Content Menu

● Introduction to the German Scaffolding System

● Key Features of the German Scaffolding System

● Regulations Governing Worker Safety

>> 1. TRBS 2121

>> 2. DIN Standards

>> 3. EN 13374

● How the German Scaffolding System Enhances Worker Safety

>> 1. Comprehensive Fall Protection

>> 2. Robust Structural Design

>> 3. Regular Inspections and Maintenance

>> 4. Training and Certification

>> 5. Use of Technology

● Best Practices for Ensuring Safety with the German Scaffolding System

● Conclusion

● FAQ

>> 1. What are the main features of the German scaffolding system?

>> 2. What regulations govern worker safety in Germany regarding scaffolding?

>> 3. How does the German scaffolding system prevent falls?

>> 4. What training is required for workers using scaffolds?

>> 5. How often should scaffolds be inspected?

● Citations:

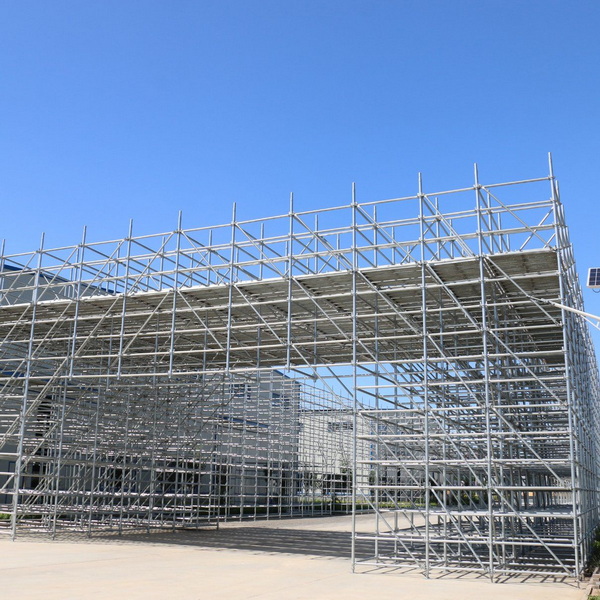

The German scaffolding system is renowned for its high safety standards and innovative design, making it a preferred choice in the construction industry. With a focus on protecting workers from falls and other hazards, this system incorporates various features that enhance safety while maintaining efficiency. This article explores how the German scaffolding system improves worker safety, examining its key components, regulations, and best practices.

Introduction to the German Scaffolding System

The German scaffolding system is characterized by its modular design, which allows for quick assembly and disassembly while providing robust support. It adheres to strict safety regulations set forth by organizations such as the German Institute for Standardization (DIN) and the European Committee for Standardization (CEN). These regulations ensure that scaffolding systems are designed and constructed to minimize risks associated with working at heights.

Key Features of the German Scaffolding System

1. Modular Design: The modular nature of the German scaffolding system allows for flexibility in construction. Components can be easily added or removed to accommodate different project requirements.

2. High Load Capacity: The system is engineered to support substantial loads, ensuring stability even under heavy usage.

3. Safety Features: Incorporation of guardrails, toe boards, and safety nets are standard in the German scaffolding system, providing multiple layers of protection against falls.

4. Quality Materials: The use of high-quality materials such as steel and aluminum enhances durability and strength, contributing to overall safety.

5. Compliance with Standards: The German scaffolding system complies with national and international safety standards, ensuring that it meets rigorous safety criteria.

Regulations Governing Worker Safety

The German scaffolding system operates under a comprehensive framework of regulations designed to protect workers. Key regulations include:

1. TRBS 2121

The Technical Rules for Industrial Safety (TRBS) 2121 outlines specific requirements for scaffolding operations. Key points include:

- Continuous protective devices must be installed at the top level during assembly.

- Access to scaffolding over 5 meters high should only be via stairs or lifts, not ladders.

- Trained personnel must check scaffold assembly and document functional checks directly on-site.

2. DIN Standards

The German Institute for Standardization (DIN) sets forth various standards that govern scaffold design and construction:

- DIN EN 12810/12811: These standards specify requirements for temporary works, including load capacities and structural integrity.

- DIN 4420: This standard provides guidelines for working scaffolds, emphasizing fall protection measures.

3. EN 13374

This European standard specifies requirements for temporary edge protection systems used in conjunction with scaffolding. It outlines criteria for performance testing and design to ensure worker safety.

How the German Scaffolding System Enhances Worker Safety

The implementation of the German scaffolding system incorporates several strategies aimed at enhancing worker safety:

1. Comprehensive Fall Protection

One of the primary concerns in construction is preventing falls from heights. The German scaffolding system addresses this through:

- Guardrails: Installed on all open sides of platforms at heights greater than one meter to prevent accidental falls.

- Toe Boards: These are placed along the edges of platforms to prevent tools or materials from falling off.

- Safety Nets: Used in conjunction with scaffolds to catch falling objects and protect workers below.

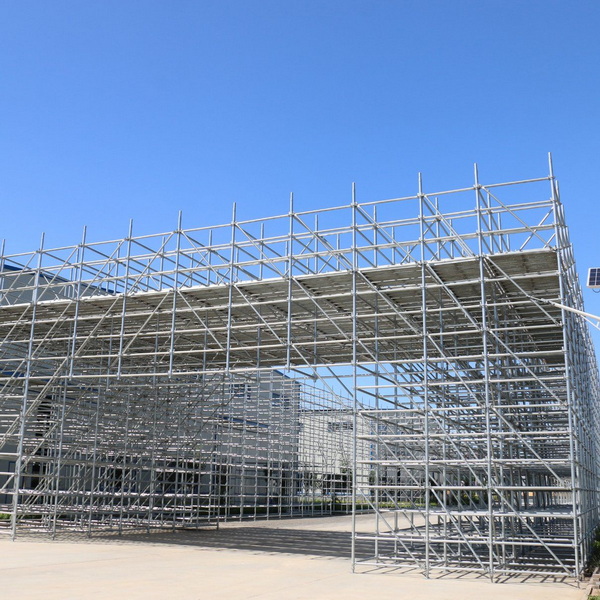

2. Robust Structural Design

The structural integrity of the scaffolding is crucial for worker safety:

- High Load Capacity: The design allows for heavy loads without compromising stability, reducing the risk of collapse.

- Stability Features: Diagonal braces and cross-bracing enhance lateral stability, ensuring that the scaffold remains secure during use.

3. Regular Inspections and Maintenance

Regular inspections are mandated by regulations to ensure ongoing safety:

- Daily Checks: Workers are required to inspect scaffolds before use each day to identify any potential hazards or damages.

- Maintenance Protocols: Scheduled maintenance ensures that all components are functioning correctly and safely.

4. Training and Certification

Proper training is essential for ensuring that workers understand how to use scaffolding safely:

- Scaffold User Training: Workers receive training on proper assembly, disassembly, and safe usage practices.

- Certification Requirements: Many regions require scaffolders to obtain certification demonstrating their knowledge of safety standards.

5. Use of Technology

Advancements in technology have also contributed to improving safety in scaffold operations:

- Digital Inspection Tools: Mobile applications allow workers to conduct inspections digitally, ensuring thorough documentation.

- Wearable Technology: Devices such as smart helmets can monitor worker movements and alert them to potential hazards in real-time.

Best Practices for Ensuring Safety with the German Scaffolding System

To maximize safety when using the German scaffolding system, contractors should adhere to best practices:

1. Conduct Thorough Training: Ensure all workers are trained in scaffold assembly and safe usage practices.

2. Implement Regular Inspections: Schedule daily inspections before use to identify any potential hazards.

3. Utilize Proper Equipment: Always use appropriate personal protective equipment (PPE), including helmets, harnesses, and non-slip footwear.

4. Follow Manufacturer Guidelines: Adhere strictly to manufacturer specifications regarding load limits and assembly instructions.

5. Encourage Communication: Foster an environment where workers feel comfortable reporting potential hazards or unsafe conditions.

Conclusion

The German scaffolding system significantly enhances worker safety through its robust design, adherence to strict regulations, comprehensive fall protection measures, regular inspections, and ongoing training initiatives. By prioritizing safety at every stage—from planning and assembly to daily operations—contractors can create a safer working environment that minimizes risks associated with working at heights.

As construction continues to evolve with new technologies and methods, maintaining a strong focus on worker safety will remain paramount. The lessons learned from implementing effective scaffolding systems will contribute not only to individual projects but also set a standard for best practices across the industry.

FAQ

1. What are the main features of the German scaffolding system?

The main features include modular design, high load capacity, comprehensive fall protection measures (guardrails, toe boards), quality materials, and compliance with strict regulations.

2. What regulations govern worker safety in Germany regarding scaffolding?

Key regulations include TRBS 2121 (Technical Rules for Industrial Safety), DIN EN 12810/12811 (temporary works standards), and EN 13374 (temporary edge protection systems).

3. How does the German scaffolding system prevent falls?

It prevents falls through guardrails installed at heights above one meter, toe boards along platform edges, and safety nets used below working areas.

4. What training is required for workers using scaffolds?

Workers must undergo training on proper scaffold assembly techniques, safe usage practices, inspection protocols, and emergency procedures related to scaffold operations.

5. How often should scaffolds be inspected?

Scaffolds should be inspected daily before use by trained personnel to ensure they are safe for operation.

Citations:

[1] https://www.ueg-eu.org/wp-content/uploads/2024/03/004-16_Practical-Guideline_RZ_2.pdf

[2] https://www.munk-group.com/en/products/scaffolding_c42840

[3] https://www.scafom-rux.com/en/scaffolding-blog/what-you-need-to-know-about-TRBS-2121

[4] https://www.dibt.de/en/construction-products-and-technniques/overview/productgroups/detail/construction-product/working-scaffolds-and-service-scaffolds

[5] https://www.albert-gerueste.de/en/

[6] https://www.youtube.com/watch?v=6MtrV2DJ_Pg

[7] https://layherna.com/scaffold-safety/

[8] https://www.peri.com/en/concrete-magazine/safety/safe-approach-to-quicker-results.html