Content Menu

● Introduction to Ringlock Scaffolding Accessories

● Key Features of Ringlock Scaffolding Accessories

● Types of Ringlock Scaffolding Accessories

● Suitability for Heavy-Duty Applications

● Load Capacity and Structural Stability

● Load Capacity Test Results

● Safety Considerations

● Customization and Adaptability

● Environmental Considerations

● Cost Efficiency and Logistics

● Comparison with Other Scaffolding Accessories

● Case Studies: Heavy-Duty Applications

● Maintenance and Durability

● Ensuring Safety During Assembly and Disassembly

● Conclusion

● FAQ

>> 1. What are the primary types of ringlock scaffolding accessories?

>> 2. How do ringlock scaffolding accessories enhance worker safety?

>> 3. What types of projects are ringlock scaffolding accessories suitable for?

>> 4. How do the materials used in ringlock scaffolding accessories impact their durability?

>> 5. What are the benefits of using ringlock scaffolding accessories in terms of cost efficiency?

● Citations:

Ringlock scaffolding accessories are designed to enhance the functionality and safety of ringlock scaffolding systems, which are widely used in construction and industrial projects. These accessories play a crucial role in ensuring that the scaffolding system can support heavy loads and provide a stable working platform for workers. In this article, we will explore whether ringlock scaffolding accessories can be used for heavy-duty applications and discuss their features, benefits, and usage.

Introduction to Ringlock Scaffolding Accessories

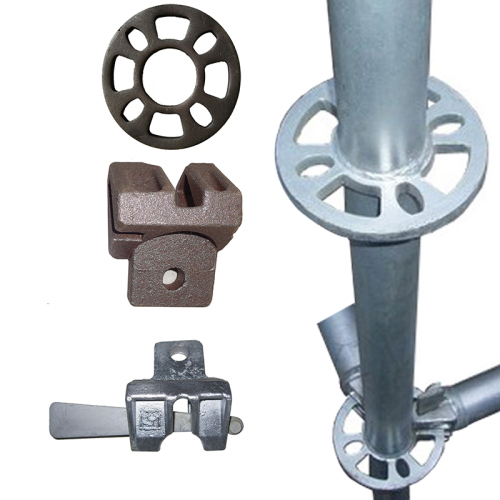

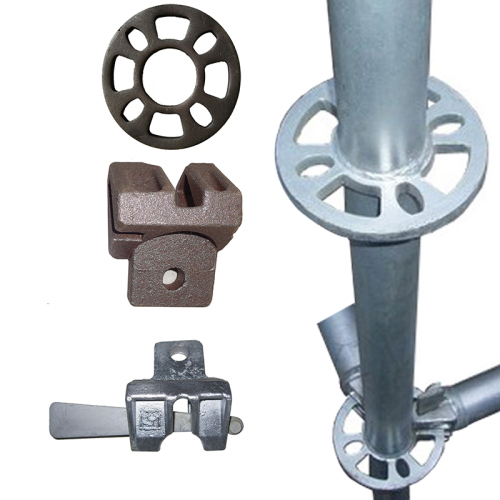

Ringlock scaffolding accessories include a variety of components such as side brackets, guardrails, toe boards, and base plates. These accessories are essential for customizing the scaffolding system to fit specific project requirements and ensuring worker safety.

Key Features of Ringlock Scaffolding Accessories

1. Customization: Accessories allow for flexible configurations, enabling the scaffolding to adapt to complex structures and provide specialized access points.

2. Safety Enhancements: Components like guardrails and toe boards provide comprehensive fall protection, while base plates ensure stability on uneven ground.

3. Durability: Made from high-strength materials, these accessories are designed to withstand heavy-duty applications.

Types of Ringlock Scaffolding Accessories

Ringlock scaffolding accessories can be categorized into several types based on their functions:

1. Side Brackets: These are used to form work platforms and can be adjusted to accommodate different plank widths. They include U-type and O-type brackets, which are essential for suspended scaffolding applications[4].

2. Guardrails and Toe Boards: These provide fall protection on all working platforms and access points, ensuring continuous safety for workers[7].

3. Base Plates and Screw Jacks: These components stabilize the scaffolding on uneven ground, ensuring that the structure remains level and secure[2].

4. Diagonal Braces: These enhance the structural stability of the scaffolding by providing additional support against lateral forces[1].

Suitability for Heavy-Duty Applications

Ringlock scaffolding accessories are designed to support heavy-duty applications due to their robust design and high load-bearing capacity. Here are some reasons why:

1. Material Strength: Accessories are typically made from high-strength steel, such as Q235/Q345, ensuring durability and strength[1].

2. Customization Options: The modular design allows for flexible configurations, enabling the scaffolding to fit complex structures and provide specialized access points[7].

3. Safety Enhancements: Accessories like guardrails and toe boards enhance worker safety by providing comprehensive fall protection[7].

Load Capacity and Structural Stability

Ringlock scaffolding accessories contribute to the overall load capacity of the scaffolding system. The load-bearing capacity depends on factors such as material strength, tube diameter, and bay size[2][5].

Load Capacity Test Results

Load capacity tests have shown that ringlock scaffolding can support substantial weights. For example, a well-assembled four-leg ringlock scaffold tower can typically support up to 10,000 kg (10 metric tons), provided that it is properly braced and supported on a solid foundation[2].

Safety Considerations

Safety is paramount when using ringlock scaffolding accessories. Here are some key safety considerations:

1. Fall Protection: Integral guardrails and toe boards provide comprehensive fall protection on all working platforms and access points.

2. Stable Work Area: The modular frames lock together securely, preventing loose components that could cause accidents.

3. Compliance with Safety Standards: Ringlock scaffolding meets or exceeds safety certifications from organizations like OSHA, ensuring compliance with regulatory requirements.

Customization and Adaptability

One of the significant advantages of ringlock scaffolding accessories is their ability to adapt to complex project geometries. The system allows for flexible configurations, enabling it to fit irregular structures and provide specialized access points.

Environmental Considerations

Ringlock scaffolding accessories can be used on uneven ground or slopes, making them suitable for projects in challenging terrains. The modular design allows for precise adjustments, ensuring stability even in adverse conditions.

Cost Efficiency and Logistics

The modular design of ringlock scaffolding accessories not only enhances safety and stability but also offers cost benefits. The quick assembly and disassembly process reduces labor costs, while the lightweight components make storage and transportation more efficient.

Comparison with Other Scaffolding Accessories

Ringlock scaffolding accessories are often compared to other modular systems like Cuplock and Octagonlock scaffolding. Each system has its unique advantages:

- Ringlock Scaffolding Accessories: Known for their versatility and ease of assembly, they are ideal for complex structures and high-rise projects.

- Cuplock Scaffolding Accessories: Offer simplicity and strength, suitable for straightforward support and access scaffolding.

- Octagonlock Scaffolding Accessories: Provide enhanced stability and are preferred for large industrial constructions requiring maximum support.

Case Studies: Heavy-Duty Applications

Ringlock scaffolding accessories have been successfully used in various heavy-duty projects, including oil and gas refineries and large-scale industrial maintenance works. Their adaptability and strength make them a preferred choice for such applications.

Maintenance and Durability

Ringlock scaffolding accessories are typically made from high-strength materials and are designed to withstand heavy-duty applications. Regular maintenance involves inspecting components for damage and ensuring all connections are secure.

Ensuring Safety During Assembly and Disassembly

Ensuring safety during assembly and disassembly involves several key steps:

1. Proper Training: Ensure that all workers are trained in the assembly and disassembly process.

2. Safety Equipment: Use appropriate safety gear such as hard hats, safety gloves, and harnesses.

3. Stable Ground Conditions: Ensure the scaffolding is erected on stable ground to prevent tilting or sinking.

Conclusion

Ringlock scaffolding accessories are well-suited for heavy-duty applications due to their robust design, high load-bearing capacity, and adaptability. By understanding how these accessories enhance safety and stability, construction teams can optimize their use in complex projects.

FAQ

1. What are the primary types of ringlock scaffolding accessories?

The primary types include side brackets, guardrails, toe boards, and base plates. These components are essential for customizing the scaffolding system and ensuring worker safety.

2. How do ringlock scaffolding accessories enhance worker safety?

Ringlock scaffolding accessories enhance worker safety through features like advanced guardrails and toe boards, providing comprehensive fall protection during assembly and use.

3. What types of projects are ringlock scaffolding accessories suitable for?

Ringlock scaffolding accessories are suitable for a wide range of projects, including high-rise buildings, bridges, infrastructure projects, and industrial maintenance and renovation works.

4. How do the materials used in ringlock scaffolding accessories impact their durability?

The materials used, such as high-strength steel (Q235/Q345), ensure durability and strength, making them suitable for heavy-duty applications.

5. What are the benefits of using ringlock scaffolding accessories in terms of cost efficiency?

The modular design of ringlock scaffolding accessories reduces labor costs through quick assembly and disassembly, while their lightweight nature makes storage and transportation more efficient.

Citations:

[1] https://www.ajbuildscaffold.com/heavy-duty-q345-galvanized-layher-steel-ringlock-scaffold

[2] https://shelterrc.com/what-is-the-load-capacity-of-ringlock-scaffolding/

[3] https://www.youtube.com/watch?v=tnec3rM5kQE

[4] https://www.wm-scaffold.com/ring-lock-scaffold.html

[5] https://scafotech.com/what-is-the-load-capacity-of-ringlock-scaffolding/

[6] https://www.youtube.com/watch?v=LMAyZ20Ww10

[7] https://www.doka.com/en/system-groups/doka-working-scaffold-systems/working-scaffolds/ringlock/ringlock

[8] https://rapid-scafform.com/ringlock-scaffolding/

[9] https://www.shutterstock.com/search/ring-lock-scaffold