clash detection.

- Smart Sensors: Some systems include load sensors and real-time monitoring for enhanced safety.

- Modular Upgrades: Platforms can be expanded or reconfigured mid-project to adapt to changing site needs.

- Remote Monitoring: Advanced climbing frames may include IoT-enabled sensors for remote inspection and real-time alerts about load, wind, or movement.

- Green Coatings: Use of environmentally friendly paints and galvanization for improved sustainability and reduced maintenance.

Maintenance and Inspection Best Practices

To maximize safety and performance, scaffolding climbing frames must be rigorously maintained:

- Routine Inspections: Daily and weekly checks for wear, corrosion, and secure anchorage.

- Component Tracking: Use of barcodes or RFID tags to track frame parts and maintenance history.

- Scheduled Overhauls: Periodic disassembly and thorough inspection between projects.

- Documentation: Maintain detailed logs of inspections, repairs, and modifications for compliance and traceability.

Environmental and Social Impact

The use of scaffolding climbing frames in high-rise projects not only improves construction outcomes but also enhances worker welfare and urban safety:

- Reduced Street-Level Disruption: Climbing frames minimize the need for ground-based scaffolding, keeping sidewalks and roads clearer.

- Noise and Dust Control: Enclosed climbing frames help contain noise and debris, reducing the impact on neighboring properties.

- Worker Morale: Safer, more comfortable workspaces at height contribute to higher morale and retention among skilled trades.

Conclusion

The scaffolding climbing frame is an essential tool for high-rise construction, offering unparalleled safety, efficiency, and adaptability. Its ability to ascend with the building, provide stable and wide work platforms, and integrate advanced safety features makes it the preferred choice for modern skyscraper projects. By reducing labor, project duration, and costs while maximizing safety and productivity, climbing frames are transforming how the world builds upward. For any high-rise project, investing in a quality scaffolding climbing frame system is a decision that pays dividends in safety, speed, and success.

FAQ

1. How does a scaffolding climbing frame improve safety on high-rise projects?

A scaffolding climbing frame provides stable, wide platforms with integrated guardrails, toe boards, and debris netting, significantly reducing fall and dropped-object risks. Its engineered design and secure attachment to the structure ensure safety even at extreme heights.

2. Is a scaffolding climbing frame more efficient than traditional scaffolding for tall buildings?

Yes. Climbing frames move with the building as it rises, eliminating the need for repeated scaffold assembly and dismantling. This speeds up construction cycles, reduces labor, and allows multiple trades to work simultaneously.

3. Can a scaffolding climbing frame be used for buildings with complex shapes?

Absolutely. Modern climbing frames are modular and can be configured to match curved, angled, or irregular facades, making them suitable for even the most architecturally challenging high-rise projects.

4. What are the main safety practices when using a scaffolding climbing frame?

Key practices include using PPE (harnesses, non-slip footwear), tool tethering, conducting daily inspections, maintaining proper clearance from power lines, and ensuring only trained personnel assemble and operate the system.

5. Are there different types of scaffolding climbing frames?

Yes. There are crane-dependent climbing frames, which are lifted by tower cranes, and self-climbing frames, which use hydraulic or electric systems to ascend independently. The choice depends on project needs, crane availability, and building design.