Content Menu

● Introduction to Color Steel Sandwich Panels

● Top Japanese Color Steel Sandwich Panel Manufacturers and Suppliers

>> 1. Nippon Steel Sheet Co., Ltd.

>> 3. IG KOGYO

>> 4. Ikeuchi Shoten

>> 5. BIMobject Japan Inc.

● Technological and Quality Features of Japanese Color Steel Sandwich Panels

● Applications of Color Steel Sandwich Panels in Japan and Globally

● Opportunities for Chinese OEM Manufacturers in Japan's Market

● Conclusion

● FAQ

>> 1. What materials are commonly used in Japanese color steel sandwich panels?

>> 2. How do Japanese panels achieve fire resistance standards?

>> 3. Can the size and thickness of panels be customized?

>> 4. What are the main applications of color steel sandwich panels in Japan?

>> 5. Are digital tools available to help select Japanese sandwich panels?

In today's global construction and manufacturing industries, color steel sandwich panels have become integral components for projects requiring a combination of strength, insulation, and aesthetic appeal. The demand for high-quality, durable, and energy-efficient building materials has led to significant advancements in sandwich panel technology. Japan, known for its technological innovation and rigorous quality standards, hosts some of the top color steel sandwich panels manufacturers and suppliers worldwide. This article provides an in-depth look at the leading Japanese manufacturers, their product features, technological innovations, and market applications. For Chinese scaffolding material manufacturers offering OEM services to foreign brands, understanding these key players and their offerings is essential for successful international collaboration and competitive positioning.

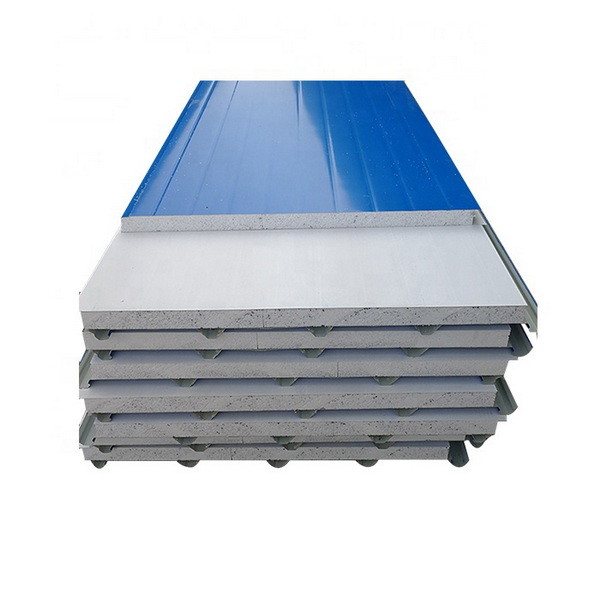

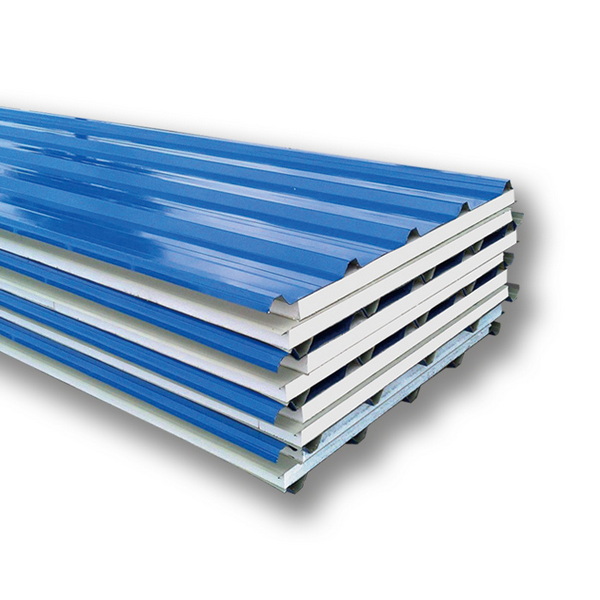

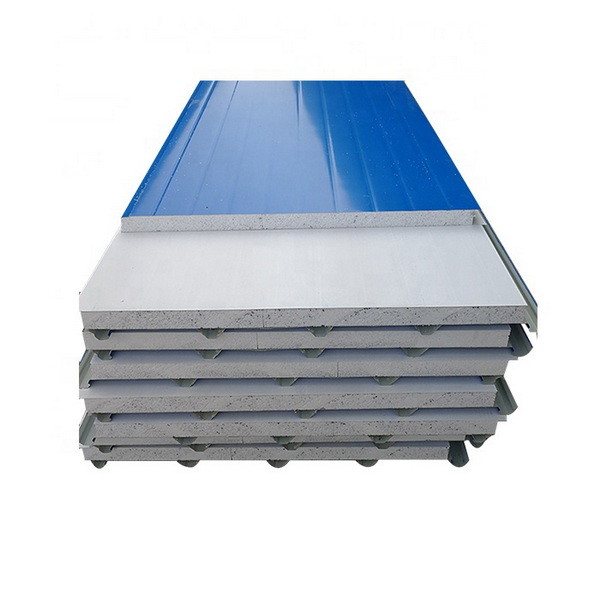

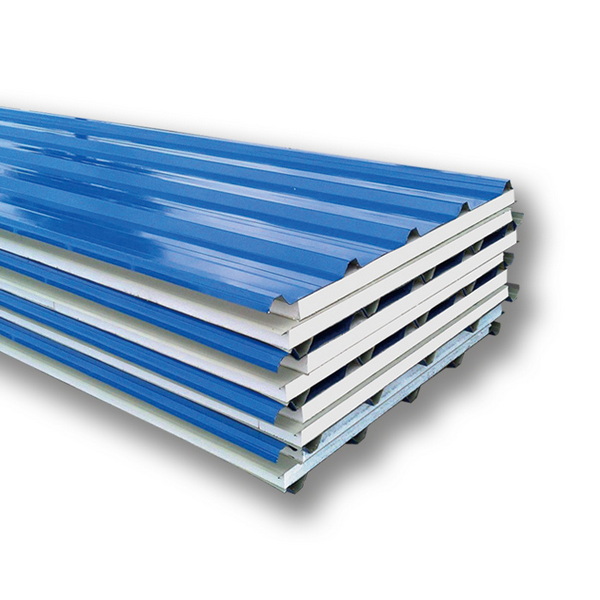

Introduction to Color Steel Sandwich Panels

Color steel sandwich panels are composite materials consisting of an insulating core enclosed between two sheets of color-coated steel. The outer steel layers provide structural integrity, corrosion resistance, and visual appeal, while the inner core contributes thermal insulation and fire resistance. The core can be made from various materials, including polyisocyanurate foam (PIR), polyurethane foam (PU), rock wool, and expanded polystyrene (EPS). The choice of core depends on the application's thermal, acoustic, and fire safety needs.

The steel facings are coated with durable polyester or fluoropolymer paints in various color options, providing both protection against the elements and aesthetic versatility. These panels are widely used in industrial buildings, commercial complexes, refrigerated facilities, clean rooms, and prefabricated structures, where quick installation combined with durability is critical.

Top Japanese Color Steel Sandwich Panel Manufacturers and Suppliers

Japan's color steel sandwich panel market is led by a blend of longstanding manufacturers with extensive expertise and innovative newcomers focusing on eco-friendly materials and digital integration.

1. Nippon Steel Sheet Co., Ltd.

Nippon Steel Sheet, a subsidiary of the Nippon Steel Group, is a pioneer in metal insulation sandwich panels with their flagship brand, NISC. Their panels stand out for advanced heat insulation and fire resistance, incorporating PIR foam and rock wool cores encased within high-quality steel sheets coated with weather- and corrosion-resistant polyester or fluorine resin.

The ISOWAND series, part of their product lineup, includes “FIREPROOF ISOWAND PRO” panels that use mineral wool cores offering exceptional fire protection capabilities. These panels are certified by Japan's Ministry of Land, Infrastructure, Transport and Tourism, carrying ratings for fire resistance (NM-4431) and seismic toughness, highly relevant for Japan's earthquake-prone environment. Panel thicknesses vary from 25mm to 75mm, widths of 600mm or 900mm, and customizable lengths available up to 9 meters. Nippon Steel also emphasizes eco-efficiency, with production processes minimizing environmental impact.

Nikkei Panel System, established in 1961, specializes in non-combustible sandwich panels such as their Woldan® brand. Their panels use PIR foam cores and Galvalume steel plates coated with polyester resin for enhanced durability and corrosion resistance. Nikkei panels are widely used in clean rooms, food processing plants, cold storage warehouses, and other specialized industrial applications that demand stringent thermal and fire safety standards.

Panels are offered in standard thicknesses of 35mm and 50mm, with excellent heat insulation properties. The company also invests considerably in R&D to improve environmental friendliness by introducing recyclable panel options and improving the lifecycle impact of their products.

3. IG KOGYO

IG KOGYO brings more than 50 years of experience producing metal exterior wall materials and sandwich panels. Their product line, including the SP Garbou series, is well-known for its superior corrosion resistance provided by a magnesium-rich plating and 150g/m² plating weight on steel facings.

IG KOGYO offers various aesthetic and functional style series such as Simple Modern, Natural, and Basic to meet current architectural trends in Japan. They also provide custom color orders and panel designs, allowing architects and contractors greater flexibility to integrate panels into diverse building projects.

4. Ikeuchi Shoten

Ikeuchi Shoten has established itself as a supplier of energy-efficient metal insulation sandwich panels since the mid-20th century. Their panels, certified with the NM-3065 standard for non-combustibility and one-hour fire resistance, are featured in a wide range of construction projects with an emphasis on fire safety.

Customization is a key component of Ikeuchi Shoten's service, enabling clients to order panels in thicknesses from 30mm up to 75mm with a broad palette of colors to blend both function and design aesthetics seamlessly.

5. BIMobject Japan Inc.

Though not a traditional panel manufacturer, BIMobject Japan plays a vital role as a digital platform retailer and supplier. Founded in 2017, they provide architects, engineers, and clients easy access to BIM (Building Information Modeling) files from over 2,000 manufacturers worldwide, including many leading Japanese sandwich panel producers.

Their platform supports detailed digital selection, specification comparisons, and access to certifications, accelerating project planning and procurement cycles while ensuring compliance with Japanese building codes and standards.

Technological and Quality Features of Japanese Color Steel Sandwich Panels

Japanese manufacturers integrate multiple advanced features into their sandwich panels to meet the diverse demands of the construction and manufacturing sectors:

- Outstanding Thermal Insulation: The use of PIR foam and rock wool cores ensures low thermal conductivity, significantly reducing heating and cooling energy requirements in buildings.

- Fire Resistance: Panels utilize mineral cores (rock wool) and flame-retardant foam formulations to meet rigorous fire safety tests. Certifications like NM-4431 and NM-2821 attest to their performance.

- Earthquake and Structural Resilience: Japan's seismic activity necessitates panels designed to endure heavy tremors without compromising structural stability. These panels are tested to withstand earthquake forces.

- Corrosion and Weather Resistance: Advanced coatings like fluorine resin maintain steel surface integrity against humidity, acid rain, and other corrosive effects.

- Customizable Dimensions and Colors: Panels can be manufactured to specific thicknesses, widths, and appearances. This flexibility supports architectural creativity and adapts to project-specific requirements.

- Environmental Considerations: Many manufacturers incorporate recyclable materials and environmentally friendly coatings, reflecting a global shift toward sustainable construction.

Applications of Color Steel Sandwich Panels in Japan and Globally

Color steel sandwich panels from Japan are utilized in numerous applications, offering functional benefits paired with aesthetic value:

- Industrial and Warehouse Buildings: Panels provide durable walls and roofing with efficient insulation to protect goods and machinery.

- Clean Rooms and Laboratories: The hygienic and fire-resistant nature of these panels supports controlled environments necessary for pharmaceuticals and electronics manufacturing.

- Commercial and Office Buildings: Panels serve as exterior facades combining design flexibility with enhanced thermal performance.

- Prefabricated and Modular Housing: Lightweight and quick to install panels reduce construction time while maintaining durability.

- Cold Storage and Refrigeration: Excellent insulation properties maintain consistent cold temperatures essential for food storage and pharmaceuticals.

Opportunities for Chinese OEM Manufacturers in Japan's Market

As a Chinese scaffolding material manufacturer offering OEM services to export brands and wholesalers, understanding Japan's color steel sandwich panel market is invaluable. Japanese manufacturers and suppliers emphasize product quality, certification compliance, and customization. To succeed as an OEM partner, factories must meet these criteria by adopting similar standards and technologies.

Collaboration can take many forms, from supplying raw materials or semi-finished panels under OEM contracts to co-developing specialized products. Leveraging Japanese digital platforms such as BIMobject can facilitate market entry by matching products with architectural and engineering specifications in real-time.

Furthermore, Chinese manufacturers can use insights into Japanese market preferences—such as the demand for seismic-resistant and fireproof panels—to innovate and broaden their product range for global competitiveness.

Conclusion

Japan's top color steel sandwich panel manufacturers and suppliers are recognized for their technological innovation, rigorous quality control, and versatile product ranges. Companies like Nippon Steel Sheet, Nikkei Panel System, IG KOGYO, and Ikeuchi Shoten exemplify superior fire resistance, thermal insulation, and seismic resilience in their panels – qualities essential to Japan's demanding construction environment. For Chinese manufacturers involved in OEM services to foreign brands, gaining insight into these manufacturers' technologies and market approaches offers a valuable roadmap for expanding into Japan and other global markets. By focusing on customization, certification, and sustainability, manufacturers can align with international standards, creating strong partnerships and enhancing their competitive advantage.

FAQ

1. What materials are commonly used in Japanese color steel sandwich panels?

Japanese manufacturers commonly use polyisocyanurate foam (PIR), polyurethane foam (PU), mineral wool (rock wool), and expanded polystyrene (EPS) as core materials, combined with high-quality color-coated steel sheets.

2. How do Japanese panels achieve fire resistance standards?

By using fireproof cores such as rock wool and flame-retardant PIR/PU foams along with certified coating layers, Japanese sandwich panels meet strict fire safety certifications under Japan's NM-4431 and NM-2821 standards.

3. Can the size and thickness of panels be customized?

Yes. Thickness options typically range from 25mm to 75mm, with panel widths between 600mm and 1000mm, and lengths customizable up to 9 meters or more according to client requirements.

4. What are the main applications of color steel sandwich panels in Japan?

They are best suited for industrial buildings, refrigerated warehouses, clean rooms, commercial facades, modular housing, and environments requiring stringent fire and thermal safety.

5. Are digital tools available to help select Japanese sandwich panels?

Yes, digital platforms such as BIMobject Japan provide detailed catalogs with BIM data and certifications, facilitating specification-based selections for architects and contractors.