Content Menu

● Introduction to Color Steel Sandwich Panels

● Leading German Manufacturers and Suppliers

>> Schütte Aluminium and Steel Panels

>> ArcelorMittal

>> GETA GmbH

>> SAB Profiel

>> O-METALL GmbH

● Market Trends and Dynamics in Germany

● Applications and Advantages

>> Thermal Insulation and Energy Efficiency

>> Fire Resistance and Robustness

>> Design and Customization Options

>> Speed and Cost Effectiveness of Installation

● Sustainability and Green Building Initiatives

● Production Methods and Quality Control

● Conclusion

● FAQ

>> 1. What insulation cores are primarily used by German color steel sandwich panel manufacturers?

>> 2. Are customization options available for panel size, thickness, and colors?

>> 3. How is quality and regulatory compliance assured?

>> 4. What sustainability measures do German manufacturers employ?

>> 5. Which industries in Germany use color steel sandwich panels?

Germany is globally recognized for its engineering excellence and stringent construction standards. Among the materials that epitomize German innovation and performance are color steel sandwich panels highly sought after due to their excellent thermal insulation, structural durability, aesthetic versatility, and ease of installation. For foreign companies, wholesalers, and manufacturers particularly those offering OEM services from regions like China—understanding Germany's top color steel sandwich panel manufacturers and suppliers is crucial for meaningful market engagement and partnerships.

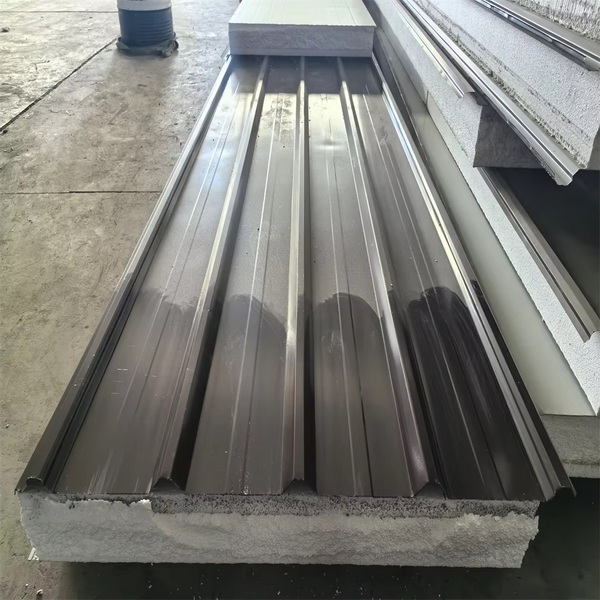

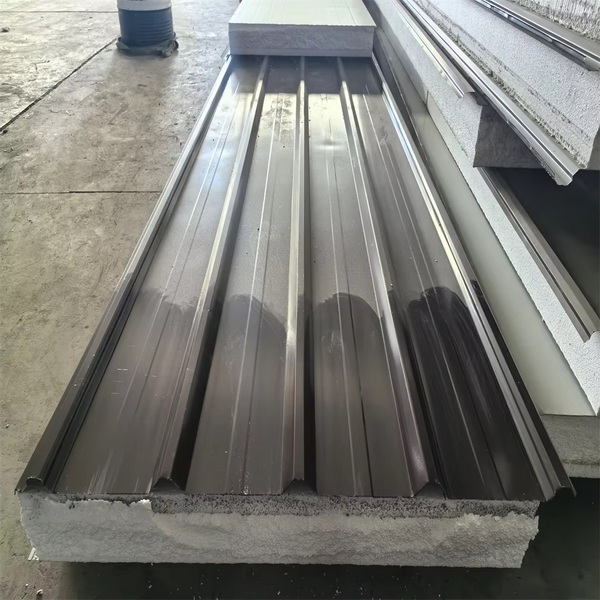

Introduction to Color Steel Sandwich Panels

Color steel sandwich panels are composite prefabricated building components consisting of two outer layers of pre-painted color steel sheets bonded to an insulating core. The insulation materials typically include polyurethane (PU), polyisocyanurate (PIR), mineral wool (stone wool), or phenolic foam. These cores offer a range of thermal insulating, fire-retardant, and acoustic benefits, meeting the rigorous performance expectations of modern building standards while supporting architectural design flexibility.

These panels are utilized extensively in industrial, commercial, residential, and agricultural projects, balancing lightweight construction with robustness, thermal efficiency, and an attractive finish. German manufacturers place particular emphasis on precision production, ecological sustainability, and adherence to rigorous EU regulations and local construction codes.

Leading German Manufacturers and Suppliers

Germany boasts an intense competitive market featuring manufacturers with decades of experience and a focus on high quality, sustainability, and technological prowess. Some of the market leaders include:

Schütte Aluminium and Steel Panels

With an established history, Schütte specializes in a wide variety of steel and aluminum facade and roofing products. Among their offerings, ISO wall panels with PUR foam or mineral wool cores stand out for their superior coating weights (25 µm internally and externally), surpassing typical market standards. Schütte's products cater to industrial, commercial, and agricultural facilities, providing multiple core thickness options and an extensive color range approved for demanding architectural projects.

ArcelorMittal

ArcelorMittal is an international steel powerhouse heavily influencing the German market. Their color steel sandwich panels leverage high-performance steel, such as the low-carbon XCarb® steel, combined with advanced insulation cores. These panels offer excellent energy efficiency, fire resistance, and mechanical strength. ArcelorMittal's emphasis on developing eco-friendly steel production is a hallmark of its sustainability leadership in the sector.

GETA GmbH

GETA GmbH delivers specialized sandwich panels catering both to the rail industry interiors and architectural applications. Located in southern Germany, GETA is known for bespoke fire-protected and insulating sandwich panel solutions, tailored to client specifications with an emphasis on quality and technical innovation.

SAB Profiel

Though headquartered in the Netherlands, SAB Profiel serves a sizeable German market portion by offering sandwich panels coated with Colorcoat HPS200 Ultra® and Colorcoat Prisma®—technologies known for outstanding corrosion resistance and durability. SAB's dedication to quality encompasses flexible color customization and panel profiles, making them a preferred choice for German industrial and commercial projects.

O-METALL GmbH

A strictly German manufacturer, O-METALL specializes in sandwich panels engineered for industrial and private construction applications. Their products consist of fully galvanized and color-coated steel or aluminum shells bonded to robust insulation cores, designed for long-lasting structural and thermal performance in Germany's diverse climatic conditions.

Market Trends and Dynamics in Germany

The German construction sector is deeply influenced by strong regulatory frameworks focusing on energy conservation, fire safety, and environmental sustainability. These factors have accelerated the adoption of:

- Insulation cores like PIR and mineral wool that meet demanding Energy Performance Certificates (EPC) and fire regulations (DIN 4102, EN 13501).

- Continuously improving coating technologies that offer advanced corrosion and UV resistance, essential for longevity.

- Automation investments in factory production to maintain quality while optimizing costs.

- Increased use of sandwich panels in modular construction, commercial logistics hubs, cold storage, public facilities, and agricultural projects.

Germany's commitment to green building drives manufacturers to issue Environmental Product Declarations (EPDs), publish lifecycle analyses, and contribute actively to circular economy principles.

Applications and Advantages

Thermal Insulation and Energy Efficiency

PU and PIR cores in German sandwich panels provide excellent insulation that drastically reduces heating and cooling energy demands, which benefits Germany's climate regulation efforts. Mineral wool also delivers sound insulation, critical in industrial and urban surrounding environments.

Fire Resistance and Robustness

Panels with mineral wool cores achieve high fire safety classification, meeting strict European fire regulations. Coated steel facings ensure resistance against corrosion, mechanical wear, and UV stress, securing structural integrity and appearance over decades.

Design and Customization Options

Manufacturers offer an extensive RAL color spectrum and textures—ranging from smooth metallic finishes to embossed or patterned surfaces—to satisfy diverse architectural requirements and enhance aesthetic appeal.

Speed and Cost Effectiveness of Installation

Prefabrication and light weight allow for rapid onsite assembly, significantly cutting labor costs and project timelines, a major consideration in Germany's highly competitive construction landscape.

Sustainability and Green Building Initiatives

German manufacturers lead in sustainable production, featuring:

- Low-carbon steel manufacturing methods like ArcelorMittal's XCarb® technology.

- Use of recycled raw materials and environmentally safe insulation cores low in VOCs and free from hazardous substances.

- Adherence to ISO 14001 environmental management standards.

- Production of sandwich panels designed for energy-efficient and green-certified buildings (DGNB, LEED, BREEAM).

- Incorporation of circular economy principles concerning resource usage and waste minimization.

Production Methods and Quality Control

Cutting-edge automated lines are common in Germany, employing coil coating, continuous lamination, and precision profiling technologies to ensure panel quality and uniformity at scale. Comprehensive testing regimes verify fire safety per EN 13501, thermal performance, mechanical strength, and coatings' durability. CE marking and ISO 9001 certification underscore the manufacturers' compliance and quality assurance.

Conclusion

Germany's color steel sandwich panel manufacturers demonstrate unrivaled expertise in precision engineering, quality assurance, and environmental stewardship. Their expansive customizable product ranges offer outstanding thermal, acoustic, and fire performances required by modern German building standards. International OEM partners, including Chinese scaffold material manufacturers, can capitalize on aligning to Germany's high standards and sustainable practices, unlocking valuable collaborations within one of Europe's most demanding construction materials markets.

FAQ

1. What insulation cores are primarily used by German color steel sandwich panel manufacturers?

Major cores include polyurethane (PU), polyisocyanurate (PIR), and mineral wool. PIR and mineral wool offer excellent fire resistance and insulation, favored in German construction.

2. Are customization options available for panel size, thickness, and colors?

Yes, customization is robust, with thicknesses available up to 300mm, flexible panel lengths, various profiles, and a wide range of RAL colors offered by suppliers.

3. How is quality and regulatory compliance assured?

Manufacturers adhere strictly to DIN and EN standards, ISO 9001 quality certification, and possess CE marking under EU construction products regulation. Panels undergo multifaceted testing including fire safety and thermal resistance.

4. What sustainability measures do German manufacturers employ?

Low-emission steel production, recycled materials, formaldehyde-free cores, environmental certifications like ISO 14001, and circular economy approaches are standard practices.

5. Which industries in Germany use color steel sandwich panels?

Applications span industrial buildings, warehouses, cold storage, agricultural facilities, commercial centers, and modular housing developments.