Content Menu

● Introduction to Traditional Tube and Clamp Scaffolding

● Components of Traditional Tube and Clamp Scaffolding

● Introduction to Square Tube Scaffolding

● Components of Square Tube Scaffolding

● Comparison of Traditional and Square Tube Scaffolding

>> 1. Structural Integrity and Stability

>> 2. Setup and Dismantling Process

>> 3. Safety Features

>> 4. Applications

● Extended Comparison: Cost, Durability, and Environmental Impact

>> Cost Considerations

>> Durability and Maintenance

>> Environmental Impact

● Case Studies and Real-World Applications

>> Traditional Tube and Clamp Scaffolding in Construction

>> Potential Applications of Square Tube Scaffolding

● Innovations and Future Developments

>> Advanced Materials and Designs

>> Technological Integration

● Conclusion

● FAQ

>> 1. What are the main components of traditional tube and clamp scaffolding?

>> 2. How does square tube scaffolding compare in terms of stability?

>> 3. What are the safety requirements for traditional scaffolding?

>> 4. Are there specific applications where square tube scaffolding is preferred?

>> 5. How does the setup process differ between traditional and square tube scaffolding?

● Citations:

Scaffolding is a crucial component in construction, providing a safe and stable platform for workers to perform tasks at heights. Over the years, scaffolding technology has evolved, offering various types of scaffolding systems, each with its unique advantages and applications. Two common types of scaffolding are traditional tube and clamp scaffolding and square tube scaffolding. This article will delve into the differences and comparisons between these two systems, exploring their components, setup processes, safety features, and applications.

Introduction to Traditional Tube and Clamp Scaffolding

Traditional tube and clamp scaffolding is one of the most widely used scaffolding systems globally. It consists of three basic steel components: tubes, clamps, and base plates. The tubes are typically made from galvanized steel and come in various lengths, while the clamps are used to connect these tubes at different angles. There are two main types of clamps: right-angle clamps for connecting tubes at 90 degrees and swivel clamps for connecting tubes at any angle.

Components of Traditional Tube and Clamp Scaffolding

- Tubes: These are the vertical and horizontal members of the scaffold. They are usually made from galvanized steel to provide durability and resistance to corrosion.

- Clamps: Right-angle and swivel clamps are used to connect tubes. These clamps are tightened to ensure stability and safety.

- Base Plates: These are used to distribute the weight of the scaffold evenly on the ground, providing a stable foundation.

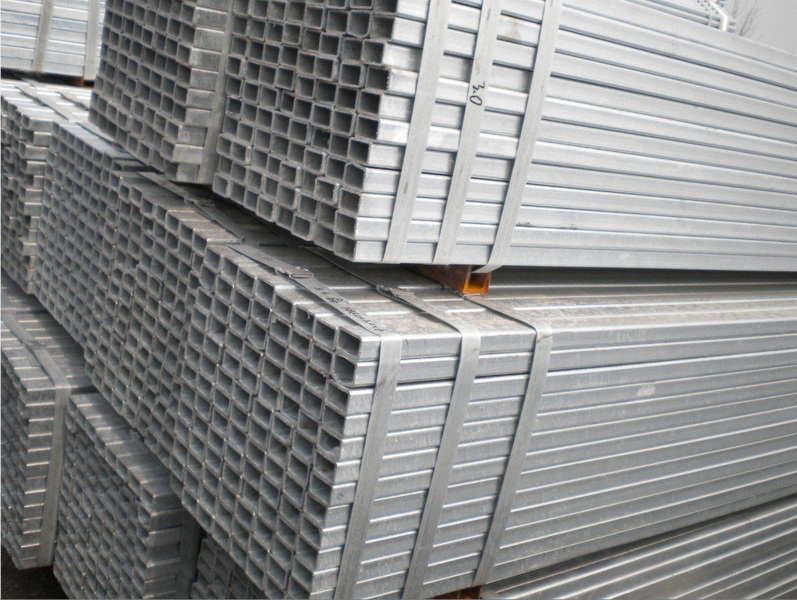

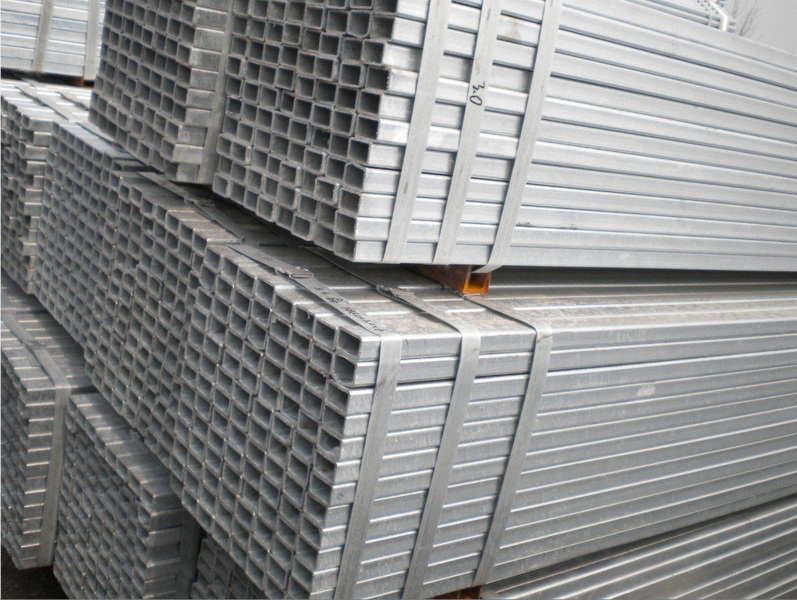

Introduction to Square Tube Scaffolding

Square tube scaffolding, while less common, offers a distinct set of advantages over traditional systems. It uses square tubes instead of round ones, which can provide additional structural strength and stability. However, specific details about square tube scaffolding are less documented compared to traditional systems, and it may not be as widely available or recognized in the industry.

Components of Square Tube Scaffolding

- Square Tubes: These provide a more rigid structure compared to round tubes, potentially offering better stability and load-bearing capacity.

- Clamps and Connectors: Similar to traditional scaffolding, but designed specifically for square tubes.

- Base Plates: Similar to those used in traditional scaffolding, ensuring a stable base.

Comparison of Traditional and Square Tube Scaffolding

1. Structural Integrity and Stability

- Traditional Tube and Clamp Scaffolding: Offers flexibility with the use of swivel clamps, allowing for easy adaptation to irregular surfaces. However, it may require more frequent adjustments to maintain stability.

- Square Tube Scaffolding: Provides a more rigid structure, potentially offering better stability and resistance to deformation under load.

2. Setup and Dismantling Process

- Traditional Tube and Clamp Scaffolding: Easier to set up and dismantle due to the simplicity of the clamp system. It allows for quick adjustments and modifications.

- Square Tube Scaffolding: May require more specialized tools and training due to the unique nature of the square tubes and connectors.

3. Safety Features

- Traditional Tube and Clamp Scaffolding: Well-established safety protocols and regulations are in place, ensuring that scaffolds can support at least four times the maximum intended load.

- Square Tube Scaffolding: While potentially offering better structural integrity, specific safety standards and regulations may vary or be less defined.

4. Applications

- Traditional Tube and Clamp Scaffolding: Widely used in various construction projects due to its versatility and adaptability.

- Square Tube Scaffolding: May be more suitable for projects requiring high structural integrity and stability, though its application might be limited by availability and industry recognition.

Extended Comparison: Cost, Durability, and Environmental Impact

Cost Considerations

- Traditional Tube and Clamp Scaffolding: Generally less expensive to purchase and maintain due to its widespread use and availability.

- Square Tube Scaffolding: May be more costly due to the specialized nature of the square tubes and connectors, though it could offer long-term savings through reduced maintenance needs.

Durability and Maintenance

- Traditional Tube and Clamp Scaffolding: Requires regular maintenance to ensure clamps are secure and tubes are free from damage.

- Square Tube Scaffolding: Potentially more durable due to its rigid structure, which may reduce the need for frequent adjustments and repairs.

Environmental Impact

- Traditional Tube and Clamp Scaffolding: The use of galvanized steel reduces corrosion, making it more environmentally friendly by extending the lifespan of the scaffolding.

- Square Tube Scaffolding: Similar environmental benefits can be expected, though the production process for square tubes might have different environmental implications.

Case Studies and Real-World Applications

Traditional Tube and Clamp Scaffolding in Construction

Traditional scaffolding has been used in numerous iconic construction projects worldwide, such as skyscrapers and historical building renovations. Its versatility allows it to adapt to complex architectural designs and irregular surfaces.

Potential Applications of Square Tube Scaffolding

While square tube scaffolding is less documented, it could be beneficial in projects requiring high structural stability, such as large-scale industrial construction or high-rise buildings where wind resistance is a concern.

Innovations and Future Developments

The scaffolding industry is continuously evolving, with innovations focusing on safety, sustainability, and efficiency. Future developments may include more advanced materials and designs that combine the benefits of both traditional and square tube scaffolding systems.

Advanced Materials and Designs

- Modular Scaffolding Systems: These systems are designed for ease of assembly and disassembly, reducing labor costs and environmental impact.

- Aluminum Scaffolding: Offers lighter weight and corrosion resistance, making it ideal for projects where mobility and ease of setup are crucial.

Technological Integration

- Digital Tools for Scaffold Design: Software can help optimize scaffold design, ensuring safety and efficiency by simulating different configurations and loads.

- Safety Monitoring Systems: Real-time monitoring systems can alert workers and supervisors to potential safety hazards, enhancing overall site safety.

Conclusion

In conclusion, while traditional tube and clamp scaffolding remains the most widely used and versatile system, square tube scaffolding offers unique advantages in terms of structural integrity. However, its adoption may be hindered by limited availability and less defined industry standards. As technology continues to evolve, it will be interesting to see how square tube scaffolding develops and becomes more integrated into the construction industry.

FAQ

1. What are the main components of traditional tube and clamp scaffolding?

The main components include tubes, clamps (right-angle and swivel), and base plates.

2. How does square tube scaffolding compare in terms of stability?

Square tube scaffolding potentially offers better stability due to its rigid structure, though specific data may vary.

3. What are the safety requirements for traditional scaffolding?

Traditional scaffolding must support at least four times the maximum intended load and adhere to specific safety protocols.

4. Are there specific applications where square tube scaffolding is preferred?

Square tube scaffolding might be preferred in projects requiring high structural integrity, though its use is less common.

5. How does the setup process differ between traditional and square tube scaffolding?

Traditional scaffolding is generally easier to set up due to its simpler clamp system, while square tube scaffolding may require specialized tools and training.

Citations:

[1] https://www.youtube.com/watch?v=ZM6Tlh_NAnQ

[2] https://plecoforums.com/download/20180922-sentence-contextual-writing-practice-eng-txt.2714/

[3] https://www.youtube.com/watch?v=_La74H8RUhA

[4] https://www.youtube.com/watch?v=veF4uSUtrEY

[5] https://www.istockphoto.com/videos/scaffolding-tube

[6] https://www.shutterstock.com/video/search/scaffolding

[7] https://www.shutterstock.com/search/tubular-scaffold

[8] https://www.istockphoto.com/photos/stack-scaffolding-pipe-construction-site