Content Menu

● Introduction to the Qualcraft Ultra Jack Scaffolding System

>> Key Features of the Ultra Jack System

● Safety Features of the Qualcraft Ultra Jack Scaffolding System

>> 1. Guardrails and Toe Boards

>> 2. Stable Base Design

>> 3. Spring-Loaded Cam Lock Mechanism

>> 4. Field Replaceable Rubber Facing

● Proper Setup Procedures for Safety

>> 1. Site Preparation

>> 2. Assembly Instructions

● Best Practices for Safe Operation

>> 1. Limit Weight Capacity

>> 2. Use Personal Protective Equipment (PPE)

>> 3. Regular Inspections

>> 4. Training Requirements

● Maintenance Tips for Longevity and Safety

● Common Applications of the Qualcraft Ultra Jack Scaffolding System

● Conclusion

● FAQ

>> 1. What is the maximum height limit for using the Qualcraft Ultra Jack?

>> 2. How many workers can safely operate on an Ultra Jack platform?

>> 3. What materials are used in constructing the Ultra Jack?

>> 4. Are guardrails required when using the Ultra Jack system?

>> 5. How often should I inspect my Qualcraft Ultra Jack Scaffolding System?

● Citations:

The Qualcraft Ultra Jack Scaffolding System is a widely used solution in the construction industry, known for its efficiency and ease of use. However, safety remains a paramount concern when utilizing any scaffolding system. This article will explore the safety features, proper usage, and best practices associated with the Qualcraft Ultra Jack Scaffolding System. By understanding these aspects, workers can ensure a safer working environment while maximizing productivity.

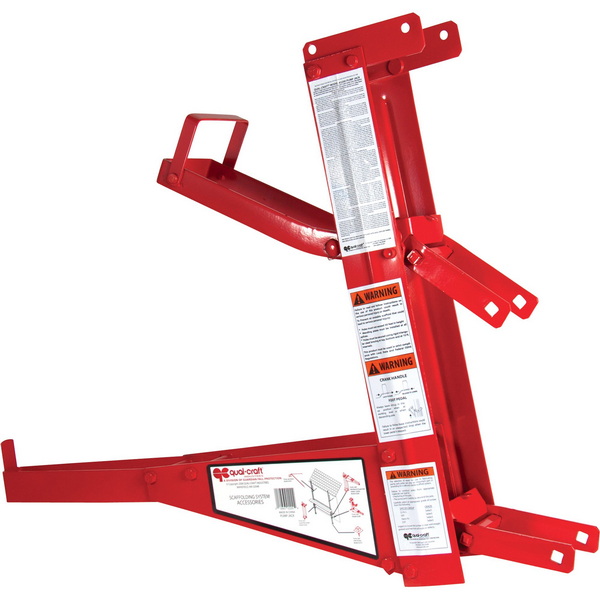

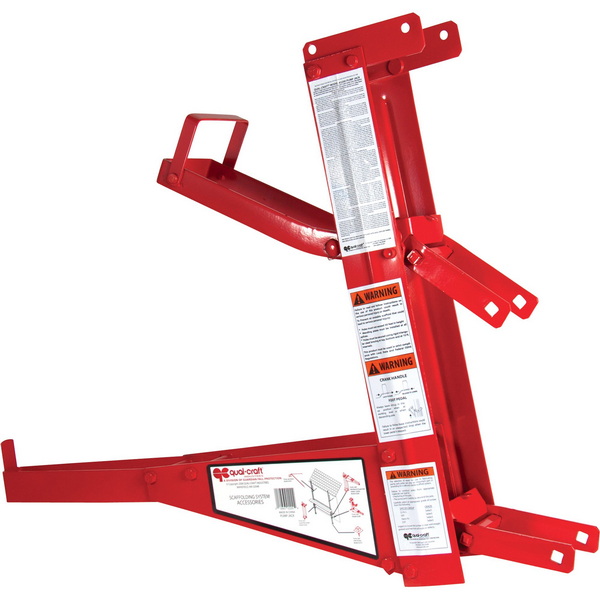

Introduction to the Qualcraft Ultra Jack Scaffolding System

The Qualcraft Ultra Jack Scaffolding System consists of a series of components designed for easy assembly and operation. This pump jack scaffolding system is particularly popular for tasks that require frequent height adjustments, such as siding installation, painting, and roofing. The system is built to support workers at various heights while maintaining stability and safety.

Key Features of the Ultra Jack System

1. Durable Construction: Made from reinforced aluminum with rubberized facing, the Ultra Jack poles offer superior strength and durability compared to traditional wooden poles.

2. Smooth Operation: The patented spring-loaded cam lock mechanism allows for smooth operation without clutches that can wear out over time.

3. Adjustable Platform Height: The platform can be adjusted from 14 inches to 24 inches, accommodating different working conditions and preferences.

4. Safety Accessories: The system can be equipped with guardrails, toe boards, and optional workbenches to enhance safety.

5. Lightweight and Portable: The design makes it easy to transport and set up on various job sites.

Safety Features of the Qualcraft Ultra Jack Scaffolding System

Safety is a critical aspect of any scaffolding system. The Qualcraft Ultra Jack incorporates several features aimed at protecting workers:

1. Guardrails and Toe Boards

The Ultra Jack system allows for the installation of guardrails and toe boards along the edges of the work platform. These components help prevent falls and keep tools or materials from slipping off the edge.

- Guardrails: Installed at both the top and mid-rail levels, guardrails provide an essential barrier against falls.

- Toe Boards: Positioned along the bottom edge of the platform, toe boards prevent tools and materials from falling onto workers below.

2. Stable Base Design

The Ultra Jack system features interchangeable bases that can be adapted to various ground conditions:

- Non-Skid Base: Ideal for flat surfaces, providing stability during use.

- Spiked Anchors: Designed for soft or uneven ground, ensuring secure footing for the scaffolding.

3. Spring-Loaded Cam Lock Mechanism

This mechanism not only enhances operational efficiency but also contributes to safety by preventing accidental lowering of the platform during use. The absence of a clutch means there are fewer moving parts that could fail or wear out over time.

4. Field Replaceable Rubber Facing

The rubber facing on the poles ensures a strong grip between the pole and pump jack, reducing slippage during operation. Regular inspections should be conducted to ensure this component is in good condition.

Proper Setup Procedures for Safety

To maximize safety while using the Qualcraft Ultra Jack Scaffolding System, proper setup procedures must be followed:

1. Site Preparation

Before setting up the scaffolding:

- Ensure that the ground is stable and level.

- Clear any debris or obstacles from the setup area.

- Identify potential hazards such as overhead power lines or unstable surfaces.

2. Assembly Instructions

Follow these steps to safely assemble the Ultra Jack system:

1. Position Vertical Poles: Place vertical poles at appropriate intervals based on your project needs.

2. Install Pump Jacks: Attach pump jacks securely to each pole at desired heights.

3. Add Work Platform: Place planks between pump jacks, ensuring they are level and securely fastened.

4. Install Safety Features: Add guardrails and toe boards as required by OSHA regulations.

5. Inspect All Components: Before use, inspect all parts for damage or wear.

Best Practices for Safe Operation

Once set up, following best practices during operation will further enhance safety:

1. Limit Weight Capacity

Adhere strictly to weight limits specified by manufacturers—typically no more than two workers or 500 pounds between any two poles—to prevent overloading.

2. Use Personal Protective Equipment (PPE)

Workers should always wear appropriate PPE when using scaffolding systems:

- Hard hats

- Safety glasses

- Harnesses (when working at height)

3. Regular Inspections

Conduct regular inspections before each use:

- Check all components for signs of wear or damage.

- Ensure that all safety features are in place and functioning correctly.

4. Training Requirements

Ensure all workers are trained in proper scaffold assembly, usage, and safety protocols as per OSHA regulations.

Maintenance Tips for Longevity and Safety

To ensure that your Qualcraft Ultra Jack Scaffolding System remains safe and functional over time:

1. Regular Cleaning: Clean all components regularly to remove dirt and debris that could lead to corrosion or malfunction.

2. Inspect Rubber Facing: Check the rubber facing on poles before each use; replace if worn or damaged.

3. Store Properly: Store components in a dry location away from direct sunlight when not in use to prevent deterioration.

Common Applications of the Qualcraft Ultra Jack Scaffolding System

The versatility of the Qualcraft Ultra Jack makes it suitable for various construction applications:

- Siding Installation: Ideal for accessing high areas safely while installing siding materials.

- Painting Projects: Provides stable platforms for painters working at elevated heights.

- Roofing Tasks: Allows roofers to work safely while providing easy access to different sections of a roof.

- General Construction Work: Useful for any task requiring elevation access without extensive setup time.

Conclusion

The Qualcraft Ultra Jack Scaffolding System offers a robust solution for construction professionals seeking safe access at varying heights. With its durable construction, innovative safety features, and ease of use, this system significantly enhances worker safety while maximizing productivity on job sites. By adhering to proper setup procedures, best practices during operation, and regular maintenance routines, users can ensure a safe working environment that meets OSHA standards.

FAQ

1. What is the maximum height limit for using the Qualcraft Ultra Jack?

The Qualcraft Ultra Jack should not be used above 48 feet off the ground as per manufacturer guidelines.

2. How many workers can safely operate on an Ultra Jack platform?

Typically, no more than two workers should occupy an Ultra Jack platform between any two poles to maintain safety limits.

3. What materials are used in constructing the Ultra Jack?

The system is primarily made from reinforced aluminum with rubberized facing for added grip and durability compared to traditional wooden scaffolds.

4. Are guardrails required when using the Ultra Jack system?

Yes, guardrails are required by OSHA regulations when using any scaffolding system including the Qualcraft Ultra Jack to ensure worker safety.

5. How often should I inspect my Qualcraft Ultra Jack Scaffolding System?

It's recommended to inspect your scaffolding before each use for signs of wear or damage, ensuring all components are functioning correctly.

Citations:

[1] https://images.thdstatic.com/catalog/pdfImages/1c/1c68edea-ac94-4a11-b724-e32db06e4ca0.pdf

[2] https://troweltrades.net/product/qual-craft-2000-ultra-jack-pump-jack/

[3] https://www.metaltech.co/product/aluminum-ultra-jack/

[4] https://www.ot.wustl.edu/FPtech/ultrajack.htm

[5] https://images.thdstatic.com/catalog/pdfImages/ac/ac827aef-001d-46af-b2fd-f2ecd2b39707.pdf

[6] https://www.metaltech.co/the-handy-solution-for-siding-and-painting/

[7] https://www.metaltech.co/download/METALTECH_Ultra-Jack_en.pdf

[8] https://www.northerntool.com/products/qualcraft-ultra-jack-scaffolding-system-adjustable-wall-brace-10ft-6in-11ft-6in-model-2620-189514