Content Menu

● What Are Color Steel Sandwich Panels?

● Top Color Steel Sandwich Panel Manufacturers and Suppliers in Korea

>> 1. SY Panel (SY Group)

>> 2. Sae-Rom Panel Co., Ltd.

● Technology and Quality of Korean Color Steel Sandwich Panels

>> Advanced Material Technologies

● Applications for Korean Color Steel Sandwich Panels

● Conclusion

● FAQ

>> 1. What core materials are most common in Korean color steel sandwich panels?

>> 2. How do these panels meet fire safety regulations?

>> 3. Are Korean sandwich panels customizable?

>> 4. Can they be used for cold rooms or refrigeration?

>> 5. What advantages do Korean suppliers provide internationally?

In the modern construction materials industry, Color Steel Sandwich Panels have become vital components that deliver both structural efficiency and high thermal insulation. With rapid urbanization, increasingly stringent building regulations, and demands for energy-efficient and fire-resistant materials, Korea has emerged as a leader in the production and export of color steel sandwich panels. For Chinese scaffolding material manufacturers providing OEM services to foreign brands, wholesalers, and manufacturers, understanding the key players, technological benchmarks, and market dynamics in Korea's sandwich panel industry is essential for strategic business growth.This article provides an overview of Korea's top Color Steel Sandwich Panel manufacturers and suppliers like SY Panel, Sae-Rom Panel, KINDUS, and Baikal.

What Are Color Steel Sandwich Panels?

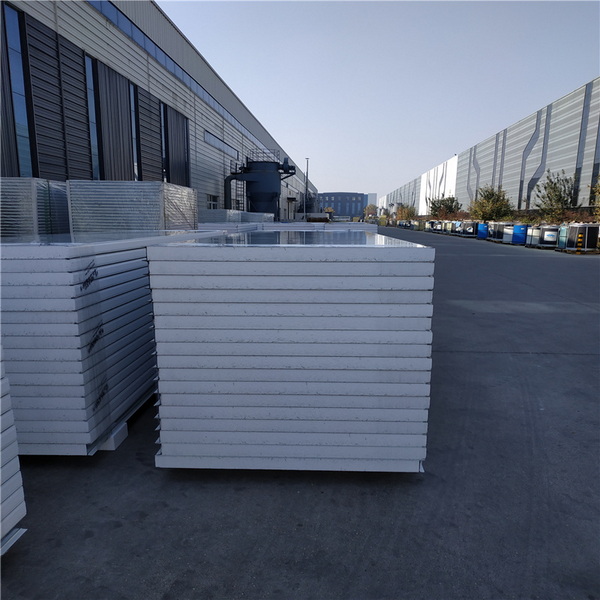

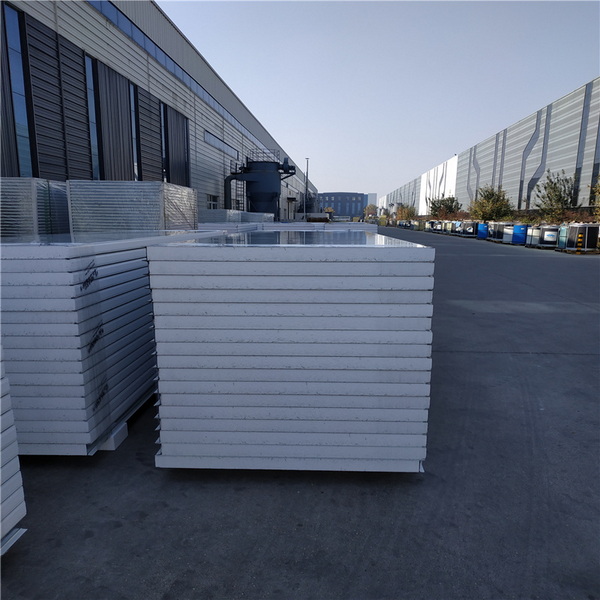

Color Steel Sandwich Panels are engineered composite panels composed of an insulating core material sandwiched between two color-coated steel sheets. These panels combine the mechanical strength, weather resistance, and visual appeal of steel with the thermal and acoustic insulating properties of the core. Common insulation materials include polyurethane foam (PU/PUR), expanded polystyrene (EPS), and mineral or rock wool.

The outer steel sheets are coated with durable painting systems (polyester, fluorine, or PVDF coatings) that protect against corrosion and UV damage, while offering diverse aesthetic options. This combination results in panels that are lightweight, energy-efficient, fire-safe, and quick to install, making them ideal for a wide range of buildings—from industrial warehouses and cold storage units to commercial facades and modular constructions.

Top Color Steel Sandwich Panel Manufacturers and Suppliers in Korea

1. SY Panel (SY Group)

SY Panel is among Korea's most acclaimed color steel sandwich panel manufacturers and suppliers, offering a wide product range including EPS, fire-retardant panels, glass wool, and urethane core varieties for external and internal applications. Their panels are widely deployed in industrial factories, commercial spaces, cold storage facilities, and prefabricated housing.

Their focus on quality control, innovation, and customer service makes SY Panel a trusted partner for domestic and international projects. Their production is supported by advanced automation and includes on-demand customization for thickness, width, and color options.

2. Sae-Rom Panel Co., Ltd.

Since 2004, Sae-Rom Panel has specialized in manufacturing and exporting fabricated color steel sandwich panels worldwide. Their comprehensive product lineup includes EPS, non-flammable EPS, glass wool, and rock wool sandwich panels, alongside corrugated steel sheets, doors, windows, and accessories.

- Operating manufacturing facilities in Gyeonggi-do and Hwaseong, Sae-Rom provides flexible customization options and a broad color spectrum, catering to various climates and architectural needs globally. Their panels are renowned for durability, insulation performance, and compliance with fire safety standards.

- KINDUS is a prominent Korean specialist in sandwich panel production and finished solutions. Their product range covers roof, wall, and cold room panels with PUR, PIR, and mineral wool cores targeting domestic and export markets.

- KINDUS also manufactures panel production lines, offering equipment for mass customization and innovation in core materials for enhanced fire resistance and insulation. Their focus on technology makes them a key player in Korea's sandwich panel industry.

- Baikal Panel is a prominent supplier in Korea with expertise in polyurethane sandwich panels. Known for combining high performance with aesthetics, Baikal offers an extensive palette of finishes and patterns such as wood, tile, stone, and mosaic prints, appealing to architectural design preferences.

- With annual production capacity of approximately 800,000 m² and a focus on eco-friendly, energy-efficient innovations, Baikal serves both Korean and international markets, including Mongolia. Their commitment to quality, timely delivery, and customer service makes them a competitive player in the industry.

- KBM Trading acts as a major distributor for high quality Korean steel sandwich panels, supplying custom panels and building components internationally. Their network includes top manufacturers, enabling swift fulfillment of orders for diverse industrial and commercial projects.

They emphasize flexible order fulfillment and adherence to international standards, facilitating foreign collaboration and OEM manufacturing partnerships for Chinese factories targeting global markets.

Technology and Quality of Korean Color Steel Sandwich Panels

Advanced Material Technologies

- High Fire Resistance: Korean manufacturers develop mineral wool core panels and flame-retardant PU/EPS panels to comply with stringent fire safety standards, essential for cold stores, industrial plants, and modular complexes.

- Superior Thermal Insulation: Core materials such as PIR and mineral wool provide low thermal conductivity, reducing HVAC costs and qualifying buildings for green certifications.

- Structural Strength: Color-coated steel sheets with corrosion-resistant finishes ensure the panels maintain mechanical integrity in harsh climates.

- Customization: Thicknesses vary widely (typically 50mm to 200mm), with color, texture, gauge, and panel dimensions tailored for project-specific details.

- Eco-friendliness: Increasingly, manufacturers focus on recyclable materials, low-emission coatings, and energy-saving production processes to align with global sustainability goals.

Applications for Korean Color Steel Sandwich Panels

- Prefabricated and Modular Buildings: Panels facilitate rapid construction of schools, clinics, worker housing, and commercial offices.

- Cold Storage and Refrigeration: Thermal and fire safety properties make them prime choices for food storage and pharmaceutical environments.

- Industrial Warehouses and Factories: Optimize space utilization with durable, insulated walls and roofing.

- Transport and Logistics: Used in refrigerated trailers, trucks, and mobile medical units for temperature-controlled transport.

- Commercial Architecture: Panels deliver exterior cladding and interior partitions with attractive colors and textures.

Conclusion

Korea's Color Steel Sandwich Panel manufacturers and suppliers lead the global market through innovation, quality, and versatility. Companies like SY Panel, Sae-Rom Panel, KINDUS, Baikal, and KBM Trading deliver products that emphasize fire safety, superior insulation, structural durability, and aesthetic adaptability. Their panels serve diverse sectors including industrial, commercial, prefab, and cold chain industries, benefiting from Korea's high manufacturing standards and export capabilities.

For Chinese scaffolding material manufacturers seeking to expand OEM services internationally, Korean manufacturers provide a benchmark in technology, quality, and customer service to guide strategic cooperation and product development. Collaborating with or learning from Korean producers will enhance competitiveness in demanding global construction markets.

FAQ

1. What core materials are most common in Korean color steel sandwich panels?

Korean manufacturers typically use polyurethane foam (PU/PUR), expanded polystyrene (EPS), and mineral or rock wool cores depending on fire resistance and insulation requirements.

2. How do these panels meet fire safety regulations?

Panels with mineral or rock wool cores deliver excellent fire resistance. Flame-retardant treated PU/EPS panels also meet national and international fire safety standards.

3. Are Korean sandwich panels customizable?

Yes, manufacturers offer a wide range of panel thicknesses (50mm to 200mm), steel gauges, paint finishes, colors, and textures to match specific project needs.

4. Can they be used for cold rooms or refrigeration?

Definitely. Insulated panels with PIR, PUR, or mineral wool cores are especially suited for temperature-controlled environments like cold storage and refrigerated transport.

5. What advantages do Korean suppliers provide internationally?

Korean suppliers combine cutting-edge manufacturing, stringent quality control, fast delivery, extensive customization options, and compliance with global building codes, making them reliable partners.