Content Menu

● Introduction to Tube and Clamp Scaffolding

● Components of Tube and Clamp Scaffolding

● Safety Considerations for Assembly

>> Proper Assembly

>> Worker Training

>> Regular Inspections

>> Engineering Design

● Step-by-Step Assembly Guide

>> 1. Plan the Structure

>> 2. Prepare the Site

>> 3. Assemble the Base

>> 4. Install Vertical Posts

>> 5. Add Horizontal Members

>> 6. Install Bracing

>> 7. Secure the Scaffold

● Common Applications of Tube and Clamp Scaffolding

● Safety Equipment and PPE

● Training and Competency

● Regulations and Standards

● Conclusion

● FAQ

>> 1. What are the main components of tube and clamp scaffolding?

>> 2. Why is regular inspection important for tube and clamp scaffolding?

>> 3. What safety equipment is required when assembling tube and clamp scaffolding?

>> 4. How often should bracing be installed in tube and clamp scaffolding?

>>> 5. What are some common applications of tube and clamp scaffolding?

● Citations:

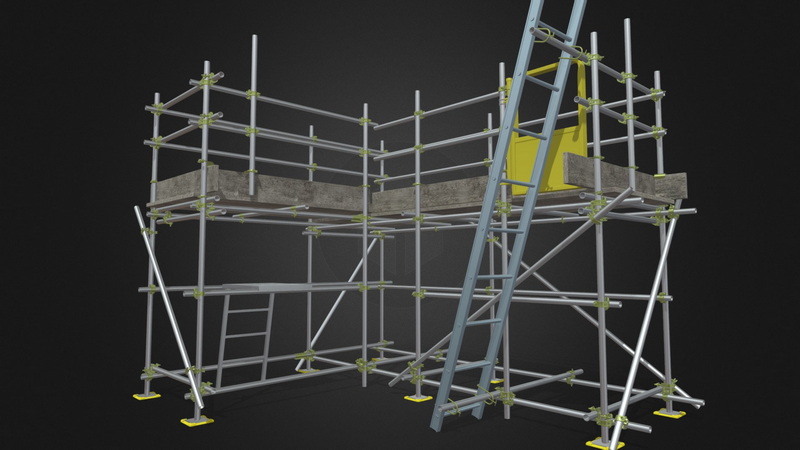

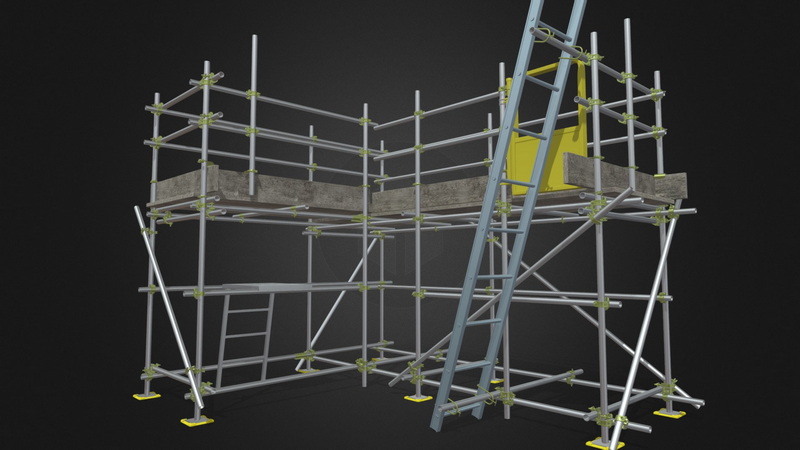

Tube and clamp scaffolding is a versatile and widely used system in the construction industry, known for its adaptability and strength. It consists of steel or aluminum tubes connected by various types of clamps, allowing for a wide range of configurations to suit different applications. This article will guide you through the safe assembly of tube and clamp scaffolding, highlighting key safety considerations and best practices.

Introduction to Tube and Clamp Scaffolding

Tube and clamp scaffolding is ideal for complex structures and irregular layouts due to its flexibility. The system includes three main components: steel tubes, clamps (or couplers), and base plates. The clamps are typically made of durable steel and come in several types, including right-angle clamps, swivel clamps, and sleeve clamps.

Components of Tube and Clamp Scaffolding

- Steel Tubes: These are the main structural elements, available in various lengths and materials such as galvanized steel or aluminum.

- Clamps: Right-angle clamps connect tubes at 90 degrees, swivel clamps connect at any angle, and sleeve clamps extend tube lengths.

- Base Plates: These provide stability and are essential for ensuring the scaffold's foundation is secure.

Safety Considerations for Assembly

Safety is paramount when assembling tube and clamp scaffolding. Here are some key considerations:

Proper Assembly

Ensuring that the scaffolding is correctly assembled and securely anchored is crucial to prevent collapse and ensure stability. This includes using high-quality materials and ensuring all connections are tightened properly.

Worker Training

Providing comprehensive training to workers on the safe use and assembly of the scaffolding is vital to prevent accidents and ensure proper handling.

Regular Inspections

Conducting regular inspections of the scaffolding to check for any signs of wear, damage, or instability is necessary to maintain safety standards.

Engineering Design

Ensuring that the scaffolding is properly designed and engineered to support the weight of workers and materials is critical to prevent overloading and structural failure.

Step-by-Step Assembly Guide

1. Plan the Structure

Before starting, draw an accurate sketch of the scaffolding structure, including all components such as platforms, cross braces, and anchor points.

2. Prepare the Site

Ensure the surface is firm, level, and capable of supporting the load. Use base plates and sills as necessary.

3. Assemble the Base

Place base plates centered on sills and ensure they are in firm contact with both sills and vertical posts.

4. Install Vertical Posts

Use right-angle clamps to secure vertical posts to the base.

5. Add Horizontal Members

Use right-angle clamps for horizontal members. Never use swivel clamps for this purpose.

6. Install Bracing

Face bracing should be installed from the bottom to the top of the scaffold on both faces. Vertical bracing should be installed across the width of the scaffold.

7. Secure the Scaffold

Ensure the scaffold is tied to the structure if necessary, especially if the height exceeds four times the minimum base dimension.

Common Applications of Tube and Clamp Scaffolding

Tube and clamp scaffolding is used in a variety of settings due to its adaptability:

- Construction Sites: For building, renovation, and maintenance projects.

- Industrial Settings: In refineries, petrochemical plants, and power plants.

- Temporary Structures: For building ramps, sheds, and stands.

Safety Equipment and PPE

When assembling and using tube and clamp scaffolding, it is essential to wear appropriate personal protective equipment (PPE), including:

- Hard Hats

- Safety Glasses

- Work Gloves

- Full Body Harness and Life Lines

Training and Competency

Ensuring that workers are properly trained and competent in the assembly and use of tube and clamp scaffolding is crucial. Training should cover:

- Erection and Dismantling

- Fall Protection

- Use of PPE

- Use of Tools and Equipment

Regulations and Standards

Compliance with local, state, and federal regulations is essential. This includes adhering to OSHA guidelines and relevant industry standards such as CSA standards for fall protection equipment.

Conclusion

Tube and clamp scaffolding offers versatility and strength, making it a preferred choice for complex construction projects. However, safety must always be the top priority. By following proper assembly procedures, ensuring worker training, and conducting regular inspections, you can minimize risks and ensure a safe working environment.

FAQ

1. What are the main components of tube and clamp scaffolding?

Tube and clamp scaffolding consists of steel or aluminum tubes, clamps (right-angle, swivel, and sleeve), and base plates.

2. Why is regular inspection important for tube and clamp scaffolding?

Regular inspections are crucial to identify any signs of wear, damage, or instability, ensuring the scaffolding remains safe for use.

3. What safety equipment is required when assembling tube and clamp scaffolding?

Essential safety equipment includes hard hats, safety glasses, work gloves, and full body harnesses with life lines.

4. How often should bracing be installed in tube and clamp scaffolding?

Bracing should be installed at regular intervals, typically every fifth bay for long scaffolds and every third set of posts vertically.

5. What are some common applications of tube and clamp scaffolding?

Common applications include construction sites, industrial settings like refineries and power plants, and temporary structures such as ramps and sheds.

Citations:

[1] https://www.youtube.com/watch?v=ZM6Tlh_NAnQ

[2] https://www.osha.gov/sites/default/files/publications/osha3150.pdf

[3] https://www.unitedscaffold.ca/scaffold-news/how-to-erect-tube-and-clamp-scaffolding/

[4] https://www.dir.ca.gov/dosh/dosh_publications/GuideForSupportedScaffolds.pdf

[5] https://cdn.dal.ca/content/dam/dalhousie/pdf/dept/facilities/FM%20Safety/fallprotection/Safe%20Job%20Procedure%20for%20Erecting%20Tube%20and%20Clamp%20and%20All%20Around%20Scaffolding%20June%202014.pdf

[6] https://www.saiaonline.org/files/COSP%20for%20Frame,%20System,%20Tube%20and%20Clamp,%20and%20Rolling%20Scaffolds.pdf

[7] https://brandsafway.com/uploads/files/orn401_bsl_tube_and_clamp_product_brochure.pdf

[8] http://www.ontario.ca/document/safety-guidelines-film-and-television-industry/guideline-no-23-scaffolding

[9] https://www.grinsulating.com/top-benefits-tube-and-clamp-scaffold/