Content Menu

● Introduction to Color Steel Sandwich Panels

● Leading French Manufacturers of Color Steel Sandwich Panels

● Suppliers and Market Dynamics in France

● Applications and Benefits of Color Steel Sandwich Panels

● Sustainability in the French Color Steel Sandwich Panel Industry

● Innovations and Customization

● Role of OEM Services for International Brands

● Conclusion

● FAQ

>> 1. What insulation core materials are available in French color steel sandwich panels?

>> 2. How does the French market ensure panel quality and sustainability?

>> 3. What industries commonly use color steel sandwich panels in France?

>> 4. Are custom colors and finishes available?

>> 5. How do I choose a reliable manufacturer or supplier in France?

In the global construction industry, color steel sandwich panels have become an essential building material due to their excellent thermal insulation, durability, lightweight nature, and aesthetic appeal. For customers outside China seeking reliable OEM suppliers, France hosts a competitive market of top-quality color steel sandwich panel manufacturers and suppliers that combine advanced technology with environmentally friendly practices.

Introduction to Color Steel Sandwich Panels

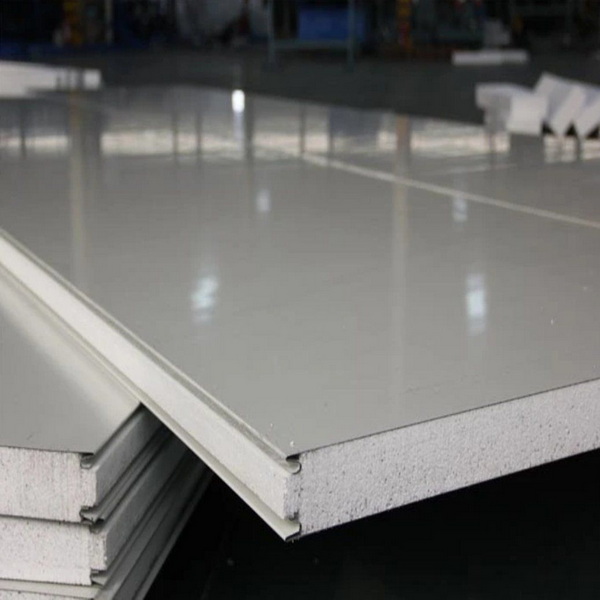

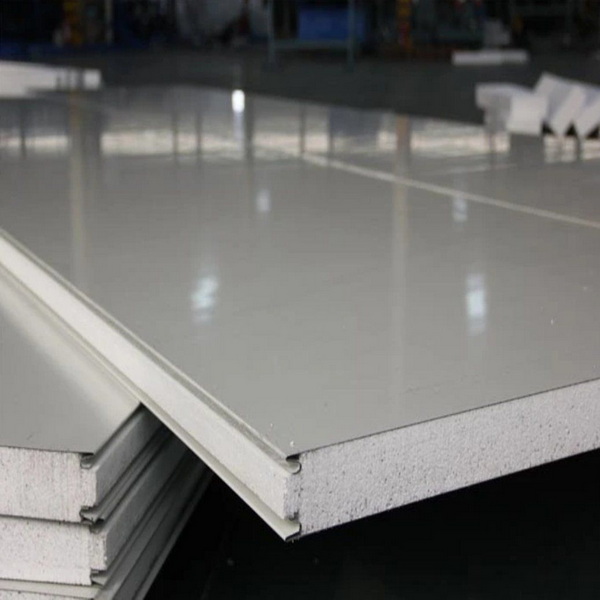

Color steel sandwich panels are composite panels consisting of two outer layers of pre-painted color steel sheets bonded to a core insulation material such as polyurethane (PUR), polyisocyanurate (PIR), expanded polystyrene (EPS), or mineral wool. These panels offer outstanding mechanical strength, weather resistance, fire resistance, and thermal insulation. They are widely used in commercial and industrial construction, cold storage facilities, warehouses, and cleanroom environments, where energy efficiency and operational performance are critical.

Leading French Manufacturers of Color Steel Sandwich Panels

France's manufacturing sector includes specialized companies producing high-quality color steel sandwich panels tailored to diverse building needs.

- Technological Advances: Modern French manufacturers utilize continuous production lines and advanced machinery to ensure precise lamination and bonding of steel facings to insulation cores, resulting in durable and high-performance panels. Some manufacturers incorporate low-carbon and recycled steel materials, aligning with global sustainability trends and reducing environmental impact.

- Material Options: Available cores include EPS for cost efficiency, PIR for enhanced fire retardance and thermal insulation, and mineral wool for superior fire resistance and soundproofing. Steel facings mostly use pre-painted galvanized sheets with customizable finishes aligned to RAL color systems, enabling a wide range of aesthetics to meet architectural requirements.

Suppliers and Market Dynamics in France

France's color steel sandwich panel market is vibrant and growing, driven by increasing construction and industrialization activities, especially in energy-efficient and green building sectors.

- The market size was valued at approximately USD 1.5 billion in 2024 and is forecasted to grow at a CAGR of 7.5% until 2033. This growth is fueled by government incentives for sustainable building materials, urban expansion, and a preference for fast installation solutions that reduce construction time and costs.

- Key suppliers not only serve domestic needs but also export to neighboring European countries and beyond. Their product portfolios emphasize thermal performance, ease of installation, durability, and compliance with rigorous European building codes, such as Eurocodes and fire safety regulations.

Applications and Benefits of Color Steel Sandwich Panels

- Energy Efficiency: These panels provide excellent insulation, minimizing heating and cooling costs in residential, commercial, and industrial buildings. Enhanced thermal insulation contributes to achieving green building certifications such as HQE (High Environmental Quality) and BREEAM, which are popular in France.

- Durability and Protection: Resistant to weather, corrosion, and fire, color steel sandwich panels ensure long service life while maintaining structural integrity. Their coatings protect against UV rays, moisture, and mechanical damage.

- Aesthetic Versatility: The variety of colors and surface finishes enables architects to achieve modern, attractive facades and interiors. Panels can be designed with smooth, embossed, or textured surfaces in a broad range of RAL or custom colors.

- Quick Installation: Lightweight and prefabricated nature significantly reduces construction time and labor costs. Panels can be easily transported and installed on site with minimal disruption, supporting fast-track construction projects.

Sustainability in the French Color Steel Sandwich Panel Industry

Sustainability is a growing priority in the construction sector globally and particularly in France. Color steel sandwich panel manufacturers in France are investing heavily in eco-friendly production processes, including:

- The use of recycled steel and post-consumer materials to reduce waste and lower carbon footprint.

- Employing energy-efficient manufacturing technologies, such as waste heat recovery and solar energy, to reduce resource consumption during production.

- Development of panels with enhanced thermal insulation, aimed at improving buildings' overall energy performance and reducing greenhouse gas emissions.

- Compliance with European Union regulations on building material environmental impact, such as REACH and the Construction Products Regulation (CPR). Many manufacturers provide Environmental Product Declarations (EPDs) to quantify their panels' sustainability credentials.

These sustainable practices not only meet the rising demands for green building materials but also improve the panels' life cycle performance, making French manufacturers attractive partners for international OEM collaborations.

Innovations and Customization

French manufacturers strive to enhance product performance and meet unique client specifications by incorporating various innovations:

- Fire-resistant Panels: Incorporating special mineral wool or other fire-resistant cores to meet stringent fire safety requirements in industrial and commercial settings.

- Acoustic Insulation: Panels engineered with cores and facings designed to reduce noise pollution, ideal for urban construction, hospitals, educational institutions, and facilities requiring sound control.

- Anti-corrosion Coatings: Specialized coatings protect panels used in harsh environments such as coastal regions, chemical plants, or places with high humidity.

- Surface Finishes and Textures: Beyond standard painted finishes, manufacturers offer embossed or textured surfaces, matte or glossy, that align with current architectural trends and client preferences.

- Panel Dimensions and Shapes: Customized lengths, thicknesses, and even curved panels are available to suit diverse and complex building designs, allowing flexibility in architectural expression.

- Integrated Functionalities: Some advanced panels include integrated vapor barriers, weather seals, or anti-condensation layers for enhanced building envelope performance.

Role of OEM Services for International Brands

As a Chinese factory offering OEM services for color steel sandwich panels to international brands, understanding the competitive French market helps optimize cooperation strategies. French manufacturers' focus on quality, compliance, and innovation sets high benchmarks. OEM suppliers can differentiate by:

- Offering highly customized panel solutions that meet or exceed European standards in thermal insulation, fire safety, and environmental compliance.

- Providing competitive pricing while maintaining premium quality assurance through rigorous quality control systems.

- Ensuring timely and reliable delivery schedules along with responsive after-sales technical support.

- Collaborating on co-engineering efforts and research to develop new panel configurations, coatings, or enhanced insulation properties tailored to client projects.

OEM partnerships benefit from the mutual exchange of technological expertise and market insights, resulting in product advancement and expanded business reach in Europe and globally.

Conclusion

France's color steel sandwich panel sector presents a robust and innovative manufacturing landscape, capitalizing on advanced production technologies and strong sustainability trends. As demand for energy-efficient, aesthetically versatile, and quickly installed building materials rises worldwide, French manufacturers and suppliers stand out as key players serving a broad market segment with high-quality OEM solutions. Leveraging local expertise and European regulatory standards, these companies offer a wide range of panels tailored to contemporary construction demands, making them ideal partners for international brands and wholesalers looking to source superior color steel sandwich panels.

OEM suppliers from other regions, including China, can benefit greatly by aligning their offerings with these standards and innovations, enabling successful collaboration and market expansion in France and the broader European market.

FAQ

1. What insulation core materials are available in French color steel sandwich panels?

French manufacturers offer insulating cores such as polyurethane (PUR), polyisocyanurate (PIR), expanded polystyrene (EPS), and mineral wool, each varying in thermal insulation, fire resistance, and cost.

2. How does the French market ensure panel quality and sustainability?

French suppliers adhere to strict European standards (EN norms) for material quality, thermal performance, and fire safety. Many manufacturers use recycled steel and low-carbon production technologies to reduce environmental impac.

3. What industries commonly use color steel sandwich panels in France?

They are widely used in industrial buildings, cold storage facilities, warehouses, commercial centers, and increasingly in energy-efficient residential construction.

4. Are custom colors and finishes available?

Yes, suppliers typically offer a broad spectrum of RAL colors and surface textures for both exterior and interior facings to meet architectural design requirements.

5. How do I choose a reliable manufacturer or supplier in France?

Look for certifications, years of industry experience, product warranty policies, technical support services, and compliance with building codes. Reputable suppliers often provide on-site installation assistance and post-sale customer service.