Content Menu

● Understanding the Scaffolding End Frame

● Types of Scaffolding End Frames and Frame Systems

>> Common Frame Systems

● Are Scaffolding End Frames Universally Compatible?

>> The Reality of Compatibility

>> Industry Standards and Guidelines

● When Are Scaffolding End Frames Interchangeable?

>> Within the Same System or Manufacturer

>> Between Select Industry-Standard Systems

● Critical Factors Affecting Compatibility

>> 1. Tube Diameter and Wall Thickness

>> 2. Coupling Pins and Lock Pins

>> 3. Cross Brace Attachment

>> 4. Frame Height and Width

>> 5. Manufacturer's Recommendations

● Best Practices for Using Scaffolding End Frames

● Assembly and Safe Use of Scaffolding End Frames

● Scaffolding End Frame as Access Ladders

● Expanding the Discussion: Digital Planning, Sustainability, and Lifecycle Management

>> Digital Planning and BIM Integration

>> Sustainability and Reusability

>> Training and Safety Culture

● Innovations and Trends in Scaffolding End Frame Design

● Conclusion

● FAQ

>> 1. Can scaffolding end frames from different manufacturers be used together?

>> 2. Are all scaffolding end frames suitable for use as ladders?

>> 3. What are the main differences between Safeway, Waco, and Bil-Jax end frames?

>> 4. How can I identify which frame system my scaffolding end frame belongs to?

>> 5. What is the safest practice when assembling scaffolding with end frames?

The scaffolding end frame is a fundamental element in frame scaffolding systems, serving as both a structural support and, often, as an access point for workers. As construction projects become more complex and modularity becomes increasingly important, a critical question arises: can scaffolding end frames be used interchangeably across all frame systems? This article explores the compatibility, standards, and best practices surrounding scaffolding end frames, supported by technical insightsand a comprehensive FAQ.

Understanding the Scaffolding End Frame

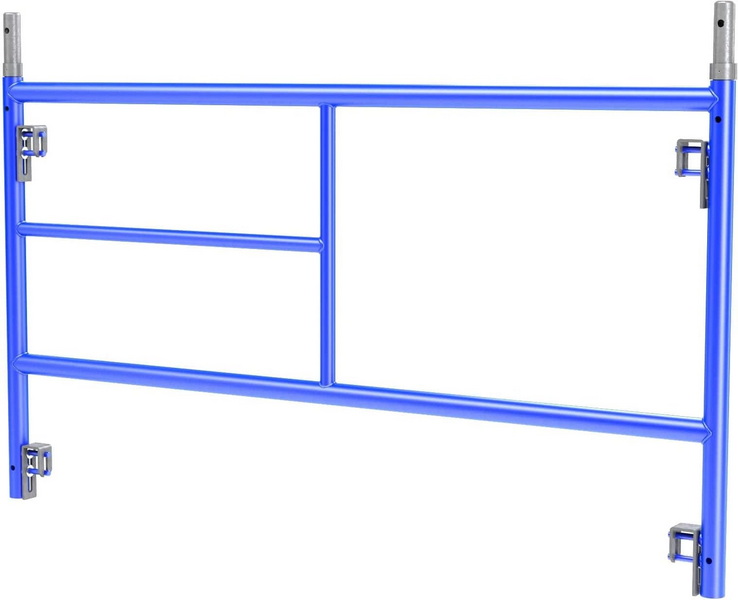

A scaffolding end frame is the vertical component at the end of a scaffold bay. It provides both the structural framework for the scaffold and, in many designs, integrated ladder access for workers. End frames come in various styles, including walk-thru, ladder, and box frames, and are manufactured in different sizes, tube diameters, and locking mechanisms to suit specific applications.

Types of Scaffolding End Frames and Frame Systems

Common Frame Systems

- Safeway Style (Blue): Popular in the southern and southwestern U.S., with distinctive leg diameters and pin hole placements.

- Waco Style (Red): Features unique coupling pin sizes and candy cane drop locks.

- Bil-Jax Style (Yellow): Known for different pin locations and frame dimensions.

- Universal/Modular Frames: Designed for broader compatibility, often used in rental fleets and large projects.

Each system has its own specifications for tube diameter, pin locations, and brace locks, which directly impact the interchangeability of scaffolding end frames.

Are Scaffolding End Frames Universally Compatible?

The Reality of Compatibility

No, scaffolding end frames are not universally compatible with all frame systems. Compatibility depends on several key factors:

- Tube Diameter: Even small differences (e.g., 1-7/16" vs. 1-3/8") can prevent frames from stacking or connecting securely.

- Pin Hole Locations: The orientation and spacing of pin holes affect how frames and coupling pins align.

- Locking Mechanisms: Drop locks, candy cane locks, flip locks, and v-locks differ by system.

- Brace Stud Spacing: Cross brace attachment points vary, impacting which braces can be used.

Mixing components from different manufacturers or frame systems without proper verification can compromise structural integrity and safety.

Industry Standards and Guidelines

- OSHA (U.S.) allows mixing components from different manufacturers only if a competent person determines the resulting scaffold is structurally sound.

- SSFI and SIA provide additional guidance, but always defer to manufacturer recommendations and engineering judgment.

- ISO and ANSI/OSHA Compliance: Most reputable manufacturers design their scaffolding end frames to meet or exceed these standards, but this does not guarantee cross-system compatibility.

When Are Scaffolding End Frames Interchangeable?

Within the Same System or Manufacturer

- Full Compatibility: End frames, braces, and accessories from the same manufacturer and system are designed to work together, ensuring safety and ease of assembly.

- Color Coding and Markings: Many suppliers use color codes (e.g., blue for Safeway, red for Waco) and stamped markings to help users identify compatible parts.

Between Select Industry-Standard Systems

Some manufacturers design their scaffolding end frames and accessories to be compatible with other leading brands and industry-standard patterns. For example, DSS B-Size (Red) accessories are fully compatible with other leading frame systems, and ScaffoldMart's yellow frames are compatible with most systems.

- Interchangeable Frames: Aluminum and steel frames from reputable suppliers may be compatible with other major patterns, especially for standard sizes and lock spacing.

- Caveats: Even with stated compatibility, always verify tube diameters, pin locations, and lock types before mixing components.

Critical Factors Affecting Compatibility

1. Tube Diameter and Wall Thickness

A mismatch in tube diameter or wall thickness can prevent proper stacking and compromise load capacity.

2. Coupling Pins and Lock Pins

Different systems use different pin diameters, lengths, and locking features, affecting vertical stacking and stability.

3. Cross Brace Attachment

The spacing and type of brace locks (drop lock, candy cane, flip lock) must match between the end frame and the brace.

4. Frame Height and Width

Variations in frame dimensions can lead to uneven platforms and unsafe working conditions if mixed improperly.

5. Manufacturer's Recommendations

Always consult the manufacturer's documentation or engineering department to confirm compatibility—especially for critical components like the scaffolding end frame.

Best Practices for Using Scaffolding End Frames

- Use Matched Systems: Whenever possible, use end frames and accessories from the same manufacturer and system.

- Competent Person Inspection: If mixing is necessary, have a competent person inspect the assembly for structural soundness, as required by OSHA.

- Label and Organize: Clearly label frames and accessories by system to avoid accidental mixing on site.

- Regular Inspection: Inspect all scaffolding end frames for damage, wear, and compatibility before use.

Assembly and Safe Use of Scaffolding End Frames

Proper assembly is crucial for safety and performance:

- Level Base: Set frames on level, stable base plates or mud sills.

- Secure Bracing: Attach cross and diagonal braces according to manufacturer instructions.

- Lock Pins: Insert lock pins through coupling pins and frame legs to prevent separation.

- Access: Use only end frames specifically designed for ladder access if using as a means of ascent.

Scaffolding End Frame as Access Ladders

OSHA recognizes “integral prefabricated scaffold access” frames (built-in ladder rungs) as an acceptable means of access, provided they meet specific requirements:

- Rung Length: At least 8 inches.

- Rung Spacing: No more than 16 ¾ inches.

- Rest Platforms: Required every 35 feet of vertical height.

- Design: Must be specifically designed and constructed for use as ladder rungs.

Not all scaffolding end frames are designed for climbing; always verify with the manufacturer.

Expanding the Discussion: Digital Planning, Sustainability, and Lifecycle Management

Digital Planning and BIM Integration

Modern construction increasingly leverages digital tools and Building Information Modeling (BIM) to manage scaffolding layouts and compatibility:

- 3D Visualization: BIM allows project managers to model scaffolding systems, including scaffolding end frame compatibility, before assembly.

- Clash Detection: Digital planning identifies potential mismatches between end frames and other system components.

- Documentation: Digital records streamline inspection, maintenance, and regulatory compliance.

Sustainability and Reusability

Scaffolding end frames are designed for repeated use, supporting sustainable construction:

- Durable Materials: Galvanized and powder-coated finishes extend service life and reduce waste.

- Efficient Logistics: Modular end frames are easy to transport, store, and redeploy across multiple projects.

- Lifecycle Management: Regular inspection and maintenance ensure continued safety and compliance.

Training and Safety Culture

Proper training is essential for safe use of scaffolding end frames:

- Certification Programs: Industry associations and manufacturers offer training on system identification, assembly, and inspection.

- On-Site Supervision: Competent persons oversee assembly and check for compatibility.

- Safety Audits: Regular audits reinforce best practices and catch compatibility issues early.

Innovations and Trends in Scaffolding End Frame Design

- Powder Coating and Galvanization: Enhanced corrosion resistance and durability for longer service life.

- Modular Accessories: Side brackets, guardrails, and adjustable bases for increased versatility.

- Digital Planning: BIM and 3D modeling tools for scaffold layout and compatibility checks.

- Smart Tagging: RFID or barcode tracking for inventory management and lifecycle tracking.

Conclusion

The scaffolding end frame is a vital component of safe and efficient frame scaffolding systems. While some end frames are designed for compatibility with multiple systems, universal interchangeability cannot be assumed due to differences in tube diameter, pin placement, lock mechanisms, and manufacturer specifications. For best results, use matched systems or consult with a competent person and the manufacturer before mixing components. Always prioritize safety, compliance, and clear communication on site to ensure your scaffolding end frames perform as intended.

FAQ

1. Can scaffolding end frames from different manufacturers be used together?

Generally, only if a competent person verifies structural soundness and compatibility. Tube diameter, pin locations, and lock mechanisms must match; otherwise, mixing can be unsafe.

2. Are all scaffolding end frames suitable for use as ladders?

No. Only end frames specifically designed and constructed for ladder access, with compliant rung spacing and length, should be used for climbing.

3. What are the main differences between Safeway, Waco, and Bil-Jax end frames?

They differ in leg diameter, pin hole placement, and brace lock style. Each is generally compatible only with its own system, though some accessories are cross-compatible.

4. How can I identify which frame system my scaffolding end frame belongs to?

Look for color coding, manufacturer markings, and compare tube diameters and lock types. When in doubt, consult supplier documentation or engineering support.

5. What is the safest practice when assembling scaffolding with end frames?

Use all components from the same system and manufacturer. If mixing is unavoidable, have a competent person inspect the assembly for compatibility and structural safety, and follow all OSHA and manufacturer guidelines.