Content Menu

● Introduction to Layher Scaffold Systems

● Key Features of Layher Scaffold Systems

● Benefits of Layher Scaffold Systems in Enhancing Construction Efficiency

● Applications of Layher Scaffold Systems in Diverse Construction Projects

● Case Studies Demonstrating Efficiency Gains

● Safety Features of Layher Scaffold Systems

● Conclusion

● FAQ

>> 1. What is the Layher scaffold system and what are its key features?

>> 2. How does the Layher scaffold system improve efficiency in construction projects?

>> 3. What types of construction projects are suitable for Layher scaffold systems?

>> 4. What safety features are incorporated into Layher scaffold systems?

>> 5. How does the modular design of the Layher scaffold system contribute to its efficiency?

● Citations:

In the fast-paced and demanding world of construction, efficiency is paramount. Every minute saved, every process streamlined, and every task optimized contributes to project success. Time is, quite literally, money in this industry. One of the most significant factors influencing construction efficiency is the scaffolding system employed. The right system can drastically reduce labor costs, improve safety, and accelerate project completion. Among the various options available, the Layher scaffold system stands out as a leading solution for enhancing efficiency in construction projects of all scales. This article explores the numerous ways in which the Layher scaffold system improves efficiency, from its innovative design to its safety features and versatile applications. We'll also delve into specific examples and benefits that showcase why Layher is often the preferred choice for demanding construction projects.

Introduction to Layher Scaffold Systems

The Layher scaffold system is a modular scaffolding solution renowned for its versatility, safety, and speed of assembly. Originating in Germany, Layher has become a global leader in scaffolding technology, offering a comprehensive range of products designed to meet the diverse needs of the construction industry. The system is characterized by its rosette connection point, which allows for flexible and secure connections between components at various angles. This modularity, combined with lightweight yet robust materials, enables rapid erection and dismantling, significantly reducing project timelines and labor costs. Layher's continuous innovation ensures that their scaffolding solutions are always at the forefront of the industry.

Key Features of Layher Scaffold Systems

Several key features contribute to the efficiency gains offered by the Layher scaffold system:

- Modular Design: The modularity of the Layher system allows for easy adaptation to a wide range of project requirements and site conditions. This adaptability reduces the need for custom fabrication and allows for efficient use of components. Whether you're working on a curved facade or a complex industrial structure, Layher's modularity allows for a tailored scaffolding solution.

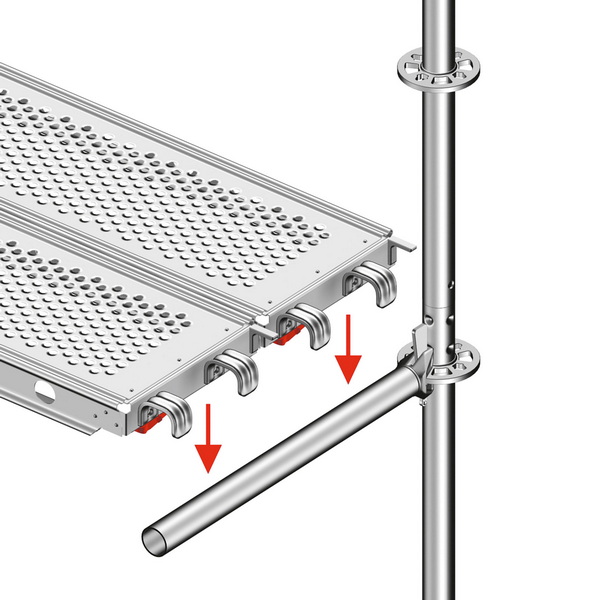

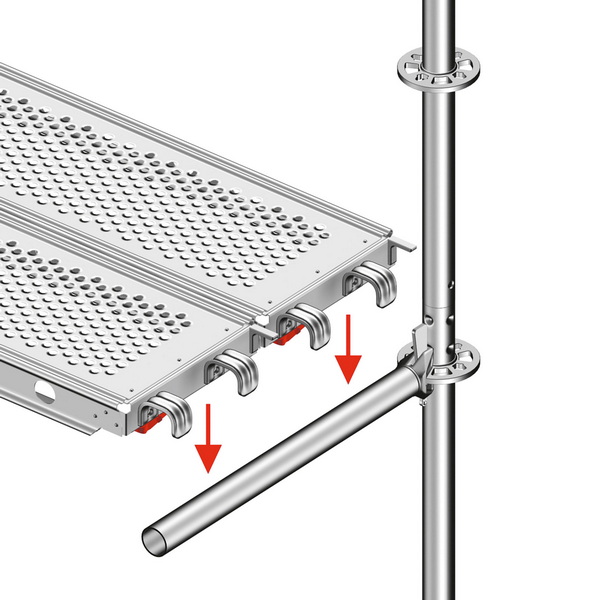

- Rosette Connection: The rosette connection point enables quick and secure connections between components at various angles. This design simplifies assembly and disassembly, saving time and labor. The rosette system provides a strong and reliable connection that can withstand heavy loads and challenging weather conditions.

- Lightweight Materials: Layher scaffolding is often constructed from lightweight materials, such as high-grade aluminum and high-tensile steel. This reduces the weight of components, making them easier to handle and transport, further accelerating the erection process. Lightweight materials also reduce the strain on workers, improving safety and productivity.

- Integrated Safety Features: Layher systems incorporate numerous safety features, such as integrated guardrails, lock-in decks, and secure access solutions. These features reduce the risk of accidents and ensure a safe working environment, minimizing downtime and improving overall efficiency. Safety features are seamlessly integrated into the design of the Layher system, making them easy to use and maintain.

- Bolt-Free System: The Layher team has developed a bolt-free system that delivers a combination of positive and non-positive connections. This system reduces the number of components required to assemble scaffolding structures which results in faster erection and dismantling time. The bolt-free design simplifies the assembly process and reduces the risk of errors.

Benefits of Layher Scaffold Systems in Enhancing Construction Efficiency

The Layher scaffold system enhances construction efficiency in several key ways:

- Faster Erection and Dismantling: The modular design, rosette connection, and lightweight materials of the Layher system enable rapid erection and dismantling. This reduces project timelines and labor costs, contributing to significant efficiency gains. Layher scaffolding systems can save more than 30% time during assembly and dismantling when compared with structures made of individual components. Faster setup and takedown means less disruption to other trades working on the site.

- Reduced Labor Costs: The speed of assembly and disassembly, combined with the reduced number of components, translates to lower labor costs. Fewer workers are required to erect and dismantle the scaffolding, freeing up resources for other critical tasks. Reduced labor costs are a significant advantage, especially on large-scale projects with tight budgets.

- Improved Safety: Layher's dedication to fulfill and exceed every safety standard gives those who insist on Layher scaffolding the certainty they are able to work with confidence. The integrated safety features of Layher systems reduce the risk of accidents and ensure a safe working environment. This minimizes downtime and improves overall productivity. A safe work environment leads to higher morale and reduced worker turnover.

- Increased Versatility: The modular design of the Layher system allows for easy adaptation to a wide range of project requirements and site conditions. This versatility eliminates the need for custom fabrication and enables efficient use of components. Versatility translates to greater flexibility and the ability to adapt to unexpected challenges on the job site.

- Optimized Material Handling: The lightweight materials used in Layher scaffolding reduce the effort required for material handling. This minimizes worker fatigue and improves overall productivity. Optimized material handling reduces the risk of injuries and improves overall workflow.

- Reduced Number of Components: Through its commitment to R&D, Layher has reduced the number of components required to assemble scaffolding structures. Fewer components equal more simple structures resulting in faster erection and dismantling time. A simplified system reduces the risk of errors during assembly and disassembly.

- Enhanced Project Planning and Management: The Layher system enables more precise project planning and management due to its predictable assembly and disassembly times. This allows project managers to accurately schedule tasks and allocate resources effectively. Improved project planning leads to better communication and coordination among all stakeholders.

- Adaptability to Complex Geometries: Layher scaffold system is designed to handle complex geometries with ease, making it ideal for projects involving curved surfaces, intricate facades, or irregular structures. This level of adaptability minimizes the need for custom solutions, saving time and money.

Applications of Layher Scaffold Systems in Diverse Construction Projects

The Layher scaffold system is suitable for a wide range of construction projects, including:

- Residential Buildings: Layher scaffolding provides safe and efficient access for construction, renovation, and repair of residential buildings. Its modular design allows for easy adaptation to various building geometries. From single-family homes to multi-story apartments, Layher can provide a tailored scaffolding solution.

- Commercial Buildings: Layher systems offer versatile solutions for the construction and maintenance of commercial buildings, providing stable and secure platforms for workers and materials. Office towers, shopping malls, and hotels can all benefit from Layher's efficiency and safety.

- Industrial Facilities: Layher scaffolding is ideal for industrial applications, offering robust and reliable support for heavy loads and complex structures. Power plants, refineries, and manufacturing facilities require scaffolding systems that can withstand demanding conditions.

- Infrastructure Projects: Layher systems can be used for bridge construction, maintenance, and repair, providing safe and efficient access for workers and equipment. Bridges, tunnels, and dams all require specialized scaffolding solutions that can handle unique challenges.

- Event Structures: Layher scaffolding can be used to create temporary structures for events, providing safe and reliable support for stages, seating areas, and other event infrastructure. Concerts, festivals, and sporting events often require temporary structures that can be quickly assembled and dismantled.

- Shipbuilding and Repair: Layher scaffolding provides safe and versatile solutions for shipbuilding and repair operations, enabling workers to access all areas of the vessel with ease.

Case Studies Demonstrating Efficiency Gains

While specific case studies are not provided in the search results, the general benefits outlined suggest significant efficiency gains in various scenarios. For example, consider a high-rise construction project where rapid erection and dismantling of scaffolding are critical. By using a Layher scaffold system, the construction team can save valuable time and labor, accelerating the project timeline and reducing overall costs. Similarly, in a bridge repair project, Layher scaffolding can provide safe and efficient access for workers, minimizing disruption to traffic and reducing the overall project duration.

Safety Features of Layher Scaffold Systems

Layher places a strong emphasis on safety, incorporating numerous features to protect workers and minimize the risk of accidents:

- Advanced Guardrail Systems: Layher offers advanced guardrail systems that provide a secure barrier along the edges of the platform, preventing falls. These systems are designed for easy installation and removal, further enhancing efficiency.

- Lock-in Decks: Lock-in decks prevent accidental dislodgement of the platform, ensuring a stable and secure working surface. This feature is particularly important in windy conditions or when working with heavy materials.

- Secure Access Solutions: Layher provides various secure access solutions, such as stairways and ladders with anti-slip rungs, to facilitate safe movement within the scaffolding structure. Secure access is essential for preventing slips, trips, and falls.

- Tried & Tested: All Layher products undergo rigorous testing to ensure on-site safety, strength, and stability across the entire range. This commitment to quality and safety provides peace of mind to construction professionals.

- Compliance with Safety Standards: Layher scaffolding systems are designed to comply with all relevant safety standards and regulations, ensuring that construction projects meet legal requirements.

Conclusion

The Layher scaffold system offers a multitude of benefits that enhance efficiency in construction projects. Its modular design, rosette connection, lightweight materials, and integrated safety features enable rapid erection and dismantling, reduced labor costs, improved safety, increased versatility, and optimized material handling. By choosing a Layher scaffold system, construction companies can significantly improve their productivity, reduce project timelines, and ensure a safer working environment for their employees. Layher systems deliver profit through a reduction in shutdown times. As the construction industry continues to evolve, innovative solutions like the Layher scaffold system will play an increasingly vital role in driving efficiency and success.

FAQ

1. What is the Layher scaffold system and what are its key features?

The Layher scaffold system is a modular scaffolding solution known for its versatility, safety, and speed of assembly. Key features include a modular design, rosette connection, lightweight materials, and integrated safety features.

2. How does the Layher scaffold system improve efficiency in construction projects?

The Layher scaffold system improves efficiency through faster erection and dismantling, reduced labor costs, improved safety, increased versatility, and optimized material handling.

3. What types of construction projects are suitable for Layher scaffold systems?

Layher scaffold systems are suitable for a wide range of construction projects, including residential buildings, commercial buildings, industrial facilities, infrastructure projects, and event structures.

4. What safety features are incorporated into Layher scaffold systems?

Layher scaffold systems incorporate advanced guardrail systems, lock-in decks, secure access solutions, and other safety features to protect workers and minimize the risk of accidents.

5. How does the modular design of the Layher scaffold system contribute to its efficiency?

The modular design of the Layher system allows for easy adaptation to a wide range of project requirements and site conditions, reducing the need for custom fabrication and enabling efficient use of components. This results in significant time and cost savings.

Citations:

[1] https://layher.ca

[2] https://www.leadingedgescaffolding.com.au/post/five-reasons-why-layher-is-a-top-choice-for-scaffolding-hirein-melbourne

[3] https://layherna.com/scaffold-safety/

[4] https://www.mastascaffold.com.au/layherscaffold

[5] https://www.uprightscaffolding.co.nz/blog/why-upright-scaffolding-use-premium-scaffolding-equipment/

[6] https://www.layher.co.nz/scaffold-safety-solutions/

[7] https://layherna.com/allround-scaffolding/

[8] https://layherna.com/why-layher-scaffolding-systems/

[9] https://www.sidewall.co.nz/blog/layher-scaffolding-system/

[10] https://specialisedaccessandscaffolding.com.au/layher/