Content Menu

● Understanding the 24 Foot Aluminum Walk Plank

>> Pre-Transport Inspection

>> Choosing the Right Vehicle

>> Driving Considerations

● Storing a 24 Foot Aluminum Walk Plank

>> Ideal Storage Conditions

>> Handling During Storage

>> Maintenance During Storage

● Safety and Compliance

>> Load Ratings and Support

>> Regulatory Guidelines

>> Worker Training

● Tips for Longevity and Efficiency

>> Protecting Your Investment

>> Efficient Jobsite Management

>> Sustainability

● Common Mistakes to Avoid

● Advanced Storage and Transport Solutions

>> Custom Storage Racks

>> Specialized Transport Equipment

>> Weatherproofing and Long-Term Storage

● Environmental and Economic Impact

>> Aluminum Plank Sustainability

>> Cost-Benefit Analysis

● Conclusion

● FAQ

>> 1. How do I safely transport a 24 foot aluminum walk plank in a pickup truck?

>> 2. What's the best way to store a 24 foot aluminum walk plank to prevent damage?

>> 3. How often should I inspect my aluminum walk plank?

>> 4. Can I store other materials on top of my aluminum walk plank?

>> 5. What's the recommended support spacing for a 24 foot aluminum walk plank on scaffolding?

The 24 foot aluminum walk plank is a vital tool for professionals in construction, roofing, painting, and maintenance. Its long span, lightweight build, and high load capacity make it ideal for creating safe, stable elevated work platforms. However, due to its length and material, proper transport and storage are critical for safety, longevity, and efficiency. This comprehensive guide covers best practices, supported by expert advice, visual walkthroughs, and real-world tips.

Understanding the 24 Foot Aluminum Walk Plank

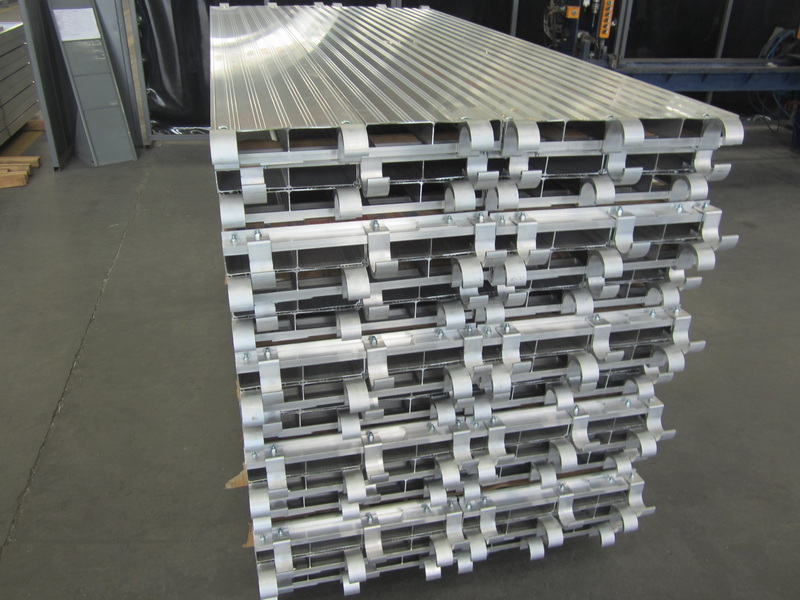

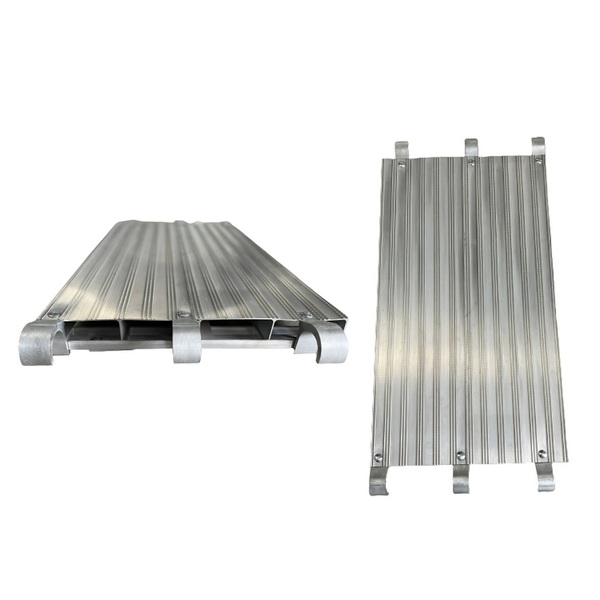

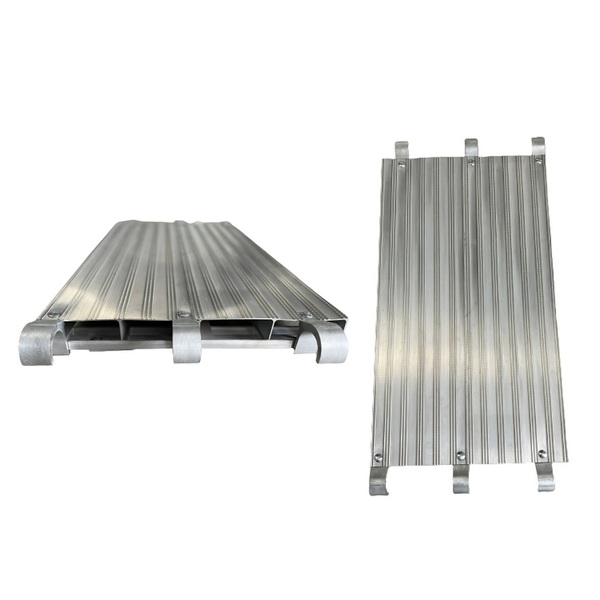

A 24 foot aluminum walk plank is typically 24 feet long and between 12–24 inches wide, constructed from high-grade aluminum alloy. It's designed for use with scaffolding, pump jacks, ladder jacks, and catwalks, supporting up to 500 lbs (two workers plus tools). Key features include:

- Lightweight: Easier to handle than steel or wood alternatives.

- Corrosion-resistant: Suitable for outdoor use in all weather.

- Slip-resistant surface: Ensures worker safety.

- End caps/handles: Protect edges and provide grip for carrying.

Pre-Transport Inspection

- Check for Damage: Inspect the plank for cracks, bends, or missing end caps. Never transport a damaged plank.

- Clean the Surface: Remove mud, oil, or debris to ensure safe handling.

Choosing the Right Vehicle

- Pickup Trucks: Most common for transporting long planks. The plank will overhang the bed, so secure it properly.

- Flatbed Trailers: Ideal for multiple planks or when transporting other long materials.

- Vans/Box Trucks: Only suitable if the interior length exceeds 24 feet, which is rare.

- Use Two People: A 24 foot aluminum walk plank is awkward for one person. Lift with your legs, keep your back straight, and carry the plank close to your body.

- Positioning: Place the plank flat in the truck bed or trailer, with at least 2 feet of plank inside the bed for stability.

- Overhang Safety: If the plank extends more than 4 feet beyond the vehicle, attach a red flag or warning device to the end (required by law in many areas).

- Strapping: Use at least two heavy-duty ratchet straps. Secure one at each end, running from one side of the bed, around/through the plank, to the other side. Add more straps if needed to prevent shifting.

“Attach it with 2 straps, going from the left side of the bed, through/around the plank, over to the right side. Add more straps if you want.” - Reddit Construction Advice

- Check for Movement: Try to move the plank by hand. If it shifts, tighten the straps or add more.

- Avoid Stacking Heavy Items: Do not place other materials on top of the plank during transport.

Driving Considerations

- Plan Your Route: Avoid low-clearance bridges, tight turns, and rough roads when possible.

- Drive Slowly: Take turns and bumps gently to avoid shifting the load.

- Check the Load: Stop periodically to ensure the plank remains secure.

Storing a 24 Foot Aluminum Walk Plank

Ideal Storage Conditions

- Dry, Covered Area: Store planks in a dry, sheltered space to prevent moisture exposure and UV damage.

- Ventilation: Ensure air can circulate around the plank to prevent condensation and corrosion.

- Avoid Direct Sunlight: Prolonged sun exposure can degrade surface treatments over time.

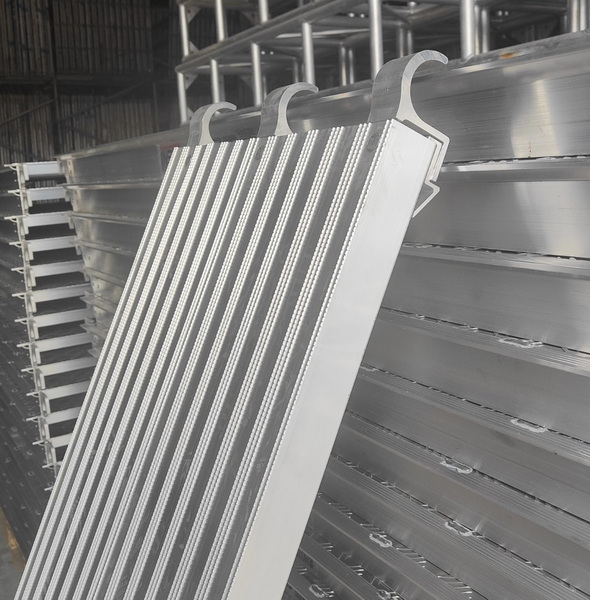

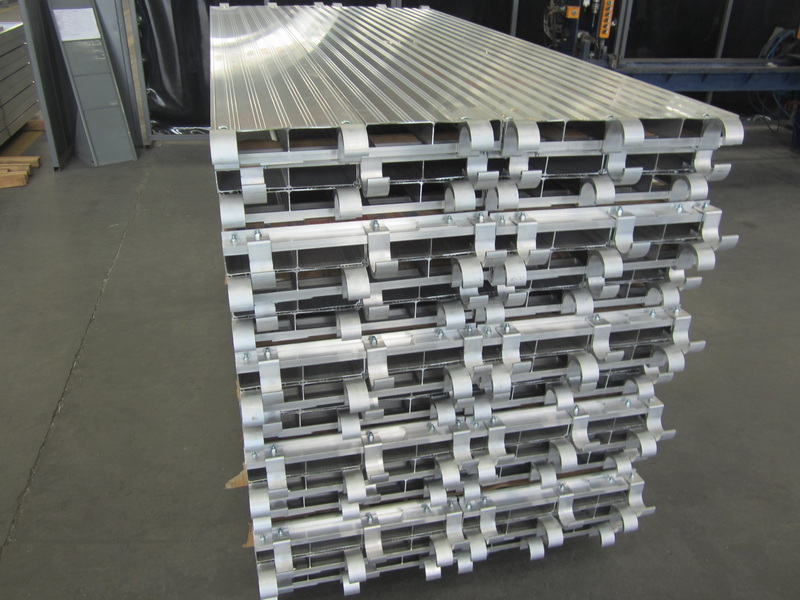

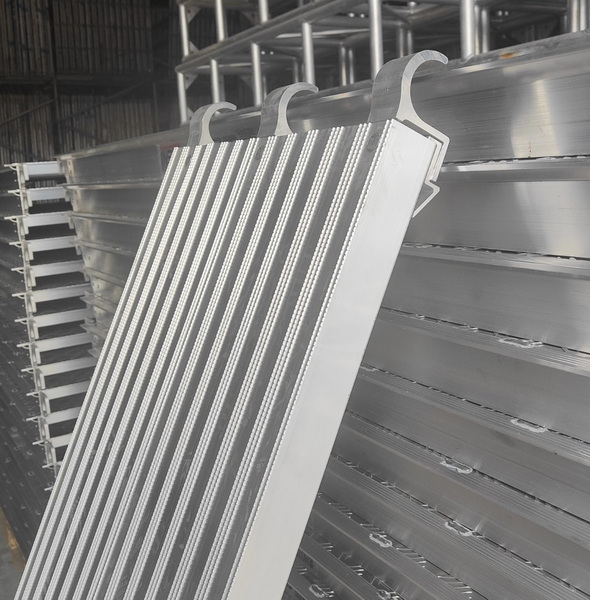

- Horizontal Stacking: Stack planks horizontally on a flat, level surface with spacers between each plank to promote air flow and prevent warping.

- Off-Ground Storage: Use pallets or racks to keep planks off the ground, avoiding contact with moisture or debris.

- Organized Storage: Arrange planks for easy access and quick inventory checks.

“Store planks in a dry, covered area to protect them from moisture and direct sunlight. Stack planks horizontally to prevent warping or bending.” - TP Scaffold Maintenance Guide

Handling During Storage

- Use Proper Lifting Techniques: Always lift with your legs, not your back. For long planks, use two people.

- Wear PPE: Gloves, steel-toe boots, and hard hats protect against injury during handling.

- Avoid Dropping: Never throw or drop a plank, as this can cause dents or cracks.

Maintenance During Storage

- Regular Inspections: Check for signs of corrosion, dents, or cracks before each use.

- Cleaning: Wipe down planks with a mild detergent and soft brush. Avoid harsh chemicals or abrasive cleaners.

- Surface Treatment: Apply anti-corrosion spray or protective coating as needed.

- Repair Minor Damage: Small dents can sometimes be repaired with epoxy resin, but replace planks with significant damage.

Safety and Compliance

Load Ratings and Support

- Never Exceed Capacity: Most 24 foot aluminum walk planks are rated for 500 lbs (two workers plus tools).

- Support Intervals: Place supports (scaffold frames, ladder jacks, etc.) at intervals recommended by the manufacturer-typically every 6–8 feet.

- Overhang: Allow at least 10 inches of overhang at each end, but never stand on unsupported overhang.

Regulatory Guidelines

- OSHA Compliance: Ensure the plank and setup meet OSHA 1926.451 and ANSI A10.8 standards for scaffolding.

- Inspection Records: Maintain logs of inspections and repairs for safety audits.

Worker Training

- Proper Handling: Train workers on safe lifting, carrying, and storage techniques.

- Hazard Recognition: Teach staff to identify and report damaged planks or unsafe storage conditions.

Tips for Longevity and Efficiency

Protecting Your Investment

- Avoid Excessive Heat or Chemicals: Exposure can weaken aluminum and compromise safety.

- Don't Store Items on Planks: Never use stored planks as makeshift shelves; this can cause warping or dents.

- Use Covers: In outdoor storage, use weatherproof covers to shield planks from rain and sun.

Efficient Jobsite Management

- Label Planks: Mark planks with company name or ID for easy tracking and theft prevention.

- Transport in Batches: When possible, move multiple planks together using racks or dollies designed for long materials.

- Plan Storage Near Work Area: Store planks as close as possible to the jobsite to reduce handling time.

Sustainability

- Recycling: Aluminum is fully recyclable. At end of life, recycle planks through appropriate channels.

- Regular Cleaning: Prevents buildup of materials that could cause corrosion or reduce grip.

Common Mistakes to Avoid

- Improper Strapping: Failing to secure the plank during transport can lead to accidents or loss.

- Storing on Uneven Ground: Causes bending or warping over time.

- Neglecting Inspection: Using damaged planks increases the risk of failure and injury.

- Overloading: Exceeding the weight limit can cause the plank to bend or break, risking collapse.

Advanced Storage and Transport Solutions

Custom Storage Racks

- Mobile Racks: Use wheeled storage racks for easy movement around large jobsites.

- Wall-Mounted Racks: For permanent storage in warehouses, wall-mounted racks save floor space and keep planks organized.

- Lockable Storage: Secure planks in lockable racks or cages to prevent theft on commercial jobsites.

Specialized Transport Equipment

- Material Handling Carts: For moving multiple planks at once, especially on large sites.

- Forklift Attachments: Use fork extensions or custom cradles to safely lift and move long planks.

- Crane Lifting: For high-rise projects, use certified lifting slings and spreader bars to hoist planks safely.

Weatherproofing and Long-Term Storage

- Shrink Wrapping: For seasonal storage, shrink-wrap planks to protect from dust and moisture.

- Desiccant Packs: Place moisture-absorbing packs in storage areas to prevent condensation and corrosion.

Environmental and Economic Impact

Aluminum Plank Sustainability

- Recyclability: Aluminum walk planks are 100% recyclable, reducing landfill waste.

- Long Lifespan: With proper care, a 24 foot aluminum walk plank can last 15–20 years, lowering replacement costs.

Cost-Benefit Analysis

| Factor | Aluminum Walk Plank | Wood Plank |

| Initial Cost | $400–$900 | $100–$250 |

| Lifespan | 15–20 years | 3–5 years |

| Maintenance | Low | Moderate |

| Recyclable | Yes | Limited |

Conclusion

Transporting and storing a 24 foot aluminum walk plank safely and efficiently is essential for maximizing its lifespan, ensuring worker safety, and maintaining compliance with industry standards. Always inspect planks before and after use, use proper lifting and securing techniques, and store them in dry, sheltered, and organized environments. Regular maintenance, staff training, and adherence to best practices will keep your aluminum walk planks in top condition, reduce replacement costs, and create a safer jobsite for everyone.

FAQ

1. How do I safely transport a 24 foot aluminum walk plank in a pickup truck?

Secure the plank with at least two heavy-duty ratchet straps, ensuring at least 2 feet of the plank is inside the bed. Attach a red flag to any overhang exceeding 4 feet and drive cautiously, checking the load periodically.

2. What's the best way to store a 24 foot aluminum walk plank to prevent damage?

Store planks horizontally on racks or pallets in a dry, covered area with spacers between layers for airflow. Keep them off the ground and out of direct sunlight to prevent warping and corrosion.

3. How often should I inspect my aluminum walk plank?

Inspect before each use and at least monthly during storage. Look for dents, cracks, corrosion, or missing end caps, and replace planks with significant damage immediately.

4. Can I store other materials on top of my aluminum walk plank?

No. Storing items on planks can cause warping or dents and may compromise the plank's structural integrity.

5. What's the recommended support spacing for a 24 foot aluminum walk plank on scaffolding?

Follow manufacturer guidelines, but generally, supports should be placed every 6–8 feet, with at least 10 inches of overhang at each end. Never stand on unsupported overhang.