Content Menu

● Introduction to Aluminum Tube Scaffolding

● Benefits of Aluminum Tube Scaffolding

● Key Components of Aluminum Tube Scaffolding

● Installation Guide

● Choosing the Right Aluminum Tube Scaffolding

● Safety Considerations

● Maintenance and Storage

● Advanced Features and Accessories

● Environmental Considerations

● Cost Analysis

● Case Studies

● Conclusion

● FAQ

>> 1. What are the benefits of using aluminum tube scaffolding?

>> 2. How do I calculate the weight of an aluminum scaffold tube?

>> 3. Can I mix aluminum and steel tubes in the same scaffold?

>> 4. What safety features should I look for in aluminum tube scaffolding?

>> 5. How often should I inspect aluminum tube scaffolding?

● Citations:

Choosing the right aluminum tube scaffolding for your project is crucial for ensuring safety, efficiency, and cost-effectiveness. Aluminum scaffolding is popular due to its lightweight, corrosion-resistant properties, and ease of setup. Here's a comprehensive guide to help you select the best aluminum tube scaffolding for your needs.

Introduction to Aluminum Tube Scaffolding

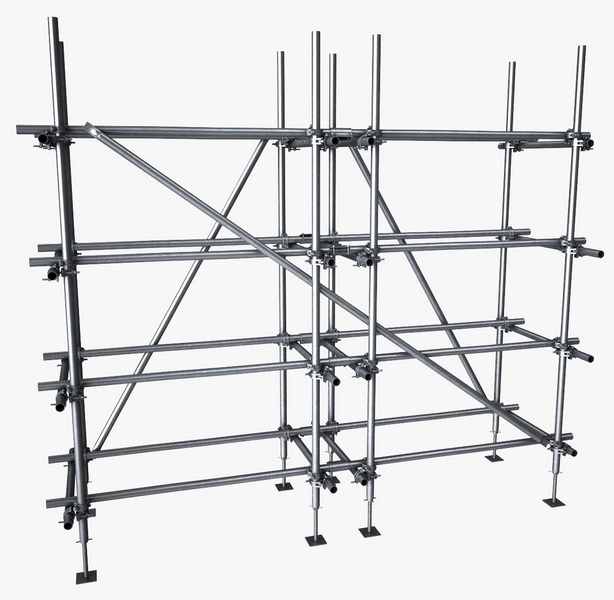

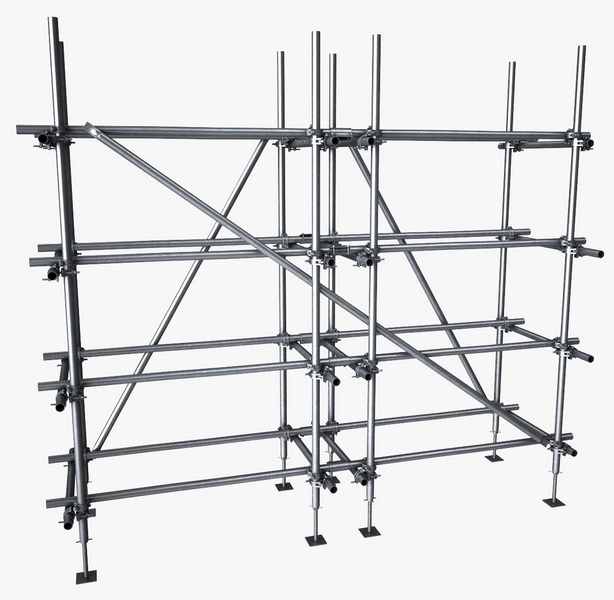

Aluminum tube scaffolding is widely used in construction, maintenance, and repair work due to its versatility and durability. It consists of aluminum tubes and frames that are connected to form a stable platform for workers to access heights safely.

Benefits of Aluminum Tube Scaffolding

1. Lightweight: Aluminum scaffolding is significantly lighter than steel scaffolding, making it easier to transport and assemble.

2. Corrosion Resistance: Aluminum is resistant to corrosion, which extends its lifespan and reduces maintenance costs.

3. Easy Setup: Aluminum scaffolding is generally quicker to set up and dismantle compared to other materials.

Key Components of Aluminum Tube Scaffolding

Understanding the components of aluminum tube scaffolding is essential for choosing the right system for your project.

- Base Frames: These are the foundation of the scaffold and provide stability.

- Horizontal Braces: These connect the base frames and provide additional stability.

- Diagonal Braces: These ensure the scaffold remains square and stable.

- Caster Wheels: Allow for easy movement of the scaffold.

- Platforms: Provide a safe working surface for workers.

- Guardrails: Essential for safety, preventing falls from the scaffold.

Installation Guide

Here's a step-by-step guide on how to set up aluminum tube scaffolding:

1. Prepare Components: Ensure all necessary parts are available, including base frames, horizontal and diagonal braces, caster wheels, ladders, platforms, and guardrails.

2. Assemble Base Frames: Insert caster wheels into the base frames and secure them.

3. Add Horizontal Braces: Lock these onto the frames to provide additional stability.

4. Install Diagonal Braces: These help square the scaffold and ensure stability.

5. Check Levels: Use a level to ensure the scaffold is perfectly horizontal.

6. Install Platforms: Place these at the desired working height.

7. Add Guardrails: Essential for safety, these prevent falls.

8. Final Check: Ensure all components are securely locked in place and the scaffold is stable.

Choosing the Right Aluminum Tube Scaffolding

When selecting aluminum tube scaffolding, consider the following factors:

1. Project Requirements: Determine the height and load capacity needed for your project.

2. Material Quality: Ensure the aluminum used is of high quality and resistant to corrosion.

3. Ease of Assembly: Opt for scaffolding with easy-to-use components that require minimal tools.

4. Safety Features: Look for scaffolding with built-in safety features such as guardrails and anti-slip surfaces.

5. Regulatory Compliance: Ensure the scaffolding meets local safety standards and regulations.

Safety Considerations

Safety is paramount when using aluminum tube scaffolding. Here are some key considerations:

1. Regular Inspections: Regularly inspect the scaffolding for damage or wear.

2. Proper Training: Ensure all users are trained in the safe assembly and use of the scaffolding.

3. Load Capacity: Never exceed the recommended load capacity of the scaffolding.

4. Stabilizers: Use stabilizers if the scaffold height exceeds three times the base width.

Maintenance and Storage

Proper maintenance and storage of aluminum tube scaffolding can extend its lifespan and ensure safety.

1. Cleanliness: Keep the scaffolding clean and free from debris.

2. Dry Storage: Store scaffolding in a dry area to prevent corrosion.

3. Regular Lubrication: Lubricate moving parts to ensure smooth operation.

Advanced Features and Accessories

Some advanced features and accessories can enhance the functionality and safety of aluminum tube scaffolding:

1. Adjustable Legs: Allow for leveling on uneven surfaces.

2. Safety Nets: Provide additional protection against falling objects.

3. Ladder Safety Gates: Prevent unauthorized access to the scaffold.

4. Scaffolding Ties: Secure the scaffold to the building for added stability.

Environmental Considerations

Aluminum tube scaffolding is generally more environmentally friendly than other materials due to its recyclability and durability. However, consider the following:

1. Recyclability: Aluminum is highly recyclable, reducing waste and environmental impact.

2. Energy Efficiency: Lightweight scaffolding requires less energy for transportation and setup.

Cost Analysis

While aluminum scaffolding may have a higher upfront cost, its long-term benefits can lead to cost savings:

1. Durability: Aluminum scaffolding lasts longer than other materials, reducing replacement costs.

2. Maintenance Costs: Lower maintenance needs due to corrosion resistance.

3. Efficiency: Faster setup and teardown times reduce labor costs.

Case Studies

Here are some examples of successful projects using aluminum tube scaffolding:

1. Construction Projects: Aluminum scaffolding was used in a high-rise building project for exterior facade work, providing safe access to all levels.

2. Maintenance Work: In a large industrial facility, aluminum scaffolding allowed for efficient maintenance of machinery without disrupting operations.

Conclusion

Choosing the right aluminum tube scaffolding for your project involves considering factors such as project requirements, material quality, ease of assembly, safety features, and regulatory compliance. By understanding these elements and following proper setup and safety guidelines, you can ensure a successful and safe project.

FAQ

1. What are the benefits of using aluminum tube scaffolding?

Aluminum tube scaffolding is lightweight, corrosion-resistant, and easy to set up, making it ideal for projects where mobility and efficiency are crucial.

2. How do I calculate the weight of an aluminum scaffold tube?

The weight of an aluminum scaffold tube can be calculated using the formula: Weight(KG) = 0.00879*wall thickness*(out diameter-wall thickness)*length(m).

3. Can I mix aluminum and steel tubes in the same scaffold?

No, it is not recommended to mix aluminum and steel tubes in the same scaffold due to differences in strength and durability.

4. What safety features should I look for in aluminum tube scaffolding?

Ensure the scaffolding includes guardrails, anti-slip surfaces, and stabilizers for added safety.

5. How often should I inspect aluminum tube scaffolding?

Regular inspections should be conducted before each use to check for damage or wear.

Citations:

[1] https://www.wm-scaffold.com/aluminium-scaffolding/

[2] https://www.youtube.com/watch?v=QOh_PasM77E

[3] https://max.book118.com/html/2017/0425/102172593.shtm

[4] https://www.safeworkaustralia.gov.au/system/files/documents/1703/guide-scaffolds-scaffolding.pdf

[5] https://www.youtube.com/watch?v=esCBQTr5vFs

[6] https://www.labour.gov.hk/eng/public/pdf/os/D/TOS_Guidance_notes_eng.pdf

[7] https://scaffoldtype.com/tubular-scaffolding/

[8] https://www.youtube.com/watch?v=A9TaJ0c38XA

[9] https://www.sohu.com/a/405881955_770312

[10] https://www.istockphoto.com/photos/aluminium-scaffolding

[11] https://www.istockphoto.com/photos/scaffolding-tube