Content Menu

● Understanding the Pole Scaffolding System

● Key Components of a Pole Scaffolding System

● Enhancing Safety with Pole Scaffolding Systems

>> Stable Foundation

>> Robust Structural Integrity

>> Fall Prevention Measures

>> Load Capacity Management

● Stability Enhancements in Pole Scaffolding Systems

>> Cross Bracing

>> Increasing Standards

>> Firm Foundation

>> Double or Independent Scaffolding

● Advantages of Pole Scaffolding Systems

>> Adaptability

>> Cost-Effectiveness

>> Portability

● Disadvantages of Pole Scaffolding Systems

>> Material Limitations

>> Lower Load Capacity

>> Labor Intensive

● Best Practices for Using Pole Scaffolding Systems

● Conclusion

● FAQ

>> 1. What is a pole scaffolding system?

>> 2. How does pole scaffolding enhance safety?

>> 3. What are the key components of a pole scaffolding system?

>> 4. What are the advantages and disadvantages of using pole scaffolding?

>> 5. What are the best practices for ensuring safety when using pole scaffolding?

● Citations:

Pole scaffolding, also known as wood pole scaffolding, represents one of the oldest forms of scaffolding and continues to be utilized in various construction and maintenance projects, particularly in situations demanding adaptability and cost-effectiveness[4]. Understanding how a pole scaffolding system enhances safety and stability is crucial for ensuring worker well-being and project success. This article explores the design, components, advantages, and safety considerations associated with pole scaffolding systems, shedding light on how it contributes to a secure and stable working environment.

Understanding the Pole Scaffolding System

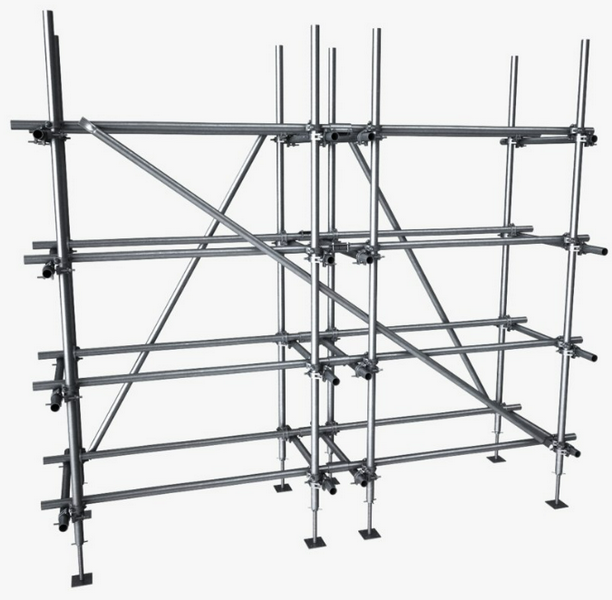

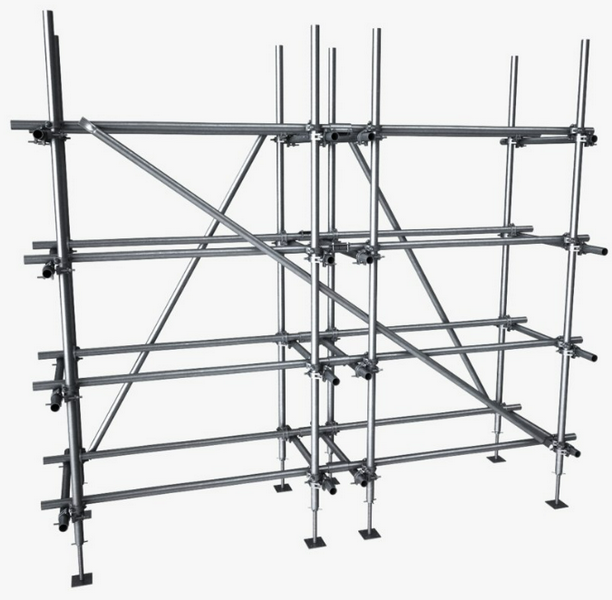

A pole scaffolding system is primarily constructed from wooden poles, which serve as vertical supports, along with horizontal members (ledgers) and diagonal braces[4]. These components are interconnected to create a temporary structure that provides a stable platform for workers and materials at elevated heights. While modern materials like steel and aluminum are prevalent in many scaffolding systems, pole scaffolding remains a viable option due to its simplicity and adaptability, especially in regions where wood is readily available and cost-effective[4].

Key Components of a Pole Scaffolding System

- Poles (Standards): Vertical wooden poles that serve as the primary supports for the scaffolding structure[4].

- Ledgers: Horizontal members that connect the poles, providing lateral support and a base for the platform[4].

- Braces: Diagonal members that add strength and rigidity to the structure, preventing swaying and collapse[4].

- Putlogs: Short horizontal members that extend from the ledgers to support the platform[4].

- Platforms (Walkboards): Horizontal surfaces made of wooden planks where workers stand and perform their tasks[4].

- Guardrails: Safety barriers installed along the edges of the platform to prevent falls[4].

- Toeboards: Short boards placed along the platform's edge to prevent tools and materials from falling [4, 6].

- Base Plates: Plates that distribute the load of the poles to the ground, preventing sinking [2, 5].

Enhancing Safety with Pole Scaffolding Systems

Stable Foundation

A stable foundation is paramount for any scaffolding system, and pole scaffolding is no exception. Proper footing is essential to ensure the scaffold does not collapse. The foundation must be square and level to avoid risk[5]. To achieve this, pole scaffolding systems typically utilize base plates and mud sills to distribute the load evenly and prevent settling or displacement[5].

- Base Plates: Distribute the load of the poles to the ground, preventing them from sinking into soft soil [2, 5].

- Mud Sills: Provide a firm and level base, especially on uneven or unstable ground[5].

- Leveling: Ensuring the base is level is crucial for maintaining the overall stability of the pole scaffolding system[5].

Robust Structural Integrity

The structural integrity of a pole scaffolding system is enhanced through careful selection and arrangement of its components. The poles, ledgers, and braces work together to create a rigid framework that can withstand vertical and lateral forces.

- Proper Bracing: Diagonal braces provide essential support against swaying and twisting, maintaining the scaffold's shape and preventing collapse [2, 4].

- Secure Connections: Ensuring that all connections between poles, ledgers, and braces are secure is critical for maintaining structural integrity[5].

- Quality Materials: Using sturdy wooden poles and planks that are free from defects ensures the scaffold can bear the intended loads [4, 5].

Fall Prevention Measures

Falls are a significant hazard in construction, and pole scaffolding systems incorporate several measures to prevent them. Guardrails, toeboards, and safety nets are essential components that protect workers from falling off the platform [3, 4, 6].

- Guardrails: Serve the vital purpose of preventing workers from falling off open sides and ends of platforms [3, 6].

- Toeboards: Prevent tools and materials from falling from the platform's edge, protecting workers below [4, 6].

- Safety Nets: Provide an additional layer of protection by catching workers or materials that may fall from the scaffold[3].

Load Capacity Management

Overloading a scaffolding system can lead to catastrophic collapses. Pole scaffolding systems must be designed and used within their load capacity limits to ensure safety[6].

- Load Calculation: Calculating the maximum intended load, including workers, materials, and equipment, is essential for determining the appropriate scaffolding configuration [2, 6].

- Weight Distribution: Distributing the load evenly across the platform helps prevent concentrated stress on any single component[2].

- Regular Inspections: Regularly inspecting the scaffold for signs of overloading or structural weakness is crucial for maintaining safety[5].

Stability Enhancements in Pole Scaffolding Systems

Cross Bracing

Cross bracing involves the use of diagonal supports that intersect to form an "X" pattern. This technique significantly enhances the lateral stability of the pole scaffolding system, preventing it from swaying or collapsing under lateral loads[2].

Increasing Standards

Increasing the number of vertical scaffolding poles (standards) enhances the overall stability of the platform[2]. This reduces the load on each individual pole and distributes the weight more evenly, improving the scaffold's ability to withstand heavy loads.

Firm Foundation

Footings must be capable of supporting the loaded scaffold without settling or displacement[5]. Supported scaffold poles, frames, uprights, etc. must be set on a base plate and mud sill or other firm foundation and must be plumb and braced to prevent swaying and displacement[5].

Double or Independent Scaffolding

Double or independent scaffolding is a sturdy and reliable scaffold type known for its stability on uneven ground and its strength in various construction projects[7].

Advantages of Pole Scaffolding Systems

Adaptability

Pole scaffolding systems are highly adaptable, making them suitable for projects with unique or irregular structures[4]. The ability to adjust the height and configuration of the scaffold allows workers to access difficult-to-reach areas with ease [1, 9].

Cost-Effectiveness

In regions where wood is readily available, pole scaffolding can be a more cost-effective option compared to systems that rely on expensive metal components[4].

Portability

Pump jack scaffolding is an adaptable tool that allows for indoor or outdoor use due to its lightweight and easy movement[1]. Users can quickly assemble and disassemble it, making it flexible for deployment on different job sites[1].

Disadvantages of Pole Scaffolding Systems

Material Limitations

Wooden poles are susceptible to deterioration from weather and pests, which can compromise the structural integrity of the pole scaffolding system[5].

Lower Load Capacity

Compared to steel or aluminum scaffolding, pole scaffolding typically has a lower load-bearing capacity, limiting its use in heavy construction projects[6].

Labor Intensive

Pole scaffolding requires more on-site labor for assembly and disassembly compared to pre-engineered systems, increasing labor costs[4].

Best Practices for Using Pole Scaffolding Systems

1. Material Inspection: Inspect all wooden poles and planks for defects, such as cracks, knots, or decay, before use[5].

2. Proper Assembly: Follow a detailed assembly plan to ensure that all components are correctly installed and securely connected[5].

3. Regular Inspections: Conduct regular inspections of the scaffold to identify any signs of damage or instability[5].

4. Load Management: Adhere to the scaffold's load capacity limits and distribute weight evenly across the platform[6].

5. Weather Precautions: Take extra precautions during adverse weather conditions, such as high winds or heavy rain, to prevent accidents[2].

6. Worker Training: Ensure that all workers are properly trained in the safe use of pole scaffolding systems, including fall prevention measures and load management techniques[3].

Conclusion

Pole scaffolding systems offer a range of benefits in terms of adaptability and cost-effectiveness, particularly in regions where wood is readily available. When properly designed, assembled, and maintained, pole scaffolding can provide a safe and stable working environment for construction and maintenance projects [1, 3, 9]. Adhering to best practices for material selection, assembly, inspections, and load management is crucial for maximizing safety and stability [5, 6]. While pole scaffolding may not be suitable for all projects due to its material limitations and labor intensity, it remains a viable option for certain applications where its advantages outweigh its drawbacks[4].

FAQ

1. What is a pole scaffolding system?

A pole scaffolding system is a temporary structure constructed primarily from wooden poles, used to provide a stable platform for workers and materials at elevated heights[4].

2. How does pole scaffolding enhance safety?

Pole scaffolding enhances safety through stable foundations, robust structural integrity, fall prevention measures, and load capacity management [3, 5, 6].

3. What are the key components of a pole scaffolding system?

The key components include poles (standards), ledgers, braces, putlogs, platforms, guardrails, and toeboards[4].

4. What are the advantages and disadvantages of using pole scaffolding?

Advantages include adaptability and cost-effectiveness, while disadvantages include material limitations and labor intensity[4].

5. What are the best practices for ensuring safety when using pole scaffolding?

Best practices include material inspection, proper assembly, regular inspections, load management, weather precautions, and worker training [5, 6].

Citations:

[1] https://dss.net/guide-to-pump-jack-scaffolding-types-pros-and-cons/

[2] https://www.discoscaff.co.za/scaffolding-key-safety-measures-for-users/

[3] https://www.sparsteel.com/what-is-scaffolding.html

[4] https://scaffoldtype.com/16-scaffold-types/

[5] https://weeklysafety.com/blog/supported-scaffolds

[6] https://scaffold.com/13-safety-features-designed-into-modern-construction-scaffolds/

[7] https://securescaffold.co.nz/types-benefits-uses-applications-of-scaffolding-used-in-construction/

[8] https://www.alumapole.com/scaffoldmain.html

[9] https://www.flyability.com/blog/scaffolding