Content Menu

● What Are Color Steel Sandwich Panels?

>> Key Features and Benefits

● Leading Color Steel Sandwich Panel Manufacturers and Suppliers in America

>> 1. Panel Sandwich Group USA

>> 2. FALK® USA

>> 3. Metl-Span

>> 6. Green Span Profiles

● Expanded Applications of Color Steel Sandwich Panels

>> Warehousing and Logistics

>> Cold Storage and Food Industry

>> Prefabricated and Modular Buildings

>> Commercial and Retail Spaces

>> Agricultural and Industrial Facilities

● Installation and Maintenance Tips

● Conclusion

● FAQ

>> 1. What are color steel sandwich panels used for?

>> 2. How do I choose between different manufacturers?

>> 3. Are these panels environmentally friendly?

>> 4. Can these panels be customized?

>> 5. What certifications should I look for?

Color steel sandwich panels are transforming the construction industry across America with their unmatched combination of durability, thermal insulation, aesthetic value, and installation efficiency. They have become a preferred material in various industries, including warehousing, logistics, commercial construction, and cold storage solutions. This article delves into the leading color steel sandwich panel manufacturers and suppliers in the American market, along with detailed insights into their products, applications, benefits, and answers to frequently asked questions.

What Are Color Steel Sandwich Panels?

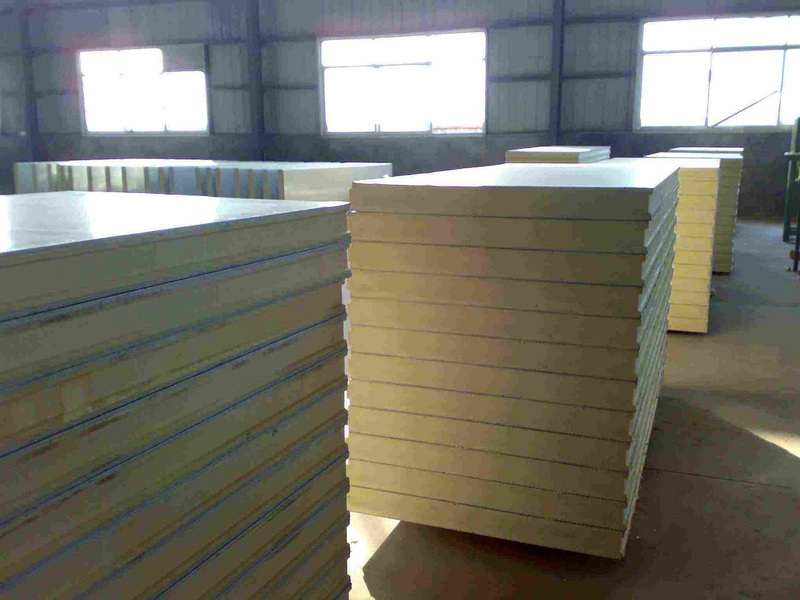

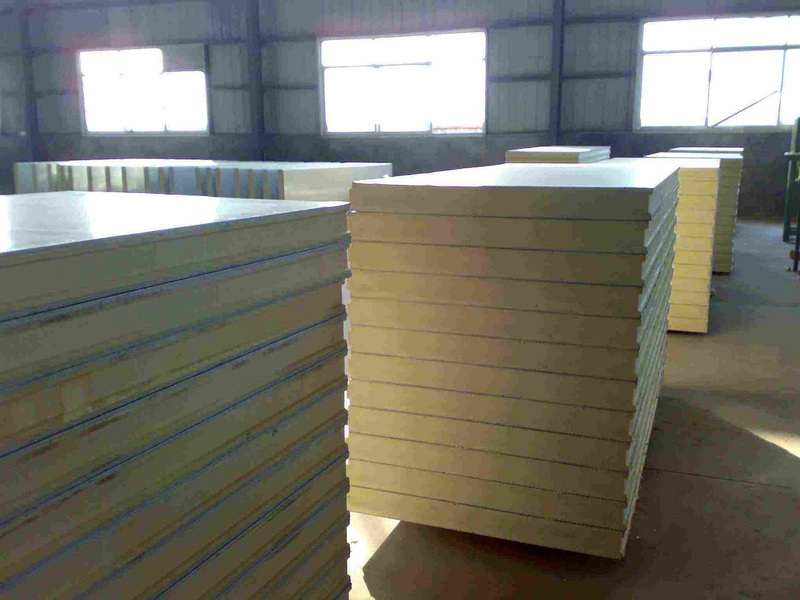

Color steel sandwich panels consist of two outer layers of colored steel sheets bonded to a core insulating material (such as polyurethane, PIR foam, or mineral wool). The color-added steel sheets provide an appealing finish while protecting the core, and the core provides excellent thermal and acoustic insulation. The sandwich construction results in a lightweight yet structurally strong panel which is resistant to weather, fire, water, and corrosion.

Key Features and Benefits

- High Thermal Insulation: Keeps indoor temperatures stable and reduces energy costs.

- Lightweight: Easier to handle and install than traditional construction materials.

- Fire Resistance: Many panels come with fire-retardant cores certified to withstand extreme conditions.

- Durability: Resistant to corrosion, impacts, and environmental stress.

- Wide Color Options: Ability to match architectural designs with a broad palette.

- Quick Installation: Panels can be prefabricated and quickly mounted onsite, speeding up construction schedules.

- Environmental Sustainability: Panels reduce overall building energy consumption and some manufacturers use recyclable materials.

These characteristics make color steel sandwich panels ideal for commercial buildings, industrial warehouses, cold storage, prefabricated homes, schools, and more.

Leading Color Steel Sandwich Panel Manufacturers and Suppliers in America

1. Panel Sandwich Group USA

The Panel Sandwich Group is known for providing a wide range of sandwich panels with specific applications in mind, from warehouses to cold rooms. Their panels typically feature high-density polyurethane cores (40 kg/m³), providing excellent thermal insulation and structural integrity.

What Sets Them Apart:

- Certified fire-resistant panels with up to 240 minutes of fire integrity.

- Various finishes and protective coatings tailored to client needs.

- A strong focus on custom design and technical support for efficient installation.

- Competitive pricing and robust logistics network for fast delivery across America.

Applications: Warehouses, factories, clean rooms, and refrigerated storage.

2. FALK® USA

FALK® has earned its position as a leader in manufacturing insulated metal panels (IMPs), serving both wall and roof applications. Their panels boast advanced technology allowing for increased thermal performance and durability.

Key Advantages:

- Production facilities located in North America ensure swift delivery and support.

- Comprehensive portfolio including panels designed for demanding environments like distribution centers and cold storage.

- Sustainable manufacturing techniques with an emphasis on improving building energy efficiency.

3. Metl-Span

Metl-Span is considered one of the largest producers of self-insulated metal panels in the Americas. Their product line spans from low-rise to high-rise buildings, offering adaptability for a variety of architectural projects.

Highlights:

- Extensive color range, panel profiles, and core insulation thicknesses.

- Proprietary technology that enhances connection strength and thermal barriers.

- Comprehensive technical and design assistance to streamline project development.

Unique Selling Points:

- Advanced coatings and finishes that resist weathering and fading.

- High-performance insulation cores contributing to energy conservation.

- Panels suited for both new construction and retrofit projects, offering design freedom.

Core Strengths:

- Wide selection of insulation cores technology including PIR foam for superior thermal resistance.

- Energy efficiency innovations that significantly reduce lifecycle carbon emissions.

- Diverse product lines suitable for every aspect of commercial and industrial building envelopes.

6. Green Span Profiles

Green Span Profiles is known for precise manufacturing and a strong commitment to quality, ensuring top-grade sandwich panels produced entirely in the USA. Their panels cater to a broad spectrum of applications from industrial to commercial sectors.

Key Features:

- State-of-the-art CNC machinery enables precision cutting, shaping, and finishing.

- Emphasis on quality control and customer-centered service.

- Panels that contribute to reduced operational costs by enhancing insulation and durability.

Expanded Applications of Color Steel Sandwich Panels

Warehousing and Logistics

In logistics centers and warehouses where temperature control and quick assembly are vital, color steel sandwich panels offer the perfect blend of insulation and structural strength. Their resistant surfaces stand up to heavy vehicle traffic and equipment.

Cold Storage and Food Industry

Cold chain maintenance is critical for food safety, and sandwich panels with polyurethane or PIR cores provide superior thermal barriers. Their moisture resistance prevents condensation, preserving product quality.

Prefabricated and Modular Buildings

Speed and efficiency define the prefabricated industry. Sandwich panels reduce build times significantly, enabling modular units and temporary or permanent structures that comply with building codes and reduce waste.

Commercial and Retail Spaces

Increasingly favored for retail facades and office walls, the panels allow vibrant color schemes and smooth finishes, enhancing aesthetic appeal while ensuring occupant comfort through insulation.

Agricultural and Industrial Facilities

These panels guard sensitive equipment and livestock environments by maintaining stable temperatures and protecting against harsh weather and chemical exposure.

Installation and Maintenance Tips

- Professional Installation: Though panels are designed for ease, correct installation ensures thermal efficiency and structural integrity. Look for manufacturers offering installation guides and technical support.

- Regular Inspection: Check for surface damage or loosening of fasteners periodically.

- Cleaning: Use mild detergents for surface cleaning to maintain the finish and prevent corrosion.

- Repair: Promptly address dents or penetrations to avoid water ingress or insulation degradation.

Conclusion

With their impressive blend of aesthetics, function, and efficiency, color steel sandwich panels have firmly secured their role in American construction. Choosing the right manufacturer or supplier depends on the specific needs of your project—including insulation requirements, design preferences, and delivery capabilities. Panel Sandwich Group, FALK®, Metl-Span, CENTRIA, Kingspan, and Green Span Profiles set the benchmark for quality, innovation, and customer service in this evolving market.

FAQ

1. What are color steel sandwich panels used for?

They are widely used in industrial buildings, warehouses, cold storage, prefabricated housing, commercial offices, and retail spaces because of their insulation, durability, and quick installation features.

2. How do I choose between different manufacturers?

Evaluate their panel quality, insulation values, fire resistance, color options, certifications, pricing, lead times, and customer support. Ensure they offer technical assistance and meet local building codes.

3. Are these panels environmentally friendly?

Many manufacturers prioritize eco-friendly production methods, use recyclable materials, and produce highly energy-efficient panels that help reduce building energy consumption.

4. Can these panels be customized?

Yes, most suppliers provide custom dimensions, color options, and profiles to match architectural and functional requirements.

5. What certifications should I look for?

Look for ASTM, FM, UL, and local compliance certifications regarding fire resistance, thermal performance, and wind loading to ensure safety and quality standards.